Particle analysis is a critical process in many industries, from pharmaceutical formulation and nanomaterials development to forensic investigations and industrial manufacturing. Understanding the size, shape, and composition of particles plays a crucial role in ensuring product quality, optimizing performance, and meeting regulatory requirements.

Ensuring particle analysis is accurate, comprehensive, and free from human bias enhances the reliability of results, enabling faster and more confident data-driven decision-making. While traditional techniques like optical microscopy have been widely used for particle characterization, scanning electron microscopy (SEM) offers superior resolution, compositional analysis, and automation capabilities, making it an invaluable tool for modern particle analysis applications.

In this article, we’ll explore some of the common challenges in particle analysis and detail the key advantages of using SEM instead.

What are common challenges encountered in particle analysis?

While particle analysis may seem straightforward in theory, successfully integrating it into your organization or lab can present several challenges. These obstacles can affect the accuracy, efficiency, and reproducibility of results, making it essential to address them proactively. Here are some of the most common challenges:

- Time-consuming processes – Manual particle analysis methods can be slow, requiring significant time for sample preparation, imaging, and data interpretation.

- Minimizing human error in measurements – Manual measurements of particle size and shape introduce variability, leading to inconsistent results.

- Surveying enough particles for statistically significant conclusions – In some cases, analyzing too few particles can lead to misleading conclusions, while analyzing large datasets manually is impractical.

- Distinguishing between agglomerates and individual particles – In powders and suspensions, particles often cluster together, making it difficult to determine true particle size distributions.

- Measuring the right properties – Depending on the application, particle size, shape, texture, and composition all play critical roles, requiring a method that captures comprehensive data.

SEM overcomes many of these challenges by offering high-resolution imaging, automated data collection, and advanced compositional analysis, providing a more efficient, precise, and scalable approach to particle analysis.

What are the benefits of using SEM for particle analysis?

