The interaction between a liquid and a solid surface is a critical descriptor for a surface’s chemistry with important technological implications: it can determine how well coatings will adhere, detect the presence of soils or contaminants, and ascertain the compatibility of surfaces with biologics to name a few.

To quantify wetting, or the equilibrium interactions at a liquid, solid, and vapor interface, contact angle measurements are typically performed with an optical tensiometer (also known as a goniometer). In this measurement, a video recording of a liquid droplet on the sample surface is analyzed to calculate the angle that results at the edges of the droplet. This angle is a function of the chemistry and magnitudes of the liquid’s surface tension, the solid’s surface energy, and the interfacial tensions between the liquid and solid. With the use of different sample (probe) liquids, the interactions between the liquid and solid surfaces can be quantified. Traditional optical tensiometers use pipettes or syringes to deposit liquid droplets onto the surface. However, if the samples are small and nearly microscopic, the volume of liquid dispensed could be too large and overflow the sample surface thereby making the contact angle measurements nearly impossible. Some examples of small surfaces that are relevant include small fibers or wires, a thin medical device tubing or catheter, a micro-fluidics or electronics chip, the razor’s edge of a sharp object, or any other small feature. How can we access the wettability of these small surfaces or discrete sample areas that are smaller than a millimeter?

The simple answer to measuring the wettability of smaller surfaces is to use smaller droplets. While this logic is easily followed, dispensing small droplets can be challenging. For example, a 30-gauge needle with a diameter of 0.3 mm can consistently deliver droplets in the range of ~0.2-0.5 microliters. While this sounds small and is indeed a relatively small droplet, depending on the contact angle, it can still have a diameter of multiple millimeters. To truly access small areas, we need to go down from microliters and move right into the scale of picoliters.

Piezoelectric Inkjet Technology for Small Droplets

Piezoelectric inkjet dispensing, a technology that has been developed extensively for printing applications, can be used to dispense picoliter-sized droplets. This technology functions by using a piezoelectric dispenser head that has a reservoir of liquid inside a diaphragm and a small opening. By applying a voltage in the form of a rapid pulse, the piezoelectric diaphragm is compressed, resulting in the ejection of a droplet from the opening. Depending on the size of the dispenser head orifice and the pulsing sequence, single or rapid bursts of picoliter-sized droplets can be dispensed onto a surface. These droplets can then be analyzed using a high-image-resolution optical tensiometer.

