Fiber-based filtration systems clean everything from the air we breathe to the oil that runs our engines. Many filters, like high-efficiency particulate air (HEPA) and ultra-low particulate air (ULPA) filters, are made from glass or polymer fibers. Some are a woven mesh of metal fibers, while others are manufactured from nonwoven media. Some filters even use a thin layer of nanofibers to increase performance and efficiency. Filter shapes, sizes, and compositions vary widely depending upon the application. Efficient and effective filters are important in homes, businesses, and manufacturing environments.

This application note will discuss the advantages of scanning electron microscopy (SEM) over optical microscopy for analyzing fiber-based filters. Scanning Electron Microscopy provides high-resolution images, elemental analysis, and – thanks to the FiberMetric software on the Phenom SEM – the ability to automatically measure thousands of fibers in mere minutes.

Advantages of SEM for Evaluating Filtration Fibers & Membranes

Advanced microscopy techniques are crucial for filter performance evaluation. While optical inspection has been the industry standard for the past several decades, it has become insufficient for new applications. Fiber dimensions, especially nanofibers, often fall below the resolution limit of an optical microscope.

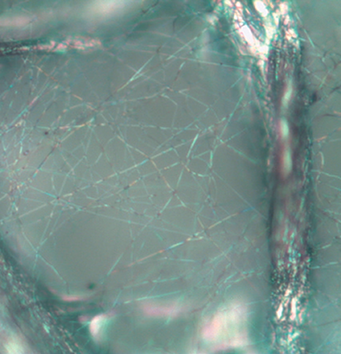

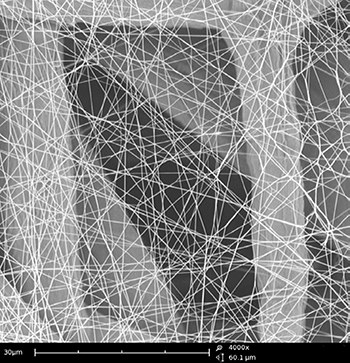

With its higher resolution and depth of field, the scanning electron microscope (SEM) is the new standard tool for filtration material characterization. Image comparison of the same area of a nanofiber membrane using an optical microscope (left) and an SEM (right) reveals the vast difference in resolution and contrast between the two techniques.