1. See Smaller Features Than with an Optical Microscope:

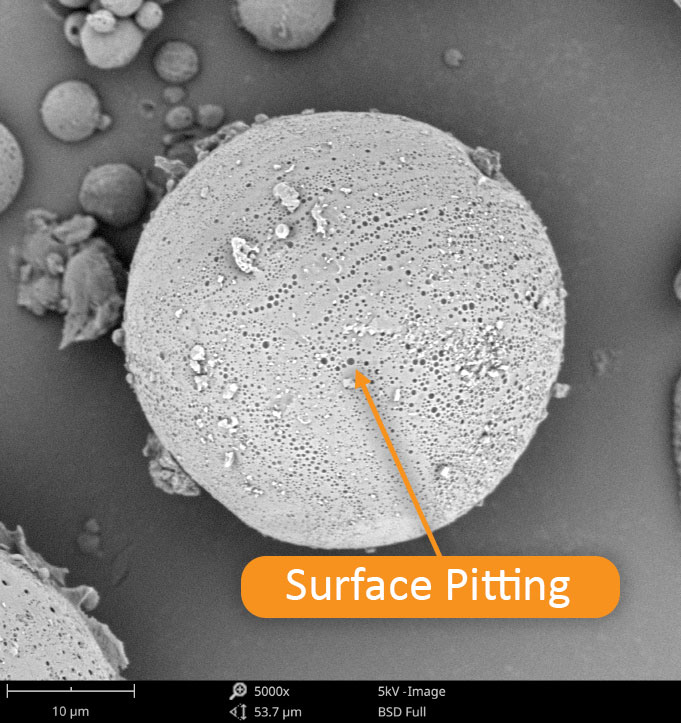

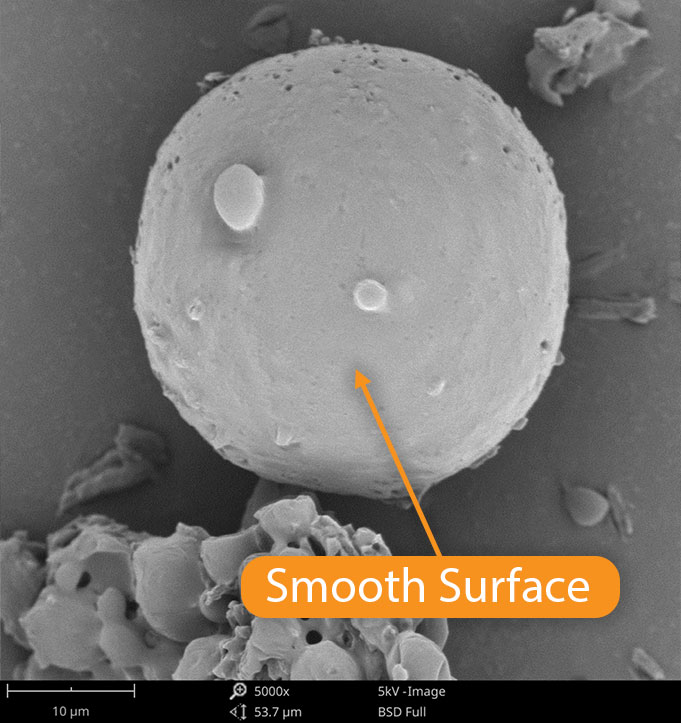

One of the most significant advantages of SEM is its ability to resolve features at the nanometer scale, far beyond the capabilities of an optical microscope. Optical microscopy is limited by the diffraction of light, which restricts its resolution to around 200 nanometers. In contrast, SEM uses an electron beam to achieve much higher resolution, enabling:

- Visualization of sub-micron and nanoscale particles

- Distinguishing nanoscale surface details that are invisible with optical methods, such as those seen in Figure 1.

