Polymer compounding is a fundamental process in materials engineering that involves blending polymers with various additives to enhance their properties and performance. This allows manufacturers to tailor polymer materials to meet specific requirements for different industries including automotive, aerospace, healthcare and consumer goods. By tailoring the mechanical, thermal, and chemical properties of polymers, their range of applications can be significantly increased.

In this blog we delve into the basics of polymer compounding, its role in enhancing the properties of polymers and the application across a range of industries.

What is Polymer Compounding?

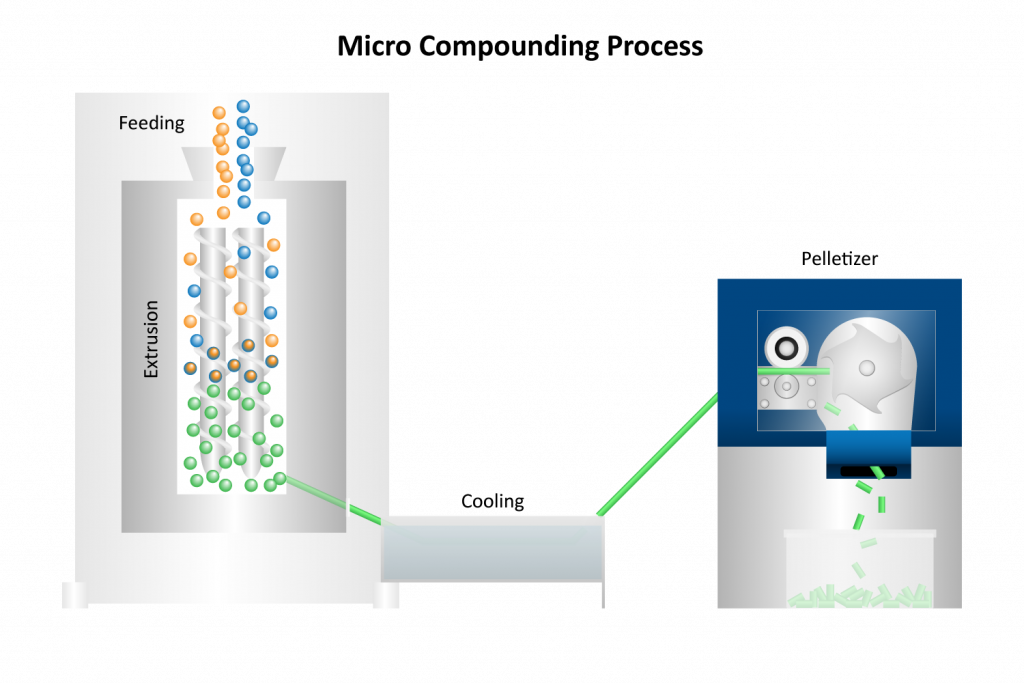

Polymer compounding is the process of mixing polymers with additives, fillers, and reinforcements to modify and improve a material’s desired physical and chemical characteristics1. By tailoring the polymer to encompass all the desired features in a single material, polymer compounding improves the quality of the final product, reduces cost, and improves productivity. It usually involves melting, blending, and extrusion to ensure a uniform dispersion of the components.

The most common additives used in polymer compounding include plasticizers to improve flexibility and reduce brittleness, stabilizers to enhance resistance to heat, UV light, and oxidation and flame retardants to reduce flammability and increase fire resistance. Other additives include colorants to improve aesthetics, fillers to reduce costs, reinforcements to improve mechanical strength and antimicrobial agents for medical and food science applications.

Applications of Polymer Compounding

Polymer compounding has been used in a variety of industries to develop customized materials that meet specific standards that are critical for industry. Some of the key industries where polymer compounding has made a significant impact include:

1. Automotive

The automotive industry has utilized polymer compounding to develop novel polymer compositions to replace metal components to reduce the weight of the vehicle and thereby improving fuel efficiency, without sacrificing key safety features.2 Some of the key developments include using reinforced thermoplastics for bumpers and body panels that are lighter than steel but provide similar impact resistance and durability. High-performance polymers that can withstand heat, oil, and mechanical stress have been developed and used as engine covers, tubing, and connectors. Rubber-based compounds that enhance tire grip, longevity, and weather resistance are used for making tires and seals. Compounded polymers that enhance the aesthetics and comfort have been used for interior components such as dashboards, seats, and trims.

