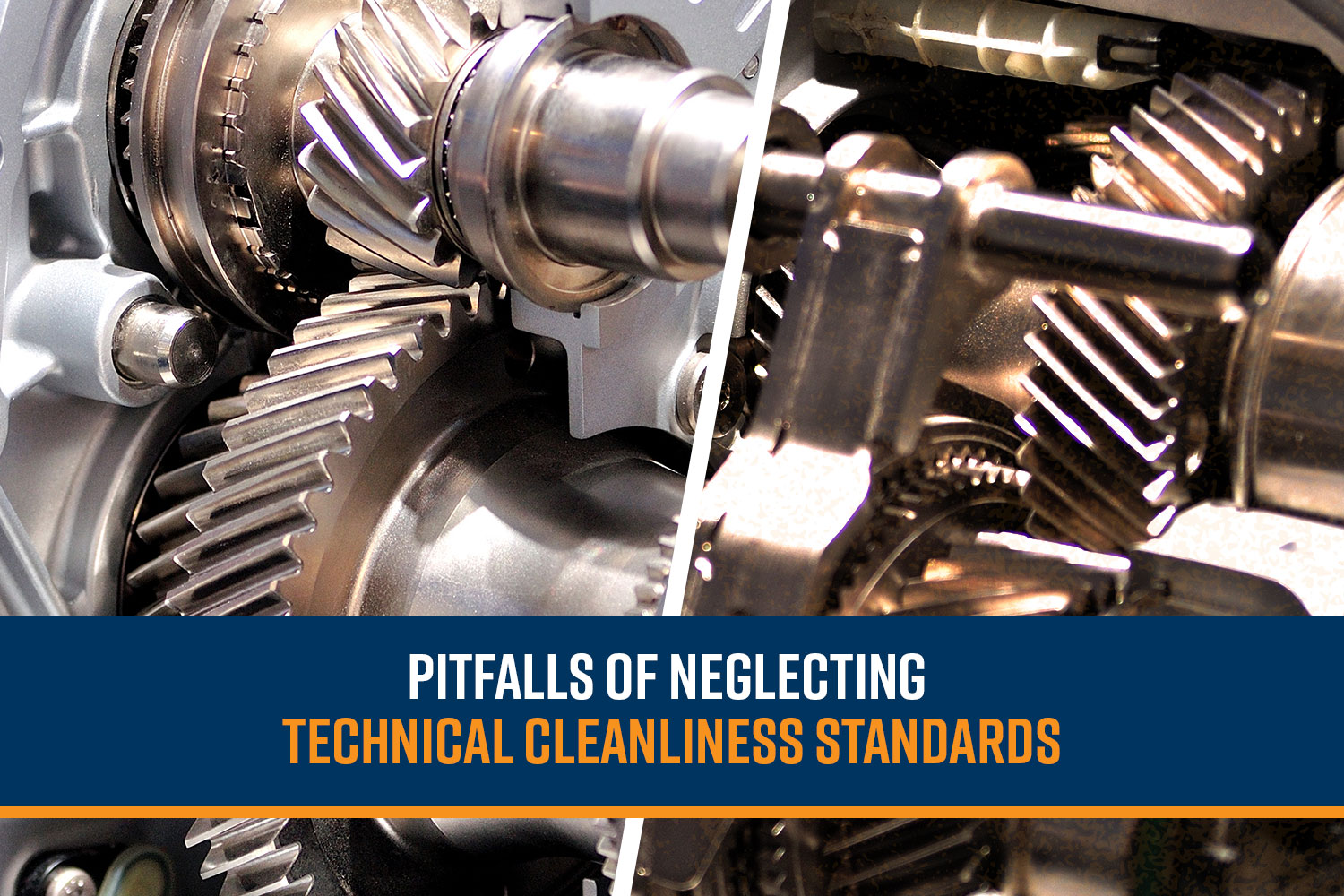

Precision manufacturing is a process that emphasizes exact specifications and extremely tight tolerances within fabricated components. Within this domain, the term technical cleanliness (TC) refers to the rigorous control of particulate matter clinging to the surface of parts and products. Though microscopic, these unwanted particles lead to detrimental effects on performance and quality and stand as a formidable challenge in ensuring every component – every finished product – meets the exact standards of cleanliness.