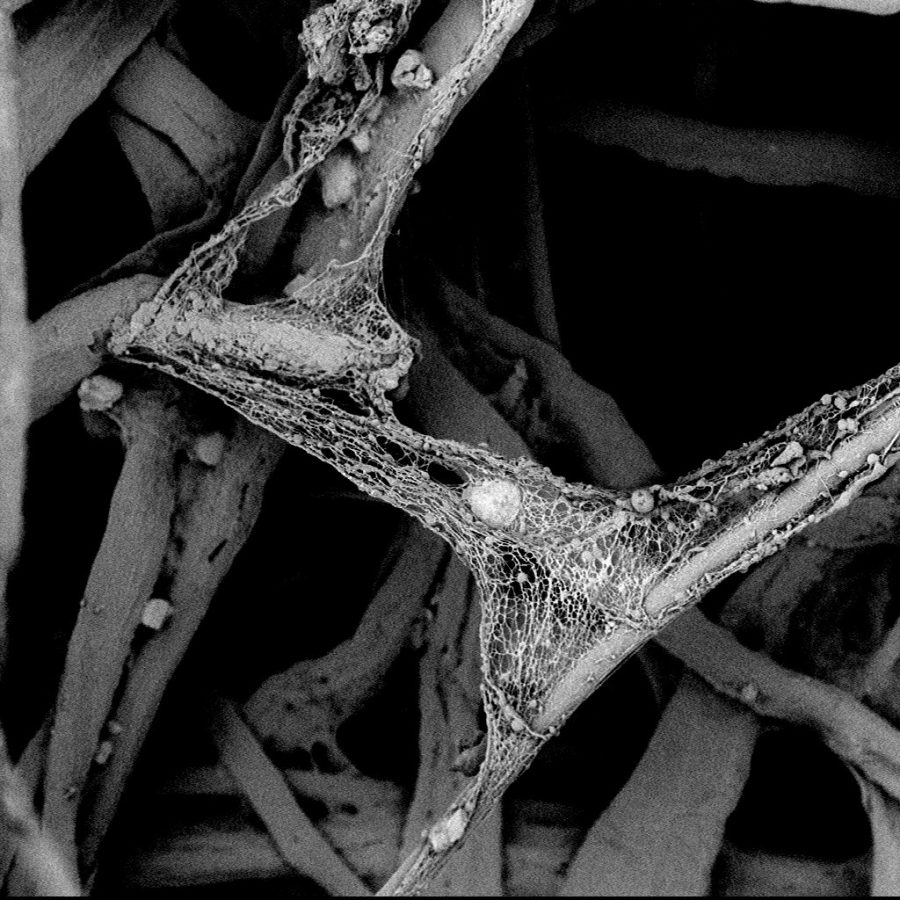

These images show SEM micrographs of a nonwoven nanofiber membrane attached to the surface of a filter. Nanofiber membranes are often attached to air filtration media to maximize filter efficiency, airflow and lifetime. This filter did not pass testing because the nanofiber membrane was not complete. At some point during processing or transport, the nanofiber membrane detached, leaving exposed areas. The holes in the nanofiber membrane led to a decrease in performance for this filter.

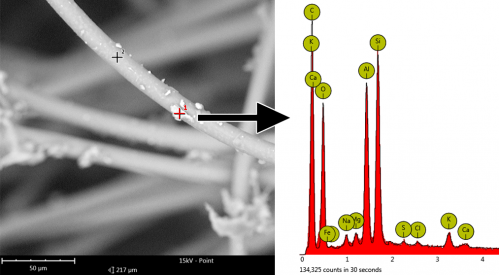

Elemental Analysis for Foreign Particulates in Filtration

The contaminants captured by a filter can be identified using energy dispersive X-ray spectroscopy (EDS). The SEM integrated this technique and can give the elemental composition of a sample during imaging.

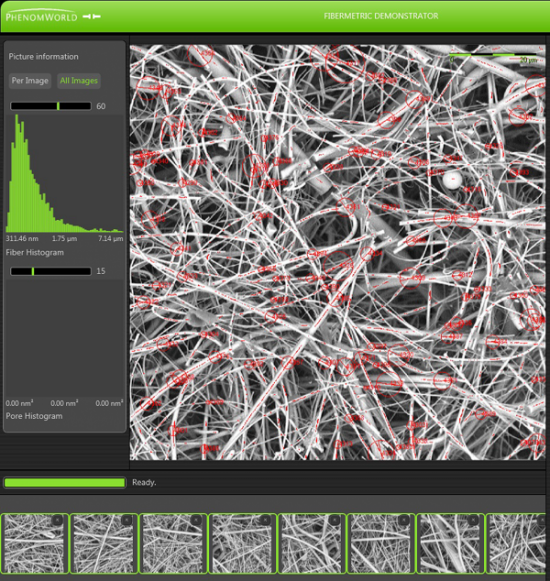

Automated Fiber Characterization

The Phenom SEM is designed to bring high-quality SEM imaging into environments where a traditional SEM was not manageable or practical. The Phenom SEM:

- Is accessible and intuitive to use

- Produces superior images

- Provides high productivity and workflow

The Phenom SEM does not require a dedicated operator or additional infrastructure. The innovative column design allows imaging of fibers without sputter coating.

The Phenom desktop SEM uses FiberMetric, a proprietary fiber measurement software package, which measures fiber diameter, orientation and pore sizes. Using the integrated motorized XY stage, data acquisition and analysis can easily be automated. This combination of software and hardware allows for hundreds of images to be acquired automatically, resulting in tens of thousands of individual fiber measurements, providing statistically significant data.