2. Aerospace and Defense

The aerospace industry has developed lightweight, high-strength polymer composites that improve fuel efficiency and structural integrity.3 Few of the examples include the use of carbon fiber-reinforced polymers (CFRPs) as structural components in aircraft fuselage and wings since they provide excellent strength-to-weight ratios. Specialized polymer compounds have been used for thermal and acoustic insulation for their ability to reduce noise and maintain cabin temperature. Fire-retardant polymers have been utilized to enhance passenger safety. Radar absorbing polymer composites have found applications in the air defense industry in the development of stealth aircraft.

3. Healthcare

The healthcare industry relies on polymer compounding for biocompatible and sterilizable materials used in devices, packaging, and prosthetics. Some notable applications include the use of flexible, non-toxic polymers with antimicrobial properties for medical tubing and catheters, heat-resistant and durable polymers that provide precision and sterility for surgical instruments and barrier-resistant polymer films to protect medications from moisture and contamination in pharmaceutical packaging. High-strength, lightweight polymer compounds have also been used in prosthetics and implants to improve comfort and durability.

4. Electronics and Electrical Industry

The electronics industry depends on polymer compounds to improve insulation, conductivity, and durability. A few key applications include using flame-retardant and flexible polymers for wire and cable insulation, conductive polymers in flexible displays, sensors, and energy storage devices and polymer laminates in printed circuit boards (PCBs) to provide structural integrity and electrical insulation. Polymer composites have also been used in encapsulation and coatings to protect sensitive electronic components from moisture, heat, and mechanical damage.

5. Construction

The construction industry benefits from polymer compounds due to their durability, weather resistance, and sustainability4. PVC (poly (vinyl chloride)) and PE (Polyethylene) compounds have been used extensively in pipes and fittings due to their corrosion resistance and longevity. Reinforced polymer panels are used in bridges and buildings for lightweight and high-strength applications. Foam-based polymers, due to their thermal and acoustic insulation properties, are used in roofing and insulation. Polymer-based materials are used as floor and wall covering since they are durable, easy to clean, and aesthetically versatile.

6. Consumer Goods and Packaging

Polymer compounding enhances everyday products by improving their functionality, durability, and aesthetics. A few examples of everyday products include the use of lightweight, impact-resistant polymer compounds in sports equipment to enhance performance, durable plastics with UV and chemical resistance in household products and non-toxic, BPA-free polymer compounds to ensure child safety in toys and baby products. Polymer composites have also been used as barrier films and antimicrobial polymers in food packaging to extend shelf life and improve food safety.

Future Trends in Polymer Compounding

The polymer compounding industry is evolving rapidly, driven by advancements in material science, sustainability goals, and the demand for high-performance applications. Increasing environmental concerns have resulted in the polymer industry shifting towards biodegradable and bio-based polymers. The use of natural fibers as renewable fillers is gaining popularity. Nanomaterials, such as graphene and carbon nanotubes, are increasingly incorporated into polymer matrices to enhance mechanical, thermal, and electrical properties. These advancements are particularly significant for applications in aerospace, automotive, and electronics.

The development of smart polymers with self-healing, shape-memory, and conductivity-enhancing properties is opening new possibilities in healthcare, wearable technology, and advanced manufacturing. The use of AI and machine learning in compounding process optimization is also emerging to improve efficiency and consistency.

Conclusion

Polymer compounding is a transformative process that enables the development of customized polymer materials for a wide range of applications. By enhancing mechanical, thermal, and chemical properties, compounded polymers play a crucial role in industries such as automotive, aerospace, healthcare, electronics, construction, and consumer goods.

The future of polymer compounding is centered around sustainability, high-performance materials, and technological advancements. As industries push for greener solutions and enhanced material capabilities, polymer compounding will remain at the forefront of innovation, driving sustainability and performance improvements across multiple sectors.

References

- Kohlgrüber, K., Bierdel, M., & Rust, H. (2021). Plastics Compounding and polymer processing: fundamentals, machines, equipment, application technology. Carl Hanser Verlag GmbH Co KG. ↩︎

- Shah, V., Bhaliya, J., Patel, G. M., & Deshmukh, K. (2022). Advances in polymeric nanocomposites for automotive applications: A review. Polymers for Advanced Technologies, 33(10), 3023-3048. https://doi.org/10.1002/pat.5771 ↩︎

- Dyer, W. E., & Kumru, B. (2023). Polymers as aerospace structural components: how to reach sustainability? Macromolecular Chemistry and Physics, 224(24), 2300186. https://doi.org/10.1002/macp.202300186 ↩︎

- Shen, J., Liang, J., Lin, X., Lin, H., Yu, J., & Wang, S. (2022). The Flame-Retardant Mechanisms and Preparation of Polymer Composites and Their Potential Application in Construction Engineering. Polymers, 14(1), 82. https://doi.org/10.3390/polym14010082 ↩︎