Scanning Electron Microscopy Sample Preparation

Luxor Gold and Platinum Sputter Coaters

Sputter coating is a process used to deposit a thin layer of material onto a substrate. In the case of scanning electron microscopy (SEM), this technique is used with metals such as gold or platinum to prepare samples for analysis, offering a range of advantages in improving conductivity, reducing electric charging effects, and even bolstering the level of structural protection against the electron beam.

The main principle of sputter coating involves generating a metal plasma that is deposited on the sample. Spraying must be done in a meticulous and controlled manner, which is why an automated and accurate coating is a much more efficient process than a user-dependent one.

High Quality and Consistency

Produce uniform gold or platinum coatings with excellent adhesion and conductivity, ensured by sophisticated vacuum systems and precise gas flow controls.

Automation and Versatility

Automated coating processes in air or argon complete within only a few minutes, providing a quick route to SEM analysis and helping standardize coating efficiency.

Ease of Use and User Safety

Rigorous quality control and testing ensure that users can always rely on a safe, easy method of homogeneous sputter coating without external interference.

See available configurations

Luxor Product Options

The LUXOR sputter coating systems present an automated and regulated method of depositing consistent layers of gold or platinum. The purpose of the sputtering process is to reduce the electric charging of SEM samples and attain the highest quality of imaging possible. Due to the high conductivity and small grain size of both metals, they offer an enhanced level of secondary electron emission and edge resolution. It is worth noting that platinum has a distinct advantage in ultrahigh resolution applications involving field electron emission (FEG-SEM).

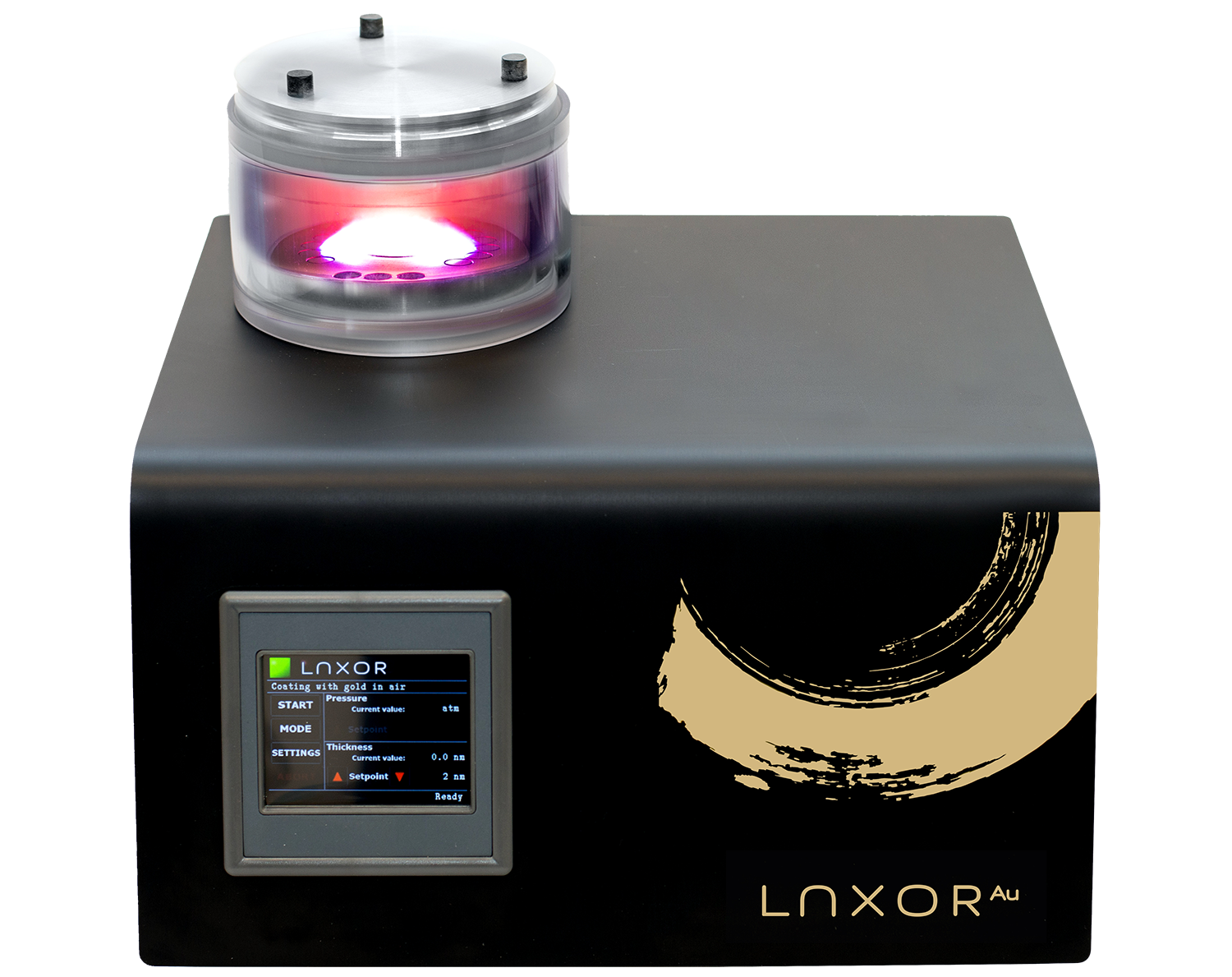

LUXORAu | Gold Sputter Coater

The LUXOR gold sputtering device, LUXORAu, is a specialized tool designed to facilitate the deposition of fine-grain gold coatings ranging from 1 to 100 nanometers in thickness onto scanning electron microscopy samples. This instrument is highly regarded for its ability to produce consistent and uniform gold layers on specimens, thereby providing users with a high degree of reproducibility in their experimental results. The LUXOR gold is capable of enhancing sample electric conduction and significantly boosting secondary electron emission, making it an ideal choice for applications requiring magnification up to 100,000x.