- Distinguishing more clearly between individual particles and agglomerates

2. Get Chemical Information and Easily Connect It to Morphology

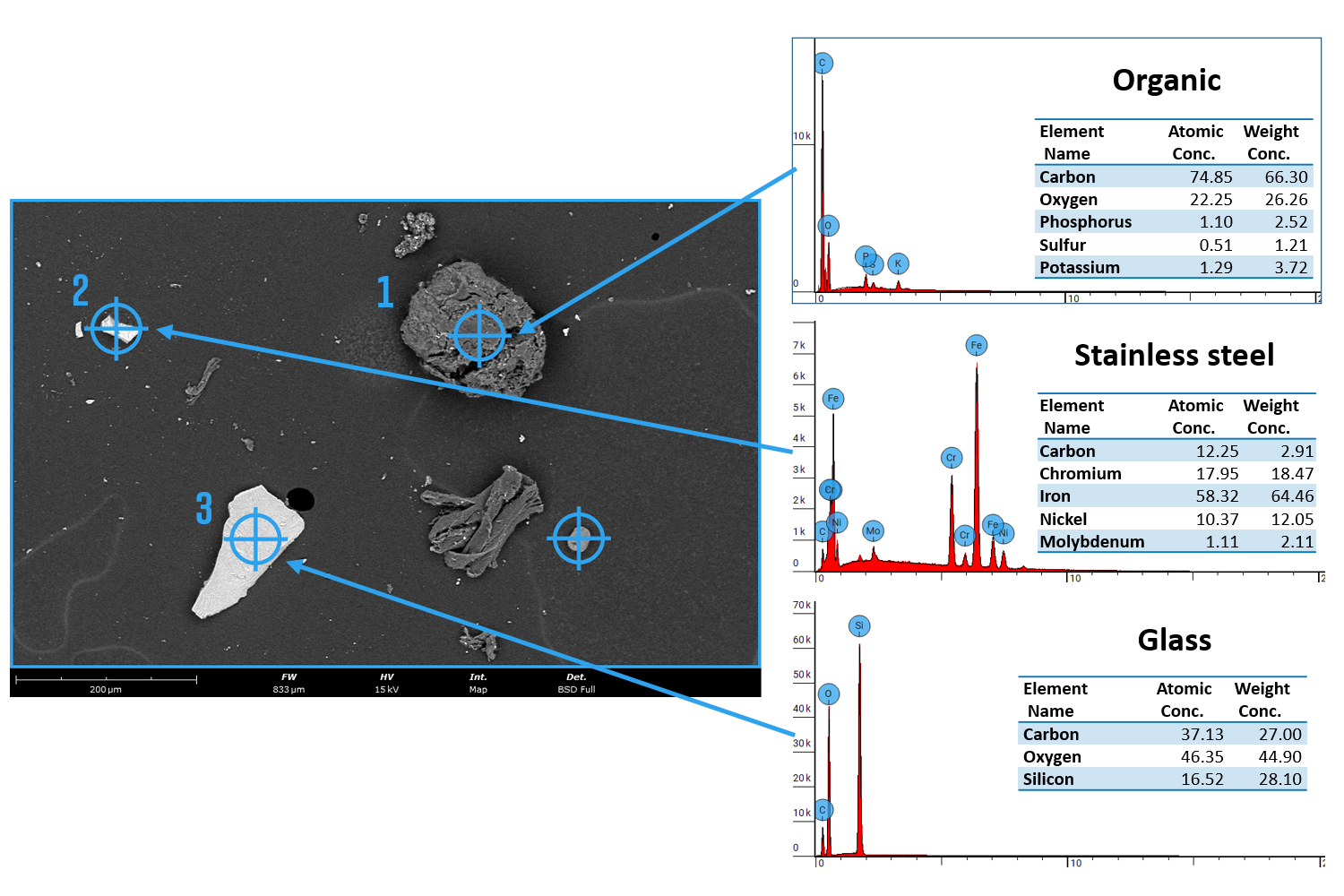

SEM is not only a powerful high-resolution imaging tool but also enables elemental analysis through energy dispersive X-ray spectroscopy (EDS). EDS works by detecting characteristic X-rays emitted from a sample when it is exposed to an electron beam. These X-ray signals are analyzed to generate a spectrum with distinct peaks corresponding to specific elements. The Phenom Desktop SEM’s EDS detector can identify a broad range of elements, from light elements like Boron (atomic number 5) to heavy elements such as Californium (atomic number 98). This allows for the detection of both organic materials and heavy metals using a single analytical technique.

SEM-EDS allows users to:

- Correlate particle size and morphology with chemistry in a single analysis

- Identify different material phases and distributions within heterogeneous particles

- Detect trace elements and identify “needle-in-a-haystack” contaminants that may impact product performance or safety

For example, quick point-and-shoot EDS analysis helps users confidently differentiate materials when SEM images alone are inconclusive. Figure 2 illustrates three EDS spectra collected from different particles within a single image. Particles 2 and 3 share sharp edges, bright contrast, and measure approximately 30 µm and 150 µm along their long axes, respectively. In contrast, Particle 1 appears darker with a rough, cracked surface and rounded edges. EDS analysis reveals that Particle 1 is primarily organic, while Particles 2 and 3 are compositionally distinct (despite visually sharing many characteristics). Particle 2 matches the elemental fingerprint of stainless steel, whereas Particle 3 is identified as glass.

3. Identify Foreign Material Quickly

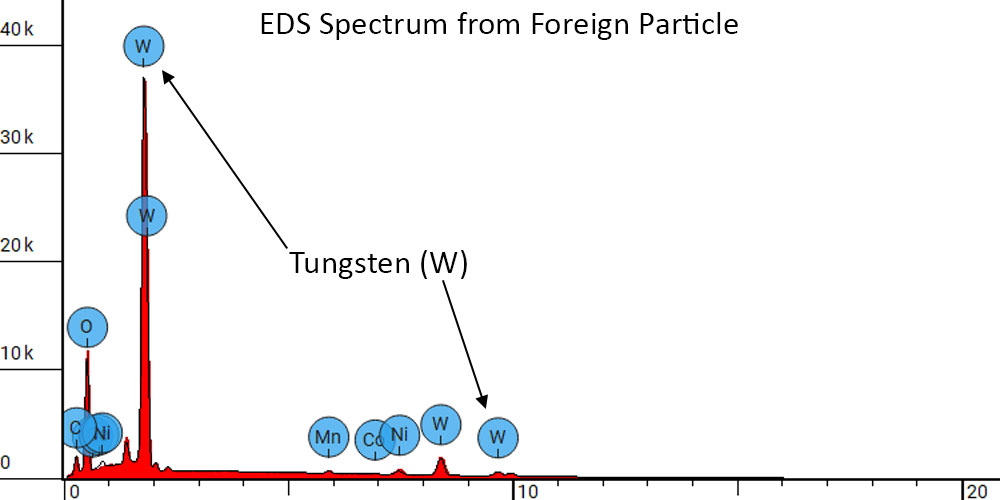

SEM imaging allows for rapid identification of foreign particles, while a quick point-and-shoot EDS analysis can confirm their composition within seconds. For example, Figure 3 shows an SEM image of a foreign particle observed in a cross-sectioned cathode tape. The bright contrast in the backscattered electron image suggests it may be a conductive metal particle, which could be detrimental to the battery’s functioning. The EDS spectrum confirms the presence of tungsten, which could have been introduced from tooling in the manufacturing flow or other causes.

