Welcome back to the next issue of SEM Insights. In addition to the regular updates, in this issue we take a deeper look into preventative maintenance (PM) of your Phenom SEM. Why should you schedule regular PM? What does PM involve? Should you consider a Service Maintenance Agreement (SMA)?

Warm regards,

– The Nanoscience Instruments Team

FROM OUR APPLICATIONS LAB

Phenom Updates

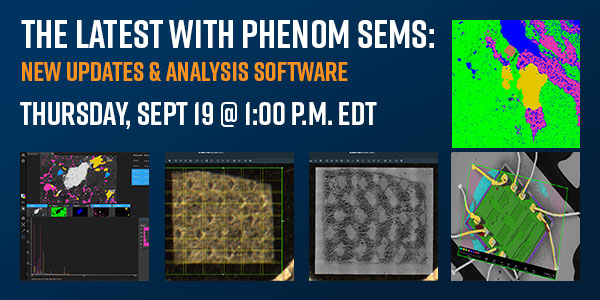

We recently held a webinar highlighting the latest updates of the Phenom SEM. In case you missed it or would like to review the content again, you can watch it on demand at the link below.

Three New Phenom Features

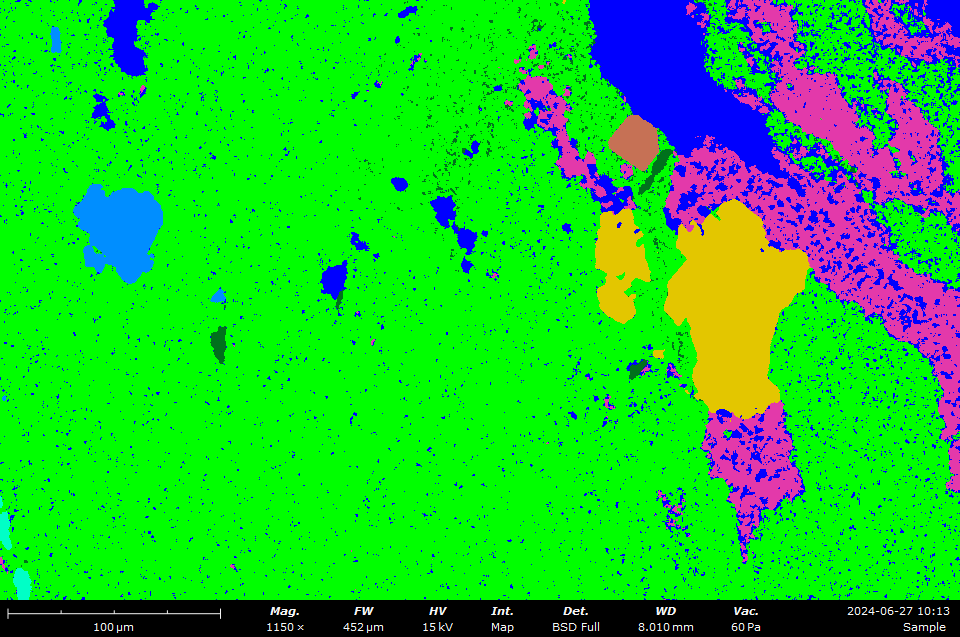

ChemiPhase

Pixel-by-pixel material phase grouping creates elementally similar regions based on EDS map data.