- 100,000x magnification applications

- Strongly increases sample electric conduction

- Boosts secondary electron emission

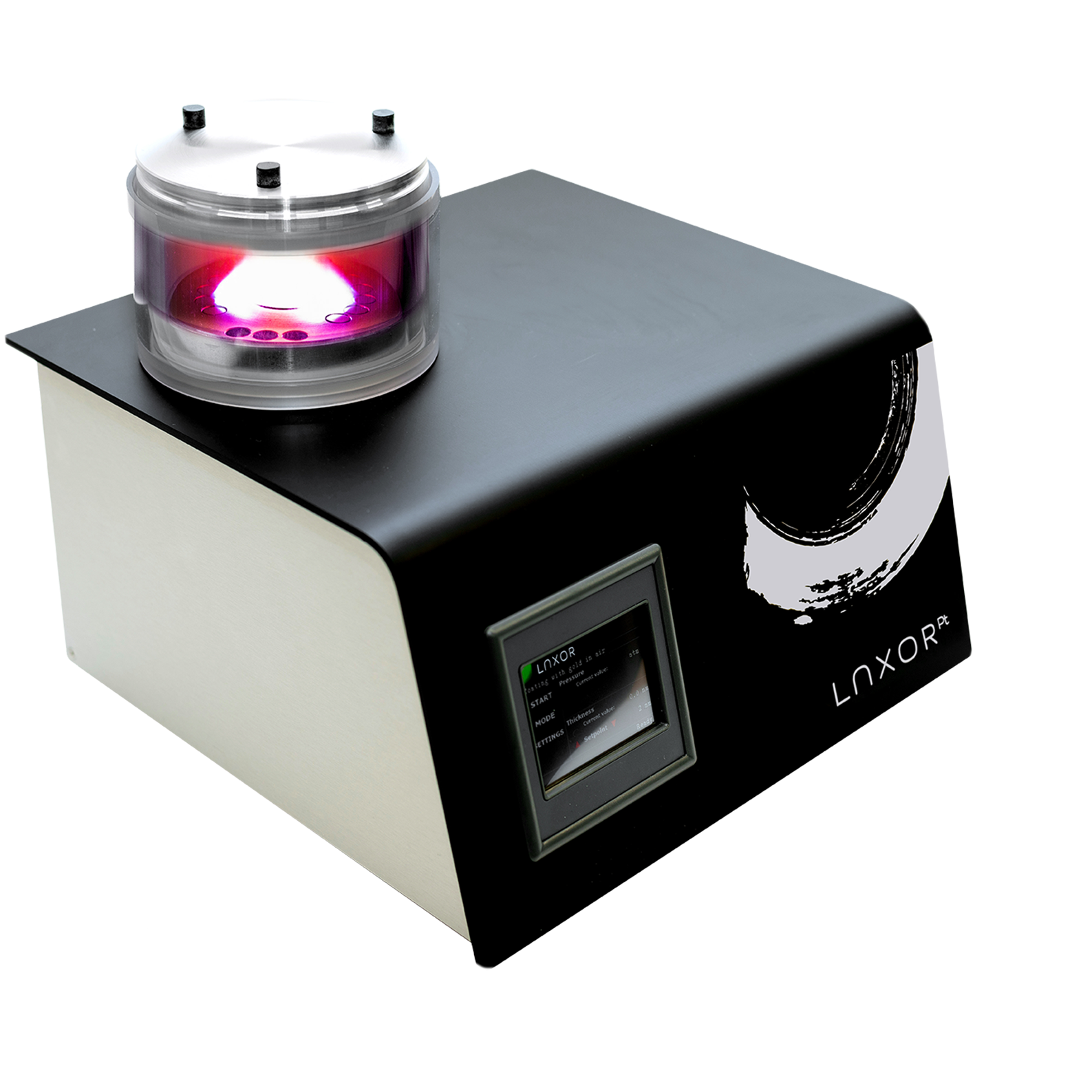

LUXORPt | Platinum Sputter Coater

The LUXOR platinum sputtering apparatus, LUXORPt, is a sputtering device made for field emission electron microscopy — fully compatible with desktop SEMs with a field emission source. Platinum coating is suitable for cases requiring significantly increased magnifications because of high electron emission and the coating thinness (roughly half the thicknesses needed in gold coatings) associated with this metal film. Rather than a vulnerable turbomolecular pump found in different platinum coaters, the LUXORPt employs a dual stage vacuum pump. Beam-sensitive samples receive an extra layer of protection from damage as well with this sputter coater.

- 1,000,000x magnification applications

- Typically relevant in FEG-SEM (field emission gun scanning electron microscopy) for high resolution images

- Various metal compatibilities (both gold and platinum)

- Significantly boosts secondary electron emission