Determining the elemental makeup of a contaminant is essential for pinpointing the root cause and implementing corrective measures to prevent future occurrences. The ability to rapidly identify unknown particles and contaminants is essential for:

- Failure analysis – Determining the cause of product defects or malfunctions

- Manufacturing quality control – Ensuring production environments remain free of unwanted materials

- Forensic investigations – Identifying unknown materials in criminal cases or environmental studies

Locating these so-called “killer particles” can be challenging with manual methods, as identifying contaminants often requires surveying a large number of particles. Optical microscopy, while useful, does not provide complete compositional analysis. In contrast, SEM combined with EDS offers a fast and reliable solution for detecting and characterizing contaminants, enabling organizations to address issues quickly and prevent costly defects.

4. Determine Particle Size Distributions While Taking Agglomeration into Account

Measuring particle size distributions is fundamental for quality control and materials characterization. SEM and optical microscopy can both measure particle size distributions, but SEM has distinct advantages that are becoming increasingly relevant as nanomaterials become more widespread across technologies.

One of these key advantages is that SEM can clearly distinguish between individual particles and agglomerates. It’s high-resolution imaging capability, paired with advanced particle analysis software, can provide quantitative information regarding particle shape and roundness, which when paired with particle size data and EDS analysis can reveal insights into degradation behavior or overall product quality.

SEM achieves this by:

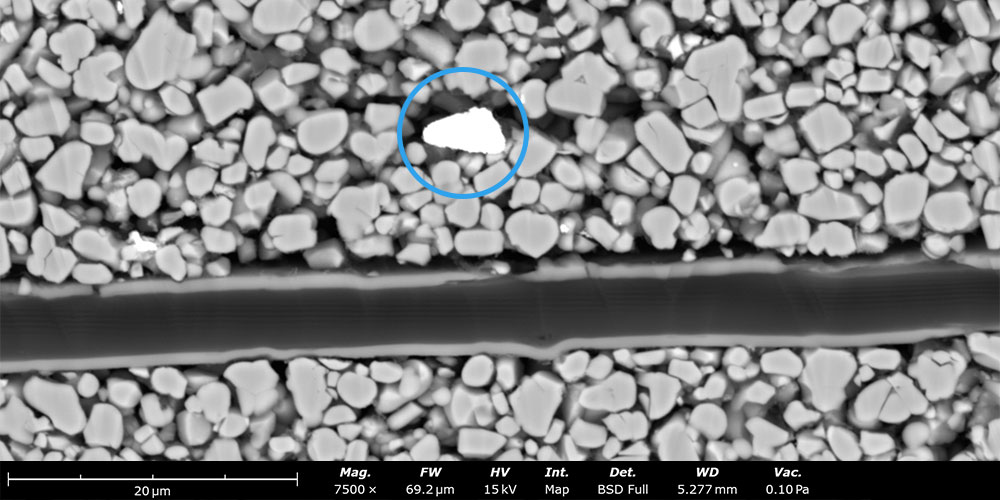

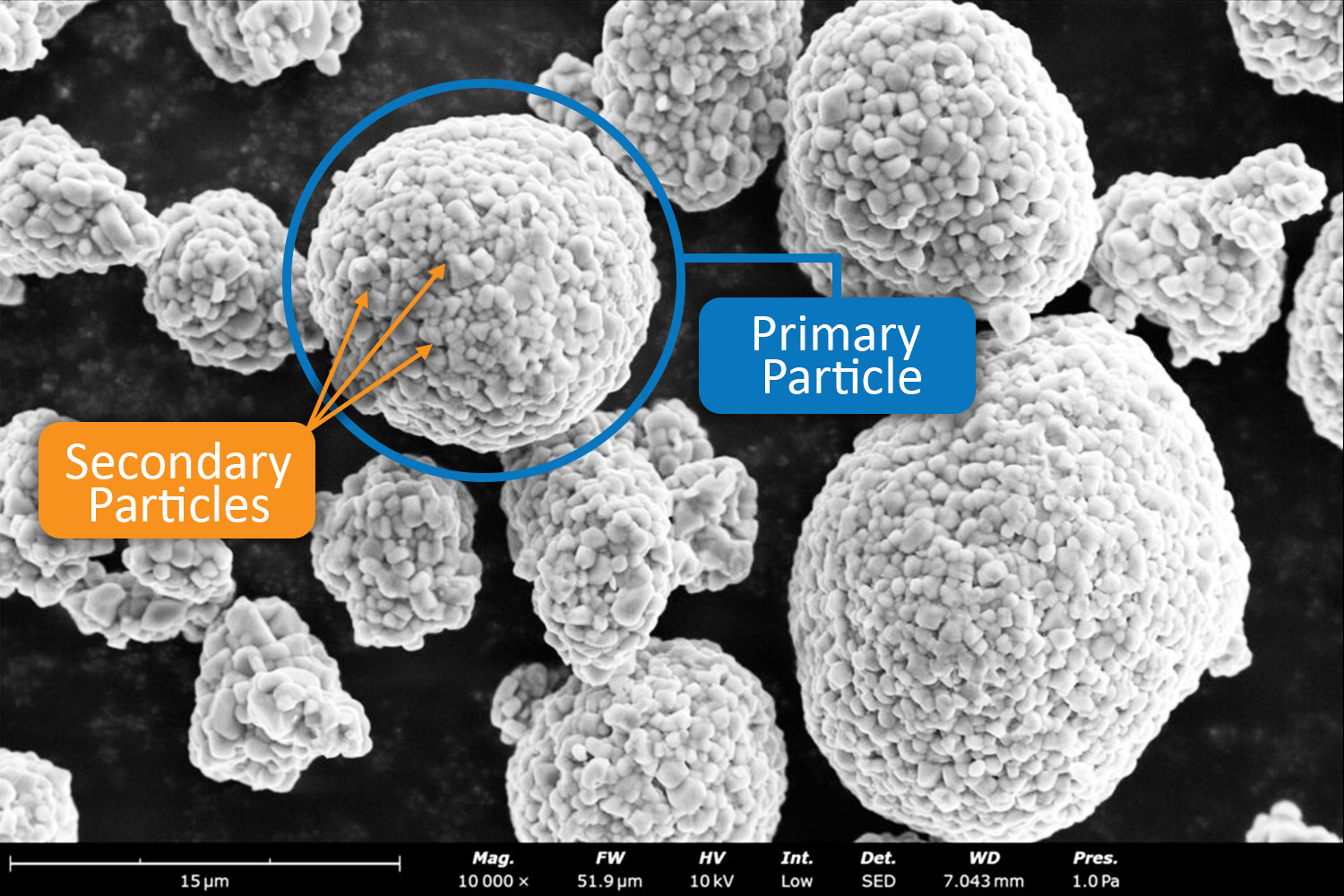

- Capturing high-resolution images that allow users to see whether particles are clustered or separate (Figure 4).

- Measuring shape characteristics such as circularity and aspect ratio.

- Providing elemental composition data, which can help reveal any trends between particle size/shape and composition.

For example, Figure 4 shows a SEM image acquired with a secondary electron detector (SED) of NCM particles, which are used in Li-ion battery assembly. The image shows that the primary particles, which are about 5 to 15 µm in size, are aggregates composed of sub-micrometer secondary particles.

5. Accelerate Data Collection and Analysis with Automation Software

Analyzing particles can often be slow, labor-intensive, and prone to human error. However, modern automated SEM software, such as Phenom ParticleX and ParticleMetric, streamlines this process by automating data collection, analysis, or both.