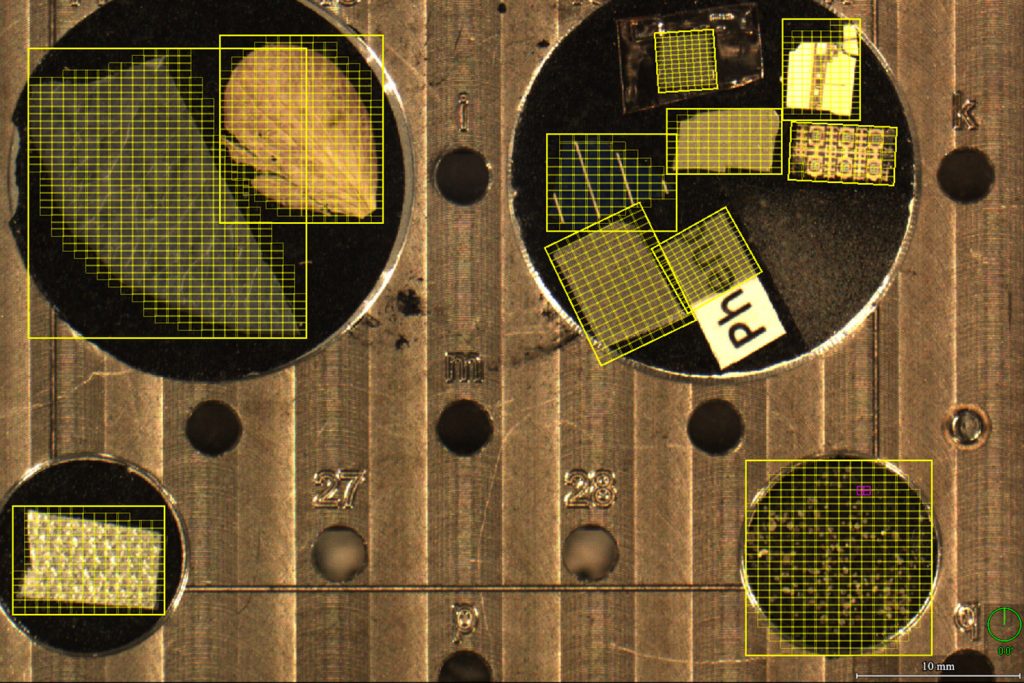

MAPS

MAPS is a unique software feature that lets users correlate data from various imaging techniques. It also features the ability for large area EDS analysis, high resolution SEM image stitching, and multimodal workflows.

PHENOM MASTERCLASSES

The recordings of all our masterclasses are available on demand. They are advanced learning pathways to deepen your SEM proficiency.

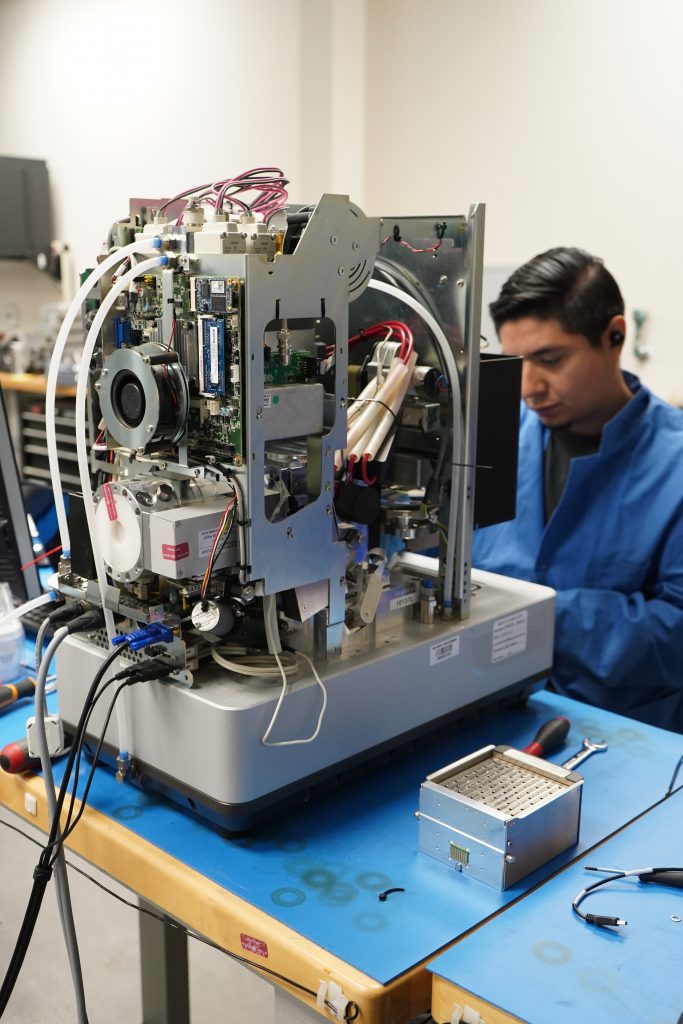

FROM OUR SERVICE DESK

Preventative Maintenance (PM)

Adhering to a regular maintenance schedule is the key to ensuring the optimal performance and longevity of your Phenom SEM. The suggested PM interval of 12 to 18 months is designed to keep your SEM running smoothly, considering the specific usage and environmental conditions it operates under.