Technical cleanliness has become an essential criterion for maintaining the integrity of manufactured parts in a wide array of industries, including automotive, aerospace, optical, pharmaceuticals, medical devices, and electronics. This analytical concept extends the traditional notion of cleanliness from macroscopic, visible dirt present on the surface of materials into the microscopic realm, focusing on the particulate contaminants that, although minuscule, have profound impacts on the functionality and longevity of products employed in day-to-day use.

Costs of Contamination

Although the costs of implementing and maintaining cleanliness standards may be significant, they are often dwarfed by the expenses associated with addressing contamination issues post-production. The ramifications of particulate contamination extend far and wide, affecting not just the functionality of products but also posing broader implications for manufacturers and industries at large. These costs can be categorized into direct and indirect impacts, each carrying its own set of hefty consequences.

Direct Consequences

These are tangible, immediate results of lackluster cleanliness.

- Outright product failure

- Significant degradation of product performance

- Particles of the wrong size, type, or quantity can:

- Obstruct mechanical processes

- Cause wear and tear

- Lead to electrical failures

- Increased production costs

- Higher rates of product returns

- Extensive warranty claims

Indirect Consequences

Inadequate cleanliness can compound the financial strain on businesses along with intangible costs.

- Damaged company reputation

- Decreased customer trust and loyalty

- Regulatory penalties

- Increased insurance costs

- Potential legal challenges

- Diverted resources to address cleanliness failures

- Stymied company development and growth

As such, investing in cleanliness and contamination control is not merely a regulatory compliance or quality assurance measure; it is rather a strategic investment in the company’s long-term viability and success.

Challenges in Maintaining Cleanliness

Maintaining technical cleanliness across industries presents a multifaceted obstacle, compounded by the intricacies of modern manufacturing environments and the microscopic scale at which detrimental particles operate. To pinpoint the key factors contributing to the difficulty of ensuring consistent TC analysis:

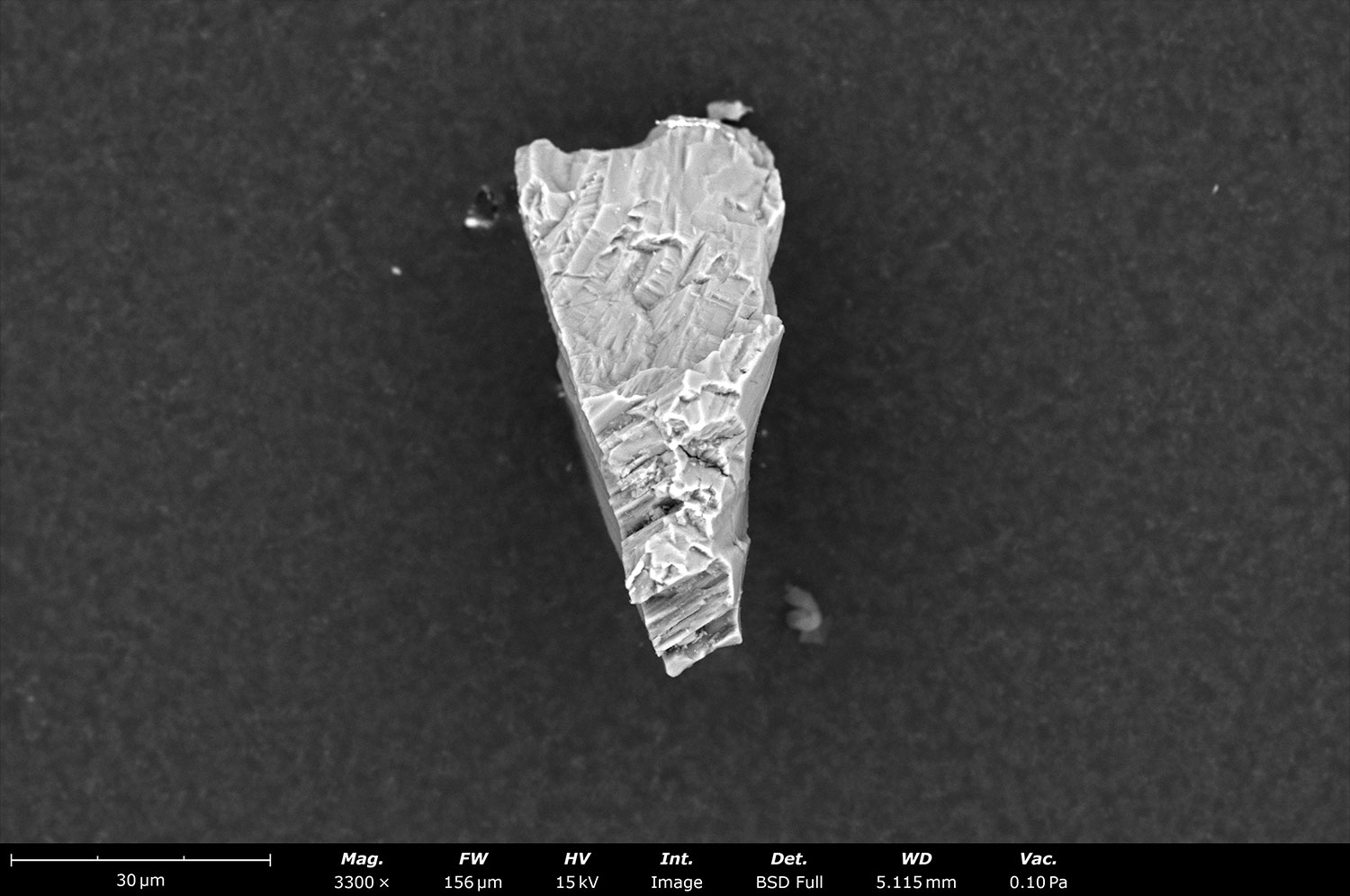

The chief hurdle with TC tends to be the precise detection and accurate analysis of particles. Given the microscopic size of many particles of concern, traditional visual inspection methods – including the use of optical microscopes – often fall short. They may not detect the most critical of small particles, leaving opportunity for them to cause significant issues in products. In addition, visual inspection with light microscopes relies heavily on the skill and vigilance of the operator.

Beyond detection, quantifying and analyzing these particles, at least to a meaningful statistical degree, pose more layers of complexity. Manual measurements are far too time-consuming for statistically relevant datasets, and bulk chemical analysis may not provide the detailed elemental composition of individual particles necessary for identifying their source or potential impact on the product.

Maintaining an environment conducive to TC involves controlling numerous factors: air quality, humidity, and the actual cleanliness of equipment and materials. Fluctuations in these conditions can introduce new contaminants or exacerbate existing issues, making consistent cleanliness a moving target.

As industries evolve and advance, new materials may shed particles differently or require novel cleanliness protocols, necessitating continuous adaptation of cleanliness standards and detection methods.

The Need for Advanced Particle Analysis

As industries strive to meet increasingly stringent standards for TC, the limitations of traditional methods for particle detection and analysis become strikingly more apparent. These conventional approaches, while foundational, often fall short in addressing the full scope of cleanliness requirements in today’s high-tech manufacturing environments.

Limitations of Traditional Methods

Resolution and Detection Limits

Visible light microscopy struggles with the detection of very small particles, those that are often most critical to product performance and safety. Its effectiveness is limited by the optical resolution of the microscope, skill of the operator, and the physics of light diffraction.

Time-Consuming Processes

Manual methods are both labor-intensive and time-consuming, requiring significant human effort and expertise, which can lead to bottlenecks in quality assurance processes.

Lack of Comprehensive Data

Bulk chemical analysis provides an overall composition of contaminants but lacks the granularity to identify the elemental makeup of individual particles. This limitation makes it difficult to pinpoint the source of contamination or to understand its potential impact on the product.

