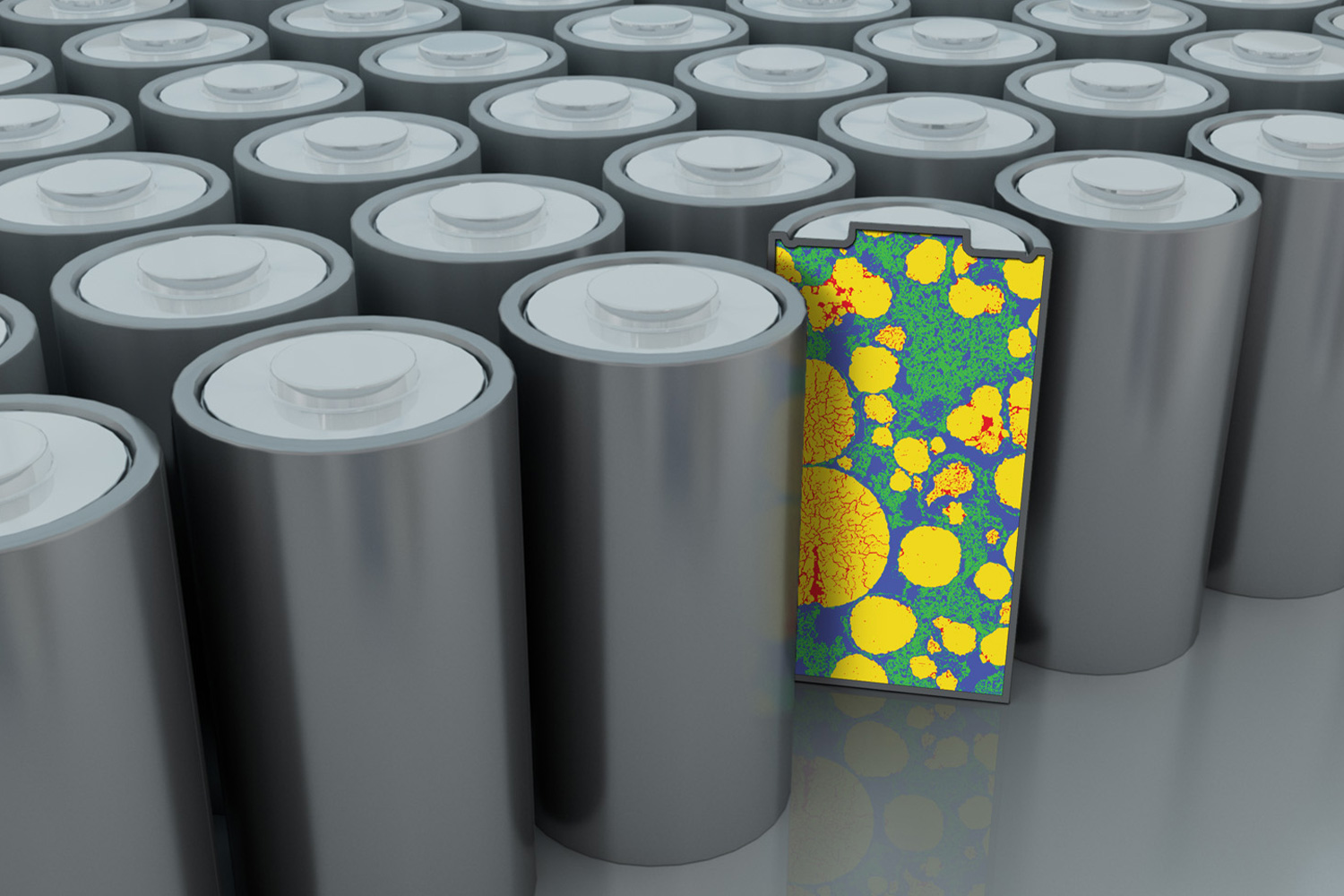

AUTOMATED BATTERY QA/QC SOLUTION

Avizo Trueput for Phenom SEM

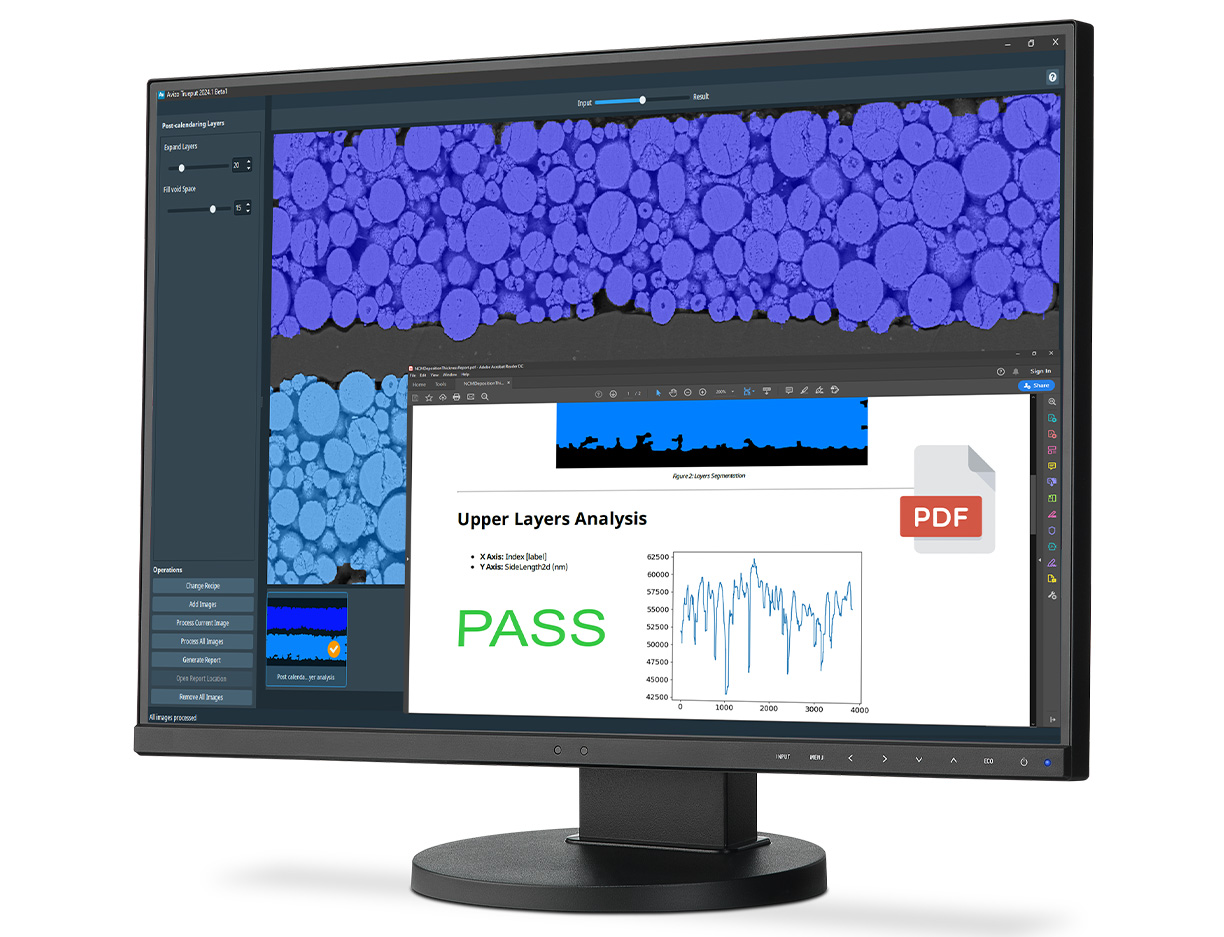

Transform your Phenom Desktop or Thermo Scientific SEM into a dedicated battery quality analysis solution with Avizo Trueput Software. Designed to streamline battery inspection on the production floor, Avizo Trueput automates image analysis, converting SEM image datasets into clear, reproducible pass/fail reports. This powerful tool enables QA/QC teams to maximize efficiency and maintain quality standards, freeing up valuable engineering time for more critical tasks.

Reproducible data interpretation

Standardize protocols across sites for reliable, consistent analysis.

Minimal operator intervention

Simplify workflows to reduce analysis costs and optimize engineering resources.

Unbiased pass/fail results

Generate clear, actionable outcomes with supporting data for confident decision-making.

Talk to an Instrumentation Specialist Today!

Turn Your SEM into a Specialized QA/QC Solution

Traditional methods for analyzing SEM data in battery quality applications often rely on non-standardized processes prone to variability and bias. Typically, operators capture images and relay their observations to quality engineers for further analysis, leading to inefficiencies and underutilization of available resources.

Avizo Trueput revolutionizes this process by providing operators with direct access to a growing library of standardized inspection protocols and pass/fail reporting. This ensures consistency across manufacturing sites, reduces operational costs per analysis, and unlocks the full potential of your SEM as a streamlined QA/QC solution.

