QSense Knowledge base

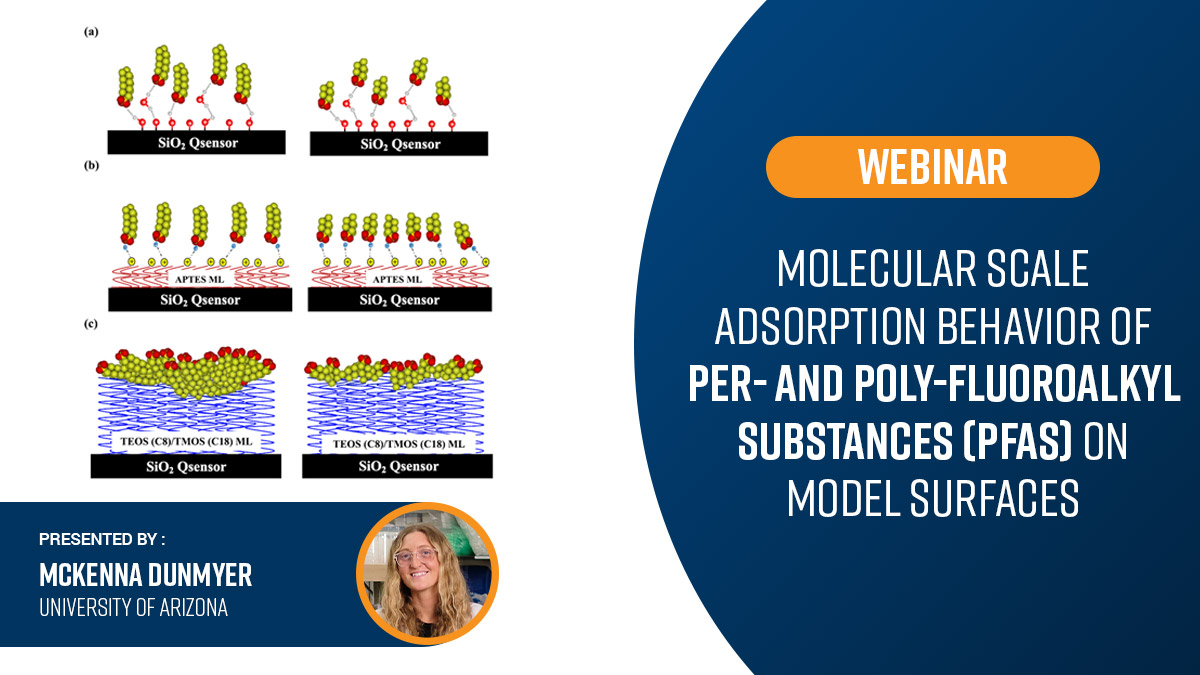

– Webinar –

Molecular Scale Adsorption Behavior of Per- and Poly-Fluoroalkyl Substances (PFAS) on Model Surfaces

Per- and poly-fluoroalkyl substances (PFAS) are emerging contaminants of…

– Tech Note –

Optimizing Chemical Mechanical Planarization (CMP) Processes with QCM-D

Chemical mechanical planarization (CMP), also called chemical-mechanical polishing, is…

Product Brochure

Product Overview

QSense provides a unique solution for you to understand the surface interactions of oil components, additives and other relevant chemicals in real-time.

QSense High Pressure gives you the additional possibility to explore more with experiments closer to real-life conditions. Whether you are struggling to increase oil yield, prevent fouling of pipes, or find an optimal lubricant for engines, it is valuable to understand your processes better.

With QSense High Pressure you can make smarter decisions based on information about the real-life surface interaction processes.

Test Under High Temperature & High Pressure Conditions

Explore the molecular interactions of your material up to 150°C and up to 200 bar

Experimental Flexibility

Design custom sensor surfaces with your material of interest and switch between sample liquids for accurate measurement of nanoscale interactions

Talk to an Instrumentation Specialist Today!

QSense High Pressure Chamber

Product Applications

Flow Assurance: Prevent Fouling

Fouling and clogging of pipes can be a costly problem. Added chemicals are commonly used for flow assurance.

Examine fouling processes to find methods or additives to minimize the problem. Use carbon steel sensors to mimic the surface of pipelines and study adsorption and release of crude oil/asphaltenes under different conditions. Experiment with chemical composition, surface material, prressure and temperature.

Oil Recovery: Enhanced Oil Recovery

Extraction of oil from underground reservoirs or tar sands require carefully considered process conditions. Use scientific analysis to find your way to optimize.

The use of polymers and surfactants can change the viscosity of the injected water and the wettability of the rock to dissolve oil from the mineral. Measure the adsorption of polymers or surfactants and the release of oil from a mineral sensor to optimize your chemical solutions and increase your yield. Less surfactants used gives a more environmentally friendly solution and reduces costs.

Oil Recovery: Bitumen Liberation

Extracting bitumen from oil sands can be difficult. A silica sensor coated with bitumen can simulate the oil sand and enable analysis of the bitumen liberation process.

Study the bitumen detachment to find the optimal conditions of e.g. pH and temperature to maximize the recovery.

Fuels and Lubricants: Optimize Engine Lubricants

Lubricants are used in numerous applications to control friction and increase the lifespan of moving parts. These fluids consist of a variety of surface active chemistries competing for the surface.

Understanding the nature of adsorption of surface active chemicals is key to finding a well-balanced lubricant. Study the effect of fuel and lubricant additives in engines with a stainless steel sensor. Observe the adsorption in real-time to find the delicate balance of chemicals for optimal performance.