Scanning Electron Microscopes for Technical Cleanliness

To overcome these limitations and propel TC analysis into the next regime, industries are turning towards more sophisticated and automated methods, such as scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS). This combination offers a multitude of key advantages:

High-Resolution Imaging

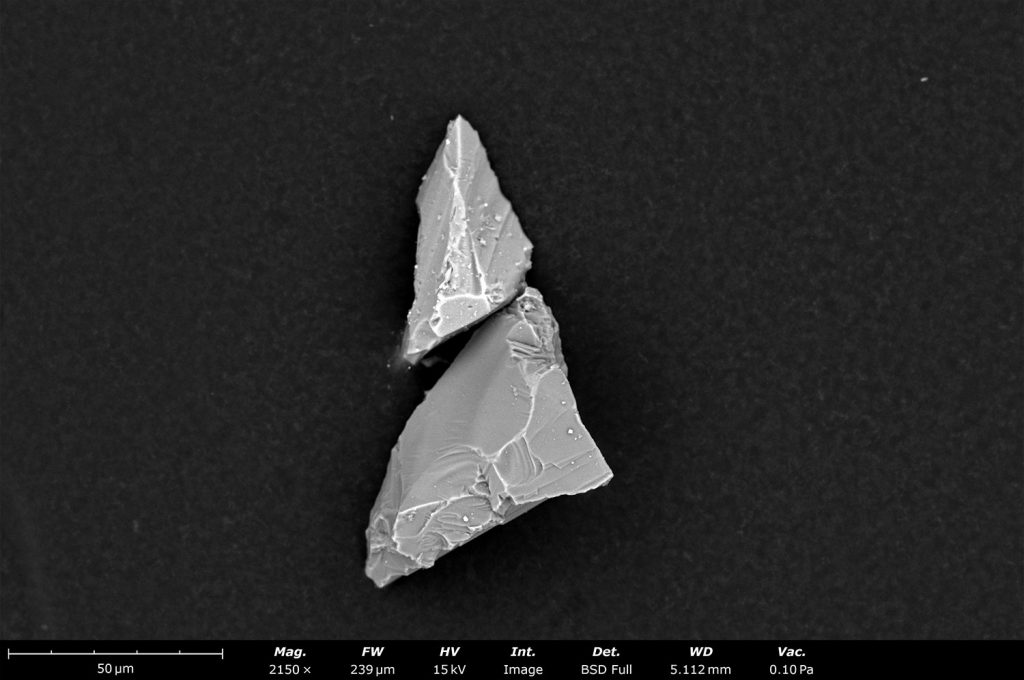

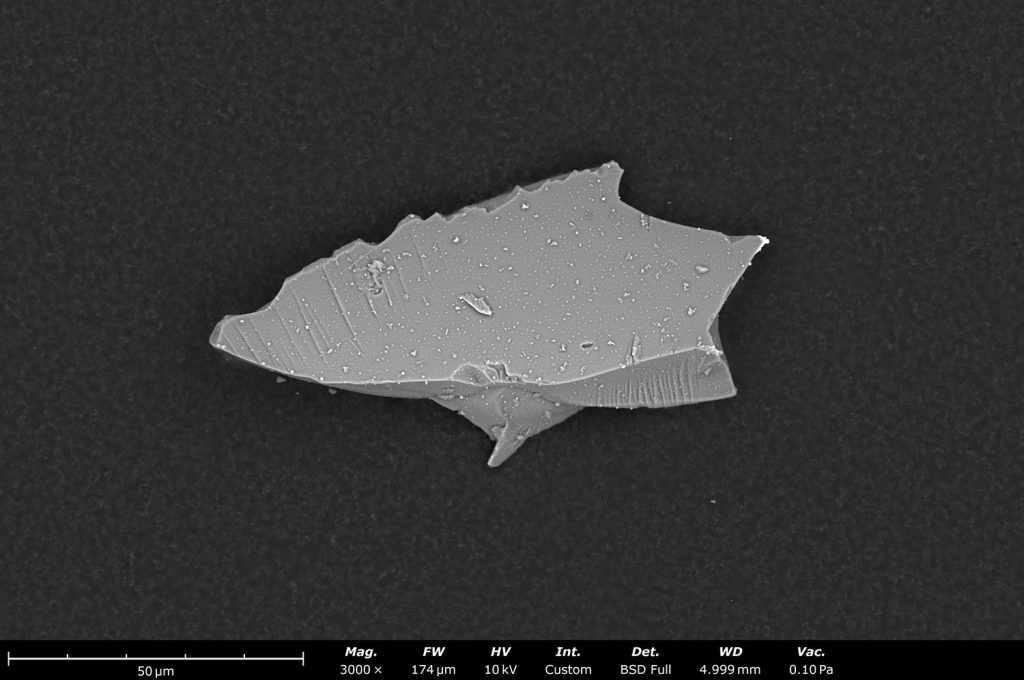

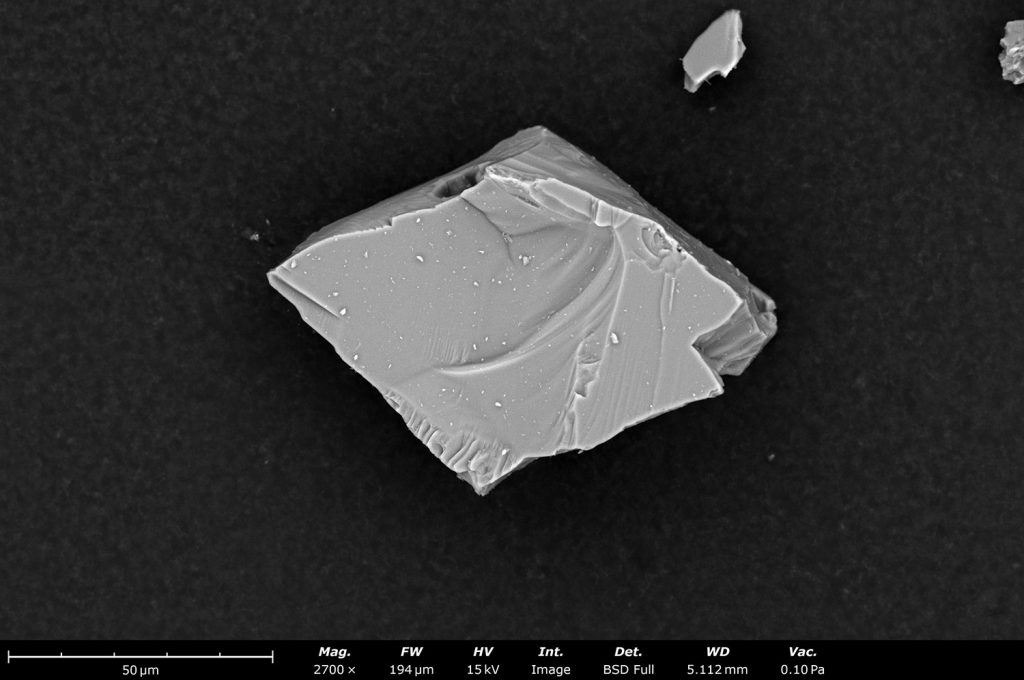

SEM, with its nanoscopic electron beam, provides high resolution images that reveal the morphology and size of particles much smaller than those detectable by optical microscopy. This capability is crucial for identifying contaminants that could compromise the functionality or integrity of fine components.

Elemental Composition Analysis

EDS is an X-ray-based technique that offers detailed elemental analysis of particles detected by SEM. This feature is invaluable for tracing the source of contamination, as it allows for the identification of materials and possible points of ingress within the manufacturing process.

Automation and Throughput

Automated SEM/EDS systems can process a large number of samples with minimal human intervention, significantly reducing analysis time and the potential for human error. This efficiency is vital in maintaining high throughput in demanding production environments.

Data Integration and Reporting

These systems can also integrate analysis data into comprehensive reports that support decision-making processes, from quality control to entire process improvement. The ability to automatically generate detailed documentation aids in compliance with industry standards (an example would be ISO16232/VDA 19 for the automotive industry) and diverse regulatory requirements.

Conclusion

The transition towards automated SEM/EDS analysis reflects a broader trend in industry towards leveraging technology to enhance quality control and assurance. By providing detailed, particle-by-particle analysis, these advanced systems play a pivotal role in identifying contamination sources, understanding their implications, and driving continuous improvement in technical cleanliness. The adoption of such technologies not only addresses the limitations of traditional methods but also aligns with the push for greater efficiency, accuracy, and reliability in manufacturing.

Additional Resources

For further exploration into addressing technical cleanliness standards with automated SEM / EDS characterization and data analysis, please read our white paper on the topic.