Avizo Trueput

Software Features

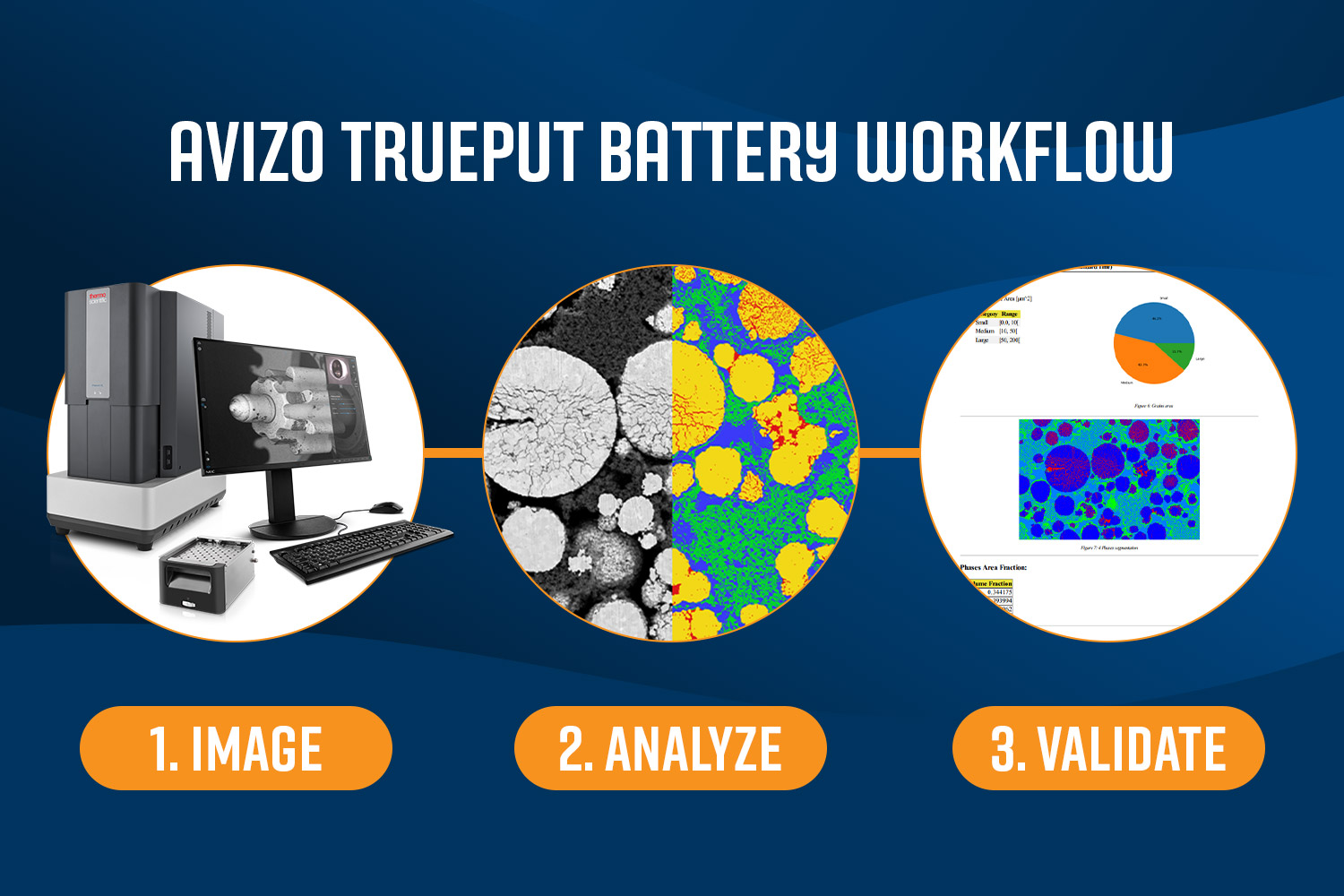

Growing catalog of automated inspection workflows

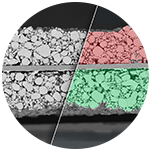

Choose from a growing library of workflows addressing battery manufacturing challenges like particle size distribution, cracked particles detection, and void/crack analysis.

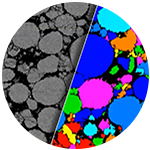

Particle Size Distribution |

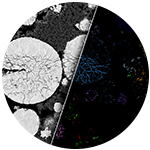

Cracked particles detection |

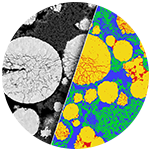

Particles/binder/void/cracks analysis |

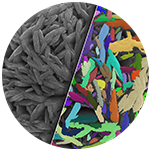

Precursor primary structure analysis |

Post-calendaring layers |

|

| Identified features: | Particles | Particles, cracks within particles | Particles, binder, void, cracks within particles | Primary particles in precursor | Layer of active material |

| Sample preparation: | Carbon tape or electrode surface | Carbon tape or electrode surface | Electrode surface | Carbon tape | Electrode surface |

| Reported information: | Particle size distribution compliance, packing factor | Number of cracked particles, cracks size analysis, compliance | Phases area fraction | Primary particles size distribution and orientation | Active material layer thickness |

| Where to use it: | Materials acceptance, tape manufacturing | Materials acceptance, after calendaring, after cycling | After calendaring, after cycling | Materials acceptance, prior to particles curing | After calendaring |

| Value for user: | Optimize cell energy density by achieving target packing factor | Optimize battery cyclability and reduce operational costs | Optimize battery cyclability and energy density | Optimizing curing operational costs | Optimizing energy density and calendaring operational costs |

Avizo Trueput

Product Knowledgebase

Using Automated SEM/EDS Analysis to Enhance Parts Cleanliness

Maintaining technical cleanliness is critical in industries where contamination can compro…

5 Benefits of Scanning Electron Microscopy for Particle Analysis

Particle analysis is a critical process in many industries, from pharmaceutical formulatio…

Automated SEM/EDS Monitoring of Steel Inclusions for Compliance with ASTM Standards

In modern steel manufacturing, non-metallic inclusions represent a critical quality concer…