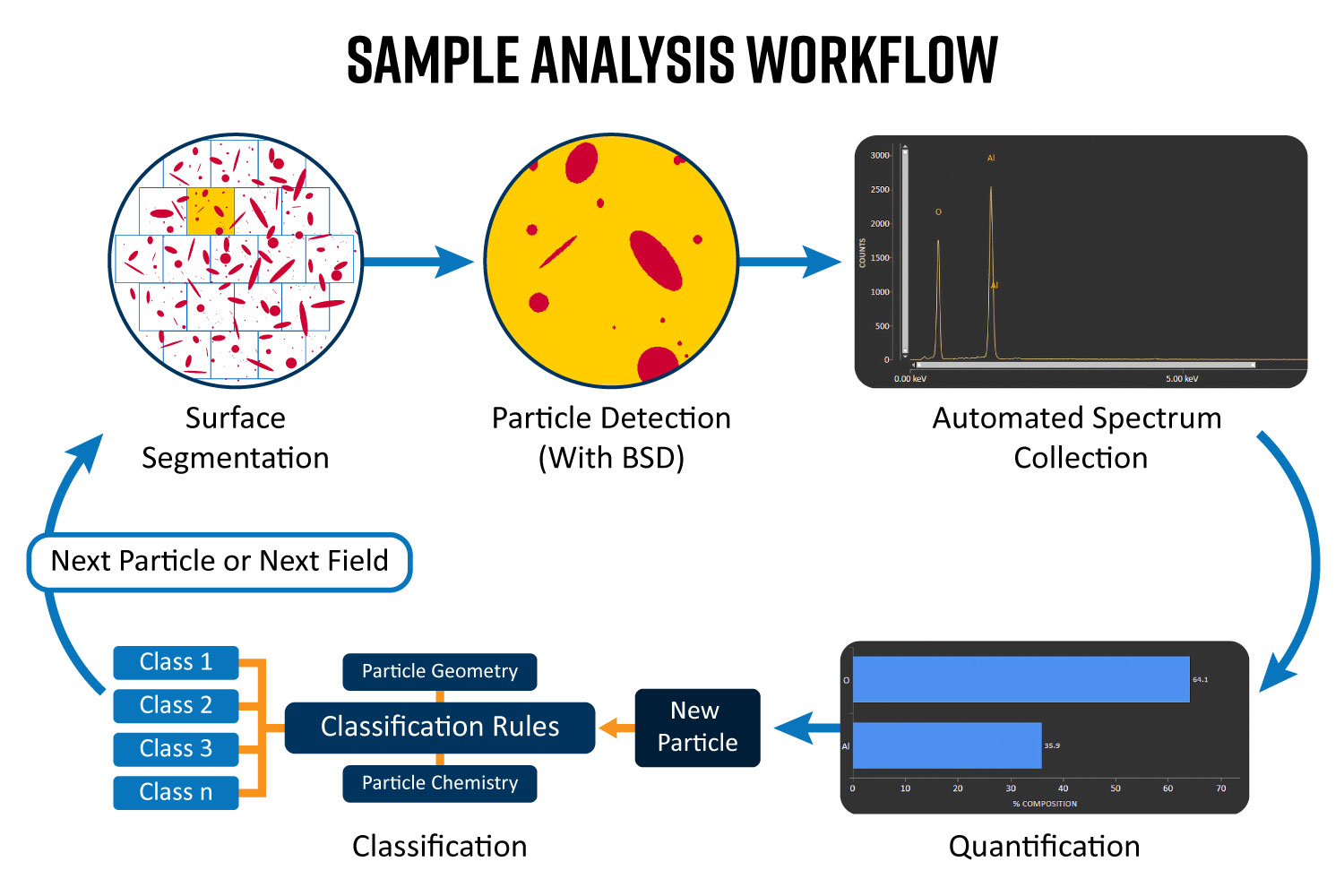

Phenom ParticleX automation software is designed exclusively for the Phenom XL Desktop SEM, which features a large sample stage capable of accommodating multiple smaller samples or larger specimens for automated tasks. Each ParticleX package is tailored to specific use cases, including technical cleanliness monitoring, battery materials characterization, gunshot residue analysis, and others. Fully integrated for seamless automation, ParticleX software enables data collection and analysis at the push of a button, as shown in the workflow in Figure 5, and offers the following benefits:

- Automatically detecting and classifying particles, reducing manual effort and user error

- Processing thousands of particles in minutes, improving statistical reliability while remaining cost effective

- Generating reports with actionable insights, enabling faster decision-making and standard-compliant processes

In contrast, ParticleMetric is compatible with all Phenom Desktop SEM models and focuses solely on automating SEM image analysis of particles. It provides size and shape measurements but does not integrate EDS results. This makes ParticleMetric an excellent choice for applications where composition analysis is unnecessary, such as cases where the material is well known, or contamination is not a primary concern.

Key Takeaways

By addressing common challenges and streamlining data collection, SEM provides a powerful, efficient, and precise solution for industries that rely on particle characterization. In summary, this article presents the five key benefits of using SEM for particle characterization which are:

- Unmatched resolution for seeing fine details

- Simultaneous chemical and morphological analysis

- Quick identification of contaminants

- Accurate particle size distribution measurements

- Automation for high-throughput analysis

If you’re looking to enhance your particle analysis workflow, or establish in-house particle analysis capabilities at your organization, contact us today to learn how Phenom Desktop SEM solutions can help.