Biolin QCM-D Instruments

QSense™ Omni

The QSense Omni Quartz Crystal Microbalance with Dissipation monitoring (QCM-D) is the most sensitive and automated QCM-D, with the best signal-to-noise ratio of any QCM or QCM-D system available on the market. The Omni combines award-winning design with cutting-edge technology to deliver high-quality data, faster experiments, and simpler workflows.

Highest Sensitivity QCM

Best signal to noise and lowest limit of detection

Fast & Precise Liquid Exchange

Direct injection fluidics minimize unwanted diffusion, delivering more accurate measurements of systems with faster kinetics

Automation

From automated hardware checks to fully-autonomous experiments, the Omni takes automation to the next level

Talk to an Instrumentation Specialist Today!

Gold-Standard Quartz Crystal Microbalance with Dissipation monitoring (QCM-D)

Designed with ease-of-use in mind, the Omni’s completely redesigned hardware works synergistically with the streamlined ‘drag-and-drop’ QSoft protocol-building software to make QCM-D accessible for users of all experience levels. Systems are available with 1-4 measurement channels, offering users the option to start with a single channel and upgrade when project scope expands, or additional funding becomes available. For applications that require extended functionalities such as concurrent electrochemistry or microscopy, the QSense Orbit chamber enables the Omni to utilize a suite of techniques that can be paired with QCM-D measurements for more comprehensive investigation of nanoscale processes.

Measurable Phenomena

Adsorption

Desorption

Binding & interactions

Swelling

De-swelling, crosslinking & collapse

Degradation, corrosion & etching

QSense Omni

QSense Applications

Pharmaceutical R&D

The QSense Omni delivers sub-nanogram level mass sensitivity, making it an indispensable tool for drug development. It has been used extensively by research scientists in the pharmaceutical industry to investigate lipid nanoparticle (LNP) drug delivery systems, study drug-surface interactions, assess biocompatibility of therapeutics, and develop biosensors.

Biotechnology & Medical Devices

The label-free QCM-D technique is useful for simulating interactions and reactions taking place at surfaces and interfaces within the human body. Biomolecular interactions that have been studied using QCM-D include immune responses to surgical implants and biomaterials, antibody-antigen interactions, protein-DNA interactions and conformational changes, biomineralization, and fouling due to biofilm formation.

Cleaning & Detergents

QCM-D provides real-time insights into the removal of mass from a surface, which is ideal for studying the efficacy of cleaning products on hard surfaces. By flowing detergent formulations with different surfactant concentrations over a sensor coated in the material of interest (lipids, fat, grease, food, biofilms, soil, etc.) it is possible to quantify their cleaning performance. High temperature and/or high-pressure environments such as industrial cleaning tanks can be simulated using the QSense High Temperature/High Pressure Chamber.

Batteries & Energy Storage

QSense QCM-Ds can be connected to a potentiostat to enable Electrochemical Quartz Crystal Microbalance with Dissipation monitoring (EQCM-D) experiments. EQCM-D allows in situ investigation of bulk and interfacial behaviors in batteries, fuel cells, and other energy systems, providing a better understanding of both the chemical reactions and mass transport taking place during their operation. One critical application of EQCM-D is furthering our understanding of the Solid Electrolyte Interphase (SEI), which is critical for improving Li-ion battery performance.

Electronics & Semiconductors

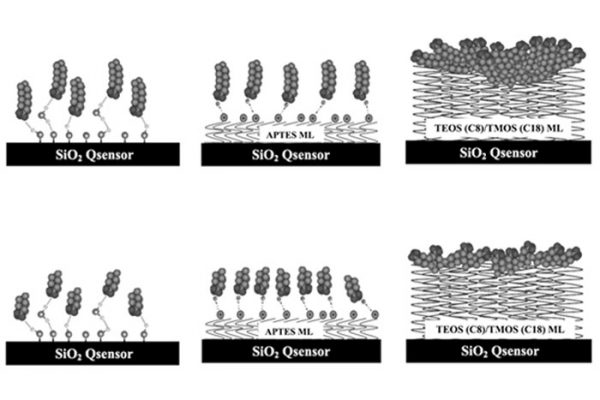

Semiconductor wafers undergo several treatments as part of the Chemical Mechanical Planarization (CMP) process to ensure they meet specifications and are prepared for subsequent photolithography and metallization steps. QCM-D can be used to gain a better understanding of the interactions taking place between the surface and slurry, the etching behavior of different slurry formulas, and the cleaning performance of post-CMP residue removal agents. Examples of available sensor coatings for CMP-related studies include: Cu, Co, W, Al, Sn, Si, SiO2, Si3N4, SiC, TEOS, polySi, Al2O3, CuO, SnO2, NiP, polyimide, and many more.

Food Science

QCM-D is a useful tool for food science applications ranging from food ingredient interactions to food engineering and processing, and food safety and storage. Various systems can be modeled using QCM-D, such as the human tongue and oral cavity, food manufacturing lines, and food packaging, to study the molecular interactions that affect food quality, appearance, sensory characteristics, shelf life, and more.

Polymers

When studying polymers, it is critical to understand both their mechanistic properties and their chemical attributes. QCM-D enables researchers to better understand the dynamic behavior of polymers, such as swelling or shrinking in response to stimuli like pH or salt concentration, by providing simultaneous measurements of mass and viscoelastic properties of the adsorbed polymer layer. The sensitivity and precision of QCM-D make it useful for investigating polymer adsorption, conformational changes, and stability of polymer layers under varying conditions.

QSense Omni

Product Features

Measurement Conditions

Flow Mode

Stagnant Mode

Liquid Phase

Gas Phase

*Requires Add-on

Harsh Chemicals

Low Temperature

High Viscosity

Inert Surface

*Requires Add-on

Mass Sensitivity & Signal Quality

Smart Automation

Pre-program experimental protocols and let Omni do the rest! Several automated features have been engineered into the QSense Omni to boost experimental reproducibility and eliminate user error or user-dependent variation. Before an experiment can be initiated, the QSoft Omni protocol builder and data acquisition software completes automatic system checks to ensure that the experimental conditions are optimal. After running the experiment, the Omni will self-clean and run post-experiment checks to ensure it is ready for the next measurement.

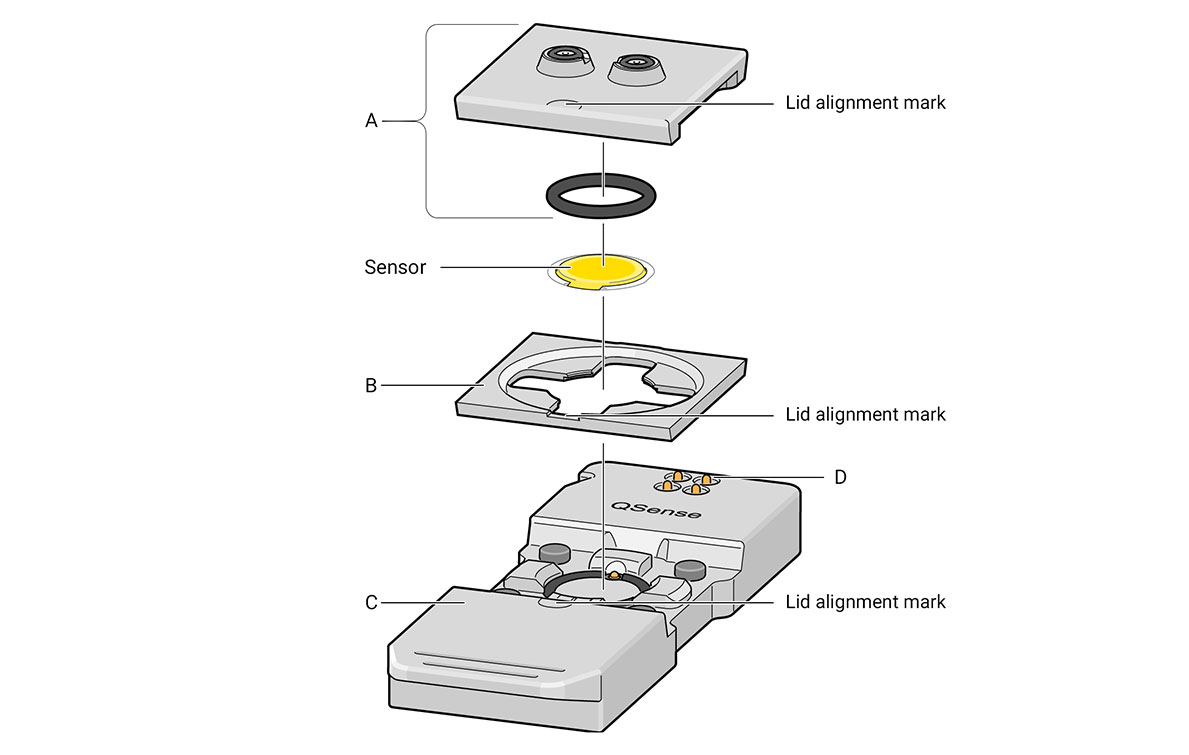

Correct & Repeatable Sensor Position

The new sensor mounting guide, along with automated system quality checks in the QSoft software, work together to ensure the sensor is mounted correctly for each measurement, and conditions are ideal for experiments to start. Using these new features in practice translates to 25-times less user-variability in the QCM-D data and improves thickness measurements of ex-situ coated films. The redesigned flow module automatically locks the sensor in place, and acts as a Faraday cage, leading to high-quality data with minimal drift.

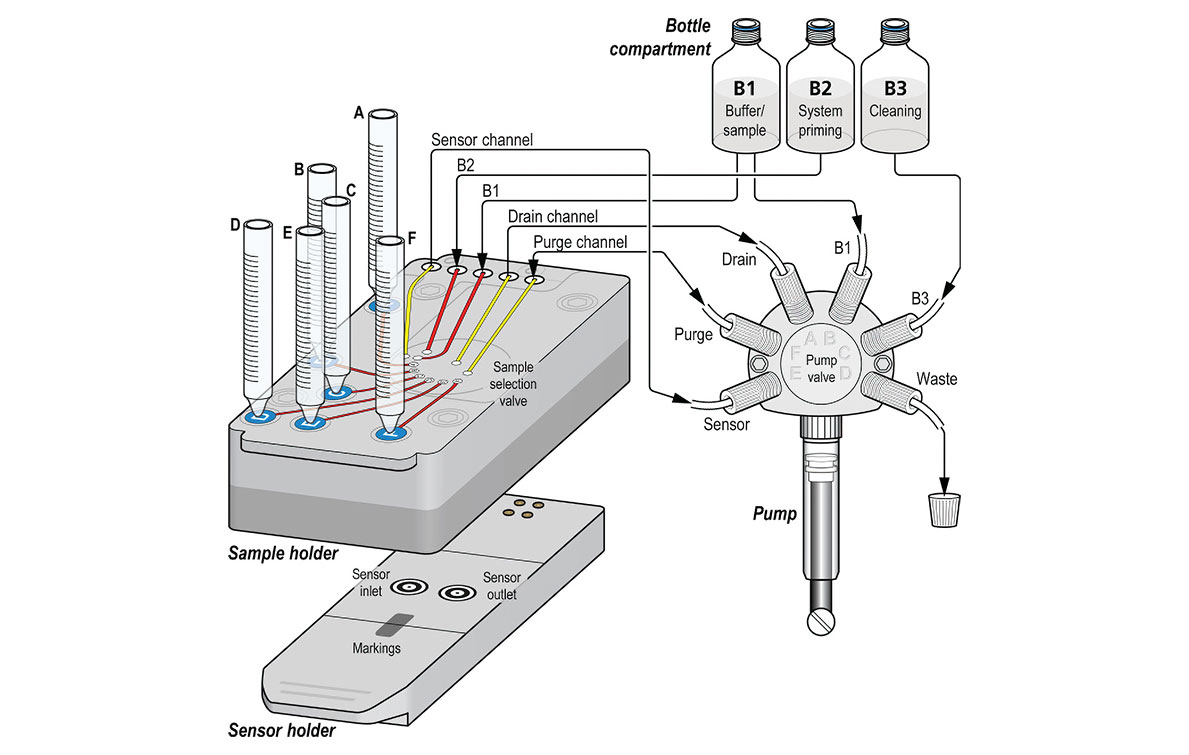

Fast & Precise Liquid Exchange

The QSense Omni uses an entirely redesigned fluidics system that maximizes efficiency and provides faster and sharper sample delivery, resulting in more accurate data. The direct-injection fluidics system integrates sample storage in the unit for better temperature control and eliminates tubing. Liquid handling is fully automated, preventing the introduction of air into the flow system. By delivering the liquid samples directly onto the sensor surface, less liquid volume is required for the experiment, unwanted diffusion is minimized, and kinetics measurements of faster systems are possible.

Exceptional Temperature Range, Stability, & Resolution

The frequency and dissipation parameters measured by QCM-D are temperature dependent, making temperature control and stability paramount. The QSense Omni’s patented temperature control chamber is integrated into the QCM-D unit, maintaining the same temperature zone for the sensor holder and sample vials. This unique chamber ensures that the sample temperature remains stable over a range of 4° C to 70° C throughout experimental runs, with ±0.003 °C long-term stability.

Sampling Speed

The sampling rate, also referred to as time resolution, is the number of data points collected per second. Instruments with higher sampling rates can resolve the kinetics of faster processes. The Omni’s sampling rate is the highest of any QCM available, measuring 300 data points per second. While higher sampling rates typically lead to increased noise in the data, the Omni’s sophisticated hardware minimizes noise, even in its high-speed sampling mode.

Measurement of Multiple Harmonics

QCM-D is an acoustic-based technique, which involves the measurement of frequency and dissipation parameters to characterize mass changes and viscoelasticity in thin film systems. Measuring the fundamental frequency is a given in QCM, but measuring multiple overtones (harmonics) provides a deeper understanding of the adsorbed layer, especially if it is soft (viscoelastic) rather than rigid. All QSense systems measure multiple harmonics, up to the 13th overtone. To learn more about the value of measuring multiple harmonics during QCM experiments, read our White Paper:

Widest Range of Sensor Surfaces

Having your material of interest on the surface of the sensor is a prerequisite to achieving your research goals with QCM-D. QSense offers over 100 different sensor surfaces, including common metals, polymers, ceramics, and glass used across various industries, sulfides and oxides, functionalized surfaces, and custom options for exotic materials.

Application Support & Local Service

In the US and Canada, the QSense QCM-D products are supported and serviced by Nanoscience Instruments. We pride ourselves on providing exceptional application support and field service, ensuring your team of users is well-trained and the instrument is up and running in optimal condition. Whether you are interested in discussing the feasibility of a specific experiment or need help with troubleshooting your QSense system, our Support teams are here for you!

QSense Omni

Product Accessories

QSense Orbit

The Orbit chamber enables use of QSense modules to expand experimental setup possibilities and combine QCM-D with other techniques. Compatible modules include: electrochemistry, window (optical access), open (direct sensor access), among others.

QSense Modules

The QSense QCM-D systems come equipped with standard flow modules, which enables a wide variety of aqueous and gas-phase experiments. Many other specialized modules are available to support experiments that require the use of additional technologies.

QSensors

QSense Omni

Qsense Software

QSoft Omni | Build the Experimental Protocol

QSoft Omni is a unique software platform designed specifically for building and controlling experiments when using the QSense Omni QCM-D. The drag-and-drop user interface, along with live script editing capabilities, make it straightforward to create and modify experimental protocols. Quality control is built into the software, with automated checks running in the background throughout the setup process to ensure all conditions are optimal before the measurements begin. Throughout the experiment, data is logged comprehensively. Both automated actions and user annotations are carefully documented, providing a detailed record of the experiment’s progression.

DFind | Analyze the Data

The QSense DFind software helps to streamline data analysis by integrating data preparation, modeling, analysis, and reporting into one convenient platform. Featuring a step-by-step, guided modeling process and vast library of sensor surface materials, QSense DFind simplifies data interpretation and removes many of the perceived barriers to QCM-D analysis. DFind also supports simultaneous multi-dataset analysis, making it particularly useful for research that involves comparing or combining data from multiple different experiments.

Discover QSense DFind and learn tips and tricks from the QCM-D experts at Biolin Scientific:

QSense Omni

Product Knowledgebase

Webinar

Molecular Scale Adsorption Behavior of Per- and Poly-Fluoroalkyl Substances (PFAS) on Model Surfaces

Per- and poly-fluoroalkyl substances (PFAS) are emerging contaminants of concern owing to…

Blog

Advanced Automation Features of QSense Omni for Maximizing Efficiency

Quartz Crystal Microbalance with Dissipation monitoring (QCM-D) has revolutionized surface…

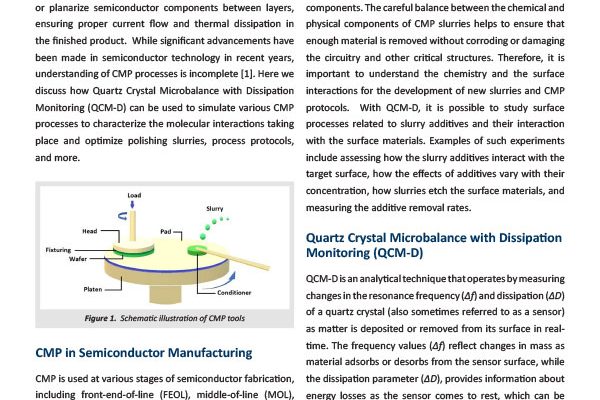

White Paper

Optimizing Chemical Mechanical Planarization (CMP) Processes with QCM-D

Chemical mechanical planarization (CMP), also called chemical-mechanical polishing, is a c…