Introduction

Surface and interfacial tensions of liquids significantly affect their wetting behavior and interactions with other substances. These forces influence how liquids spread on solid surfaces, which are critical to coating processes like bonding, painting, and printing. In other industrial processes, like the production of food, cosmetics, pharmaceuticals, and agrochemicals, the surface and interfacial tensions can govern product stability when forming foams and emulsions. Surface tension also plays a key role in the effectiveness of cleaning agents.

Optical and force tensiometry are both techniques used to measure surface and interfacial tensions. While these two techniques measure similar properties, they have key differences and unique strengths for certain applications.

What is Optical Tensiometry?

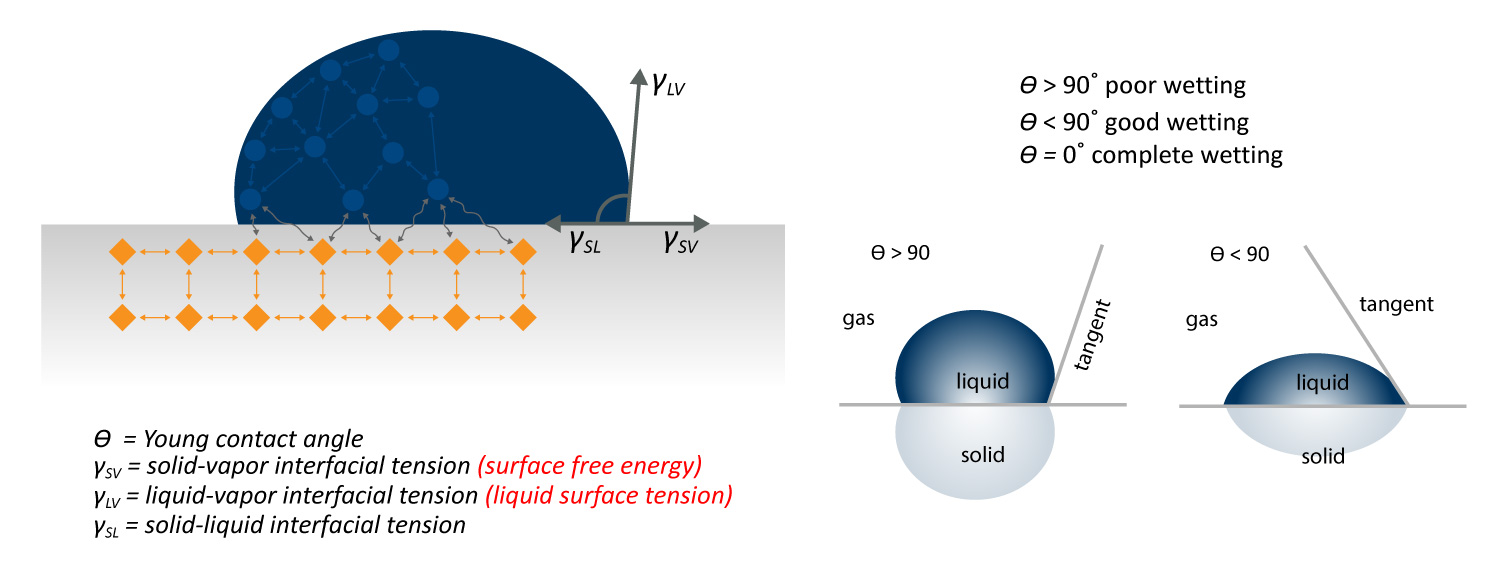

Optical tensiometry, also referred to as contact angle goniometry, is a technique used to measure the contact angle of a liquid drop on a solid surface (Figure 1). It enables the characterization of surface properties such as wettability and adhesion. Typical optical tensiometers consist of a liquid dispenser to dispense a defined volume of liquid and a light source to illuminate the drop. Images of a liquid drop placed on a solid surface (sessile drop method), suspended from a needle or pipette tip (pendant drop method) or a bubble trapped underneath the liquid surface (captive bubble method) are captured with a digital camera. Drop shape analysis is used to determine interfacial properties such as contact angle and surface tension. Optical tensiometry is a fast and versatile method that can also carry out dynamic measurements for studying changes over time. It requires optical clarity and good lighting to capture images.

What is Force Tensiometry?

Force tensiometry is a technique generally used to measure surface and interfacial tension of liquids, although it can also be used to measure other properties like density, critical micelle concentration, powder wettability, and more (Figure 2). In force tensiometry, unlike optical tensiometry, an analytical balance measures force exerted on a specialized probe as it interacts with a liquid-gas or liquid-liquid interface. Typical force tensiometers have an electrobalance to which a probe is attached. Force tensiometry can be used with transparent, opaque, colored, or even foamy liquids. Since the measurement probe is directly in contact with the liquid, it requires careful cleaning and calibration to prevent contamination.

How to Measure Surface Tension?

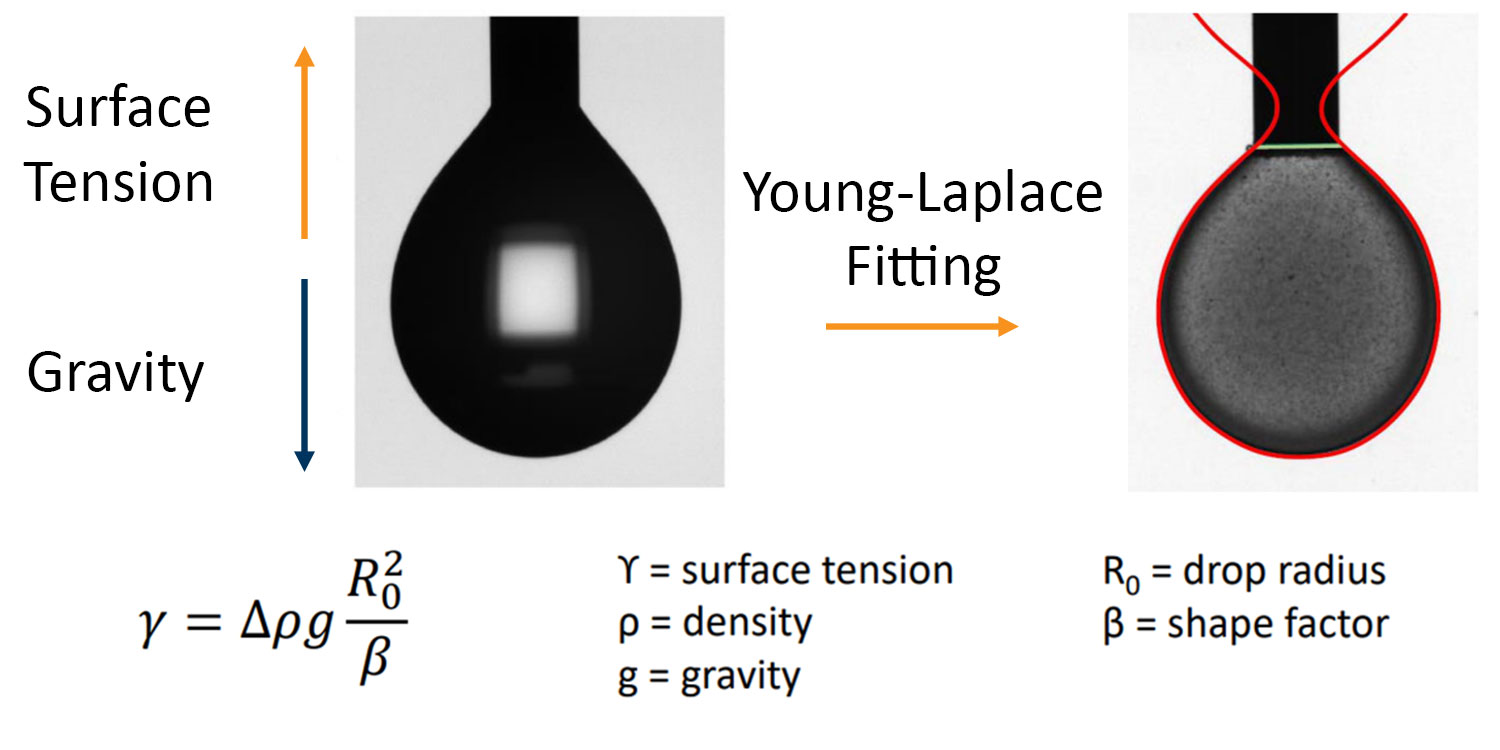

The pendant drop method is used to measure surface tension with optical tensiometry (Figure 3). In a pendant drop experiment, a small drop of liquid is dispensed and suspended at the end of a needle or pipette tip to form a tear-shaped pendant drop. The drop shape in the optical image is fitted with a model, usually based on the Young-Laplace equation, to determine surface tension. This method can also determine the interfacial tension of two immiscible liquids by immersing the pendant drop in another liquid contained in a cuvette. The liquid contained in the cuvette must be optically transparent to properly capture the pendant drop image with the camera. One caveat with this method is that the density of the liquid(s) must be known to calculate the surface or interfacial tension.