What is Included in a Regular PM?

Every regularly scheduled preventative maintenance aims to return the SEM to the original factory specification or better and includes the following:

- Inspection of the Column, Electron Source Emitter module, Backscatter Detector, objective lens, final aperture, and pole piece.

- Inspection & recalibration of Secondary Electron Detector

- Inspection & recalibration of Energy Dispersive X-Ray Spectroscopy Detector

- Inspection and cleaning of sample cup/tray and O-ring/gasket. Replace O-ring if necessary.

- Lubrication of the hardware, as needed.

- Pre-vacuum pump maintenance and rebuild

- Turbomolecular pump maintenance

- Inspection & adjustments, if necessary, of transports and SEM door

- Software and firmware upgrade to the most current version

The suggested 12 to 18-month service interval is a guideline that ensures the Phenom remains in peak condition, preventing any unforeseen downtime that could arise from overextended service intervals. While it’s understood that the electron source module is not a significant component of the preventative maintenance, the health of the pumps is paramount, and adhering to the advised maintenance schedule is a persuasive argument for safeguarding the intricate workings of this sophisticated equipment. It’s a small investment in time and care that yields significant returns in reliability and performance.

Common Questions Regarding PM

The internal turbomolecular pump and external pre-vacuum pumps are both essential to ensure uninterrupted operation of the Phenom SEM. These pumps operate continuously, around the clock, maintaining the vacuum environment in the column, regardless of whether the Phenom is being utilized for imaging. So, regular servicing, which includes cleaning, lubrication, and overall health checks, is not just a recommendation but a necessity to ensure continuous operation of these pumps.

In the maintenance of an SEM, the longevity of the source is not solely determined by operational hours. Factors such as image quality, oxidation of the CeB6 crystal, contamination, and electrical performance significantly influence the need for source replacement. Our engineers conduct thorough cleaning of the SEM and preventative maintenance before assessing the source’s condition. Only if the source fails to meet the manufacturer’s standards will it be considered for replacement, ensuring cost-effectiveness by avoiding unnecessary changes.

Service Maintenance Agreement (SMA)

The two-year SMA is a strategic investment that not only secures the necessary maintenance for your SEM but also offers substantial financial benefits. Our two-year SMA provides the necessary two PMs over the next 24 months at significant cost savings.

Enrolling the Phenom in the Nanoscience Instruments SMA program brings you additional benefits including significant discounts on repair, labor, parts, hardware upgrades, software add-ons, and Nanoscience Analytical services. Optionally, an electron source replacement can also be added to the SMA at a reduced cost. It also includes a private virtual training session valued at $500 and unlimited phone, email and remote web-based troubleshooting support.

- Depot Option: The SMA depot option provides a “easy hassle free” way to ship your instrument to our service depot for preventative maintenance. An optional shipping and handling protection during transit of the Phenom is also available.

- Onsite option: The SMA onsite option brings our engineering expertise directly to you, minimizing downtime and disruption to your workflow. Moreover, by opting to perform your PM and source replacement services onsite, you stand to save even more, with combined savings. This approach not only reduces downtime but also ensures that your SEM is maintained in its operational environment, which can be beneficial for its performance.

By choosing the Nanoscience Service Maintenance Agreement, you are prioritizing the care and performance of your class-leading Phenom SEM while also managing costs effectively. It’s an investment in the longevity and efficiency of your Phenom instrument, backed by the service of Nanoscience Instruments and the trusted quality of Thermo Fisher Scientific. Embrace this opportunity to enhance your experience and secure the best possible service for your technology.