Picoliter Contact Angle Measurements on a Chip

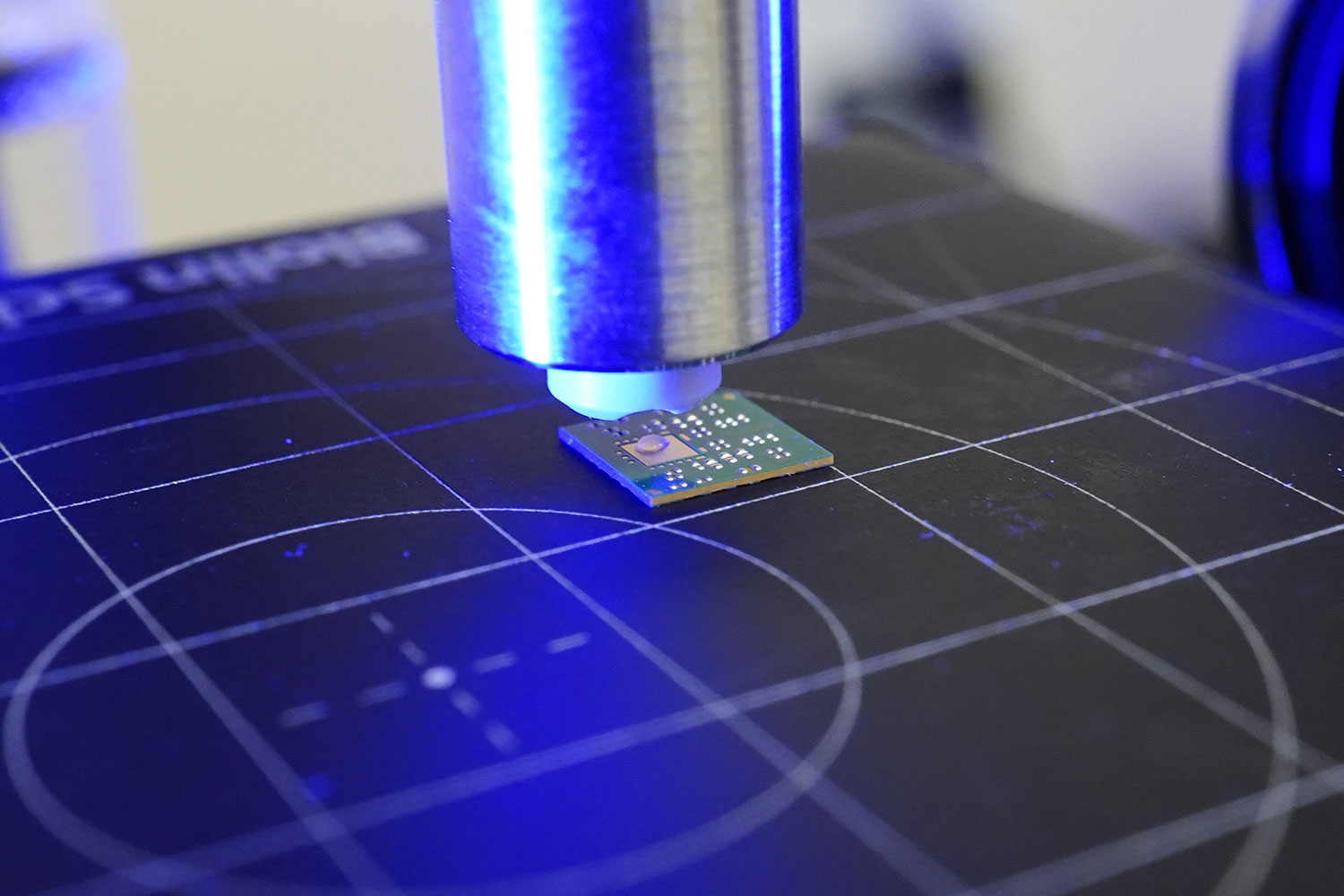

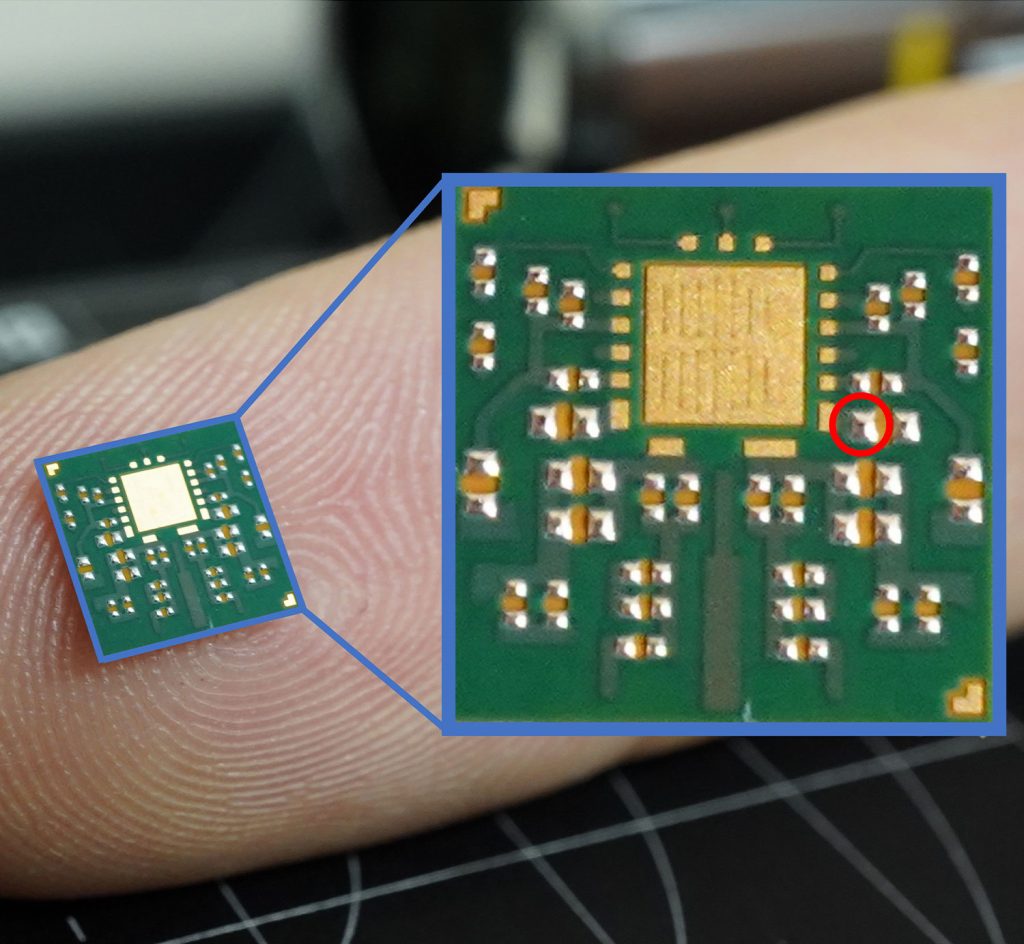

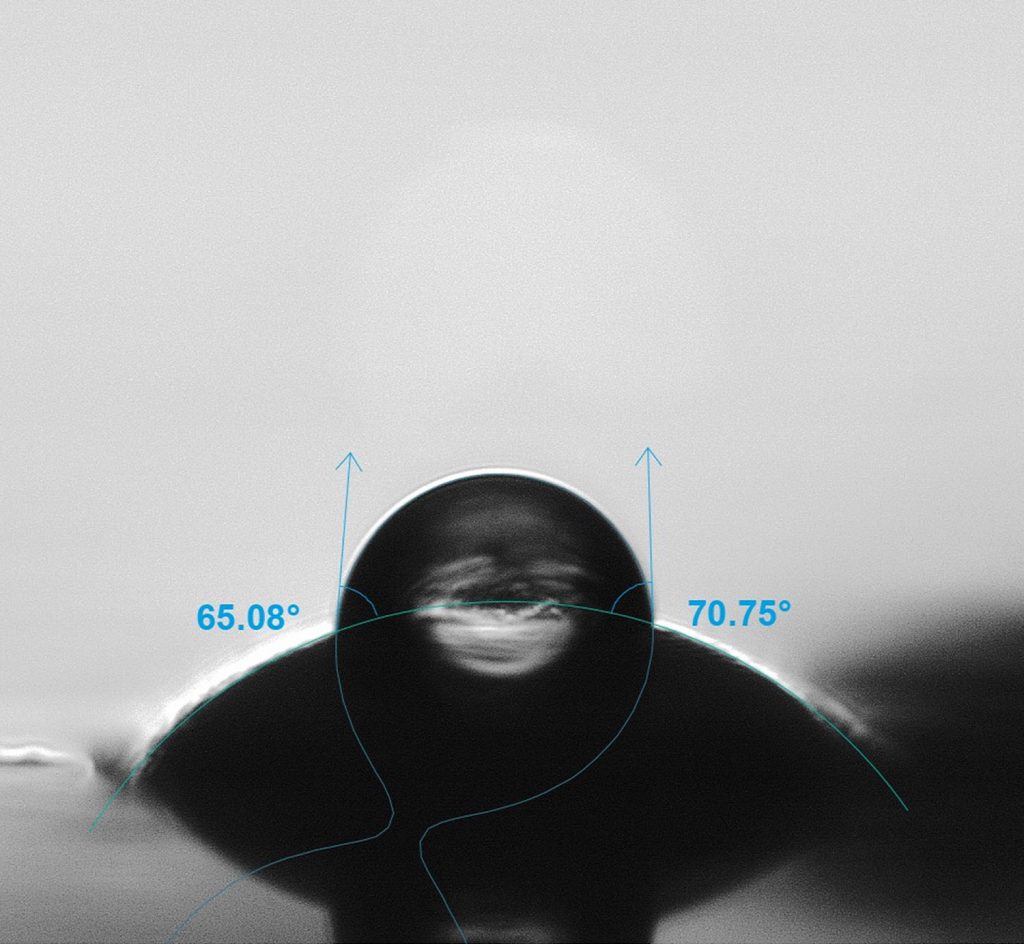

To demonstrate the scale accessible with picoliter-sized droplets, we measured the contact angle on a single solder bump on an electronics chip. In Figure 1, we can see the circuit board fits onto the tip of a finger and contains many small shiny spots, that with some additional magnification can be identified as solder bumps. We then used a piezoelectric inkjet dispenser integrated with the Theta Flow Optical tensiometer to dispense a ~70 picoliter-sized water droplet onto the specified soldered bump. The analyzed droplet image with a mean contact angle of 67.9° is shown in Figure 1 (right). In this droplet image, we also observe a distinct curvature of the surface feature. If the baseline of the droplet is fitted to a flat surface, the contact angle will be overestimated. With the OneAttension analysis software included with the Theta Flow tensiometer, we can take advantage of the circular baseline feature to get an accurate contact angle measurement on curved surfaces, even with picoliter-sized droplets. Here, the curved baseline precisely traces the curvature of the feature, giving an accurate contact angle on this curved surface that is less than ~200 um in diameter.

Attension Pico Liter Dispensing Solutions

The Attension Theta Flow and Flex tensiometers can be integrated with the most versatile picoliter dispensing solutions available on the market, with multiple dispenser nozzle sizes to accommodate a droplet range of 20- 380 picoliters and liquid viscosity ranges of 0.4 to 20 mPa. If higher viscosity liquids are necessitated, a nozzle heater can be included to increase the max viscosity limit to 100 mPa. The dispensing drop volume and velocity can be further fine-tuned by adjusting the voltage and pulse width. By programming a burst of multiple drops per measurement, we can further increase the droplet volume to easily access droplets in the nanoliter range. Since the volumes are so small, appropriate optics are needed to visualize the individual droplets. The magnification range of the Theta Flex and Theta Flow models is sufficient to image the small droplet volumes. Additionally, sample holders for single fibers and thin films ensure easy and reproducible sample assembly. Coupled with the industry-leading camera image resolution of the Theta Flow optical tensiometer, the most accurate contact angles are possible from droplet images at the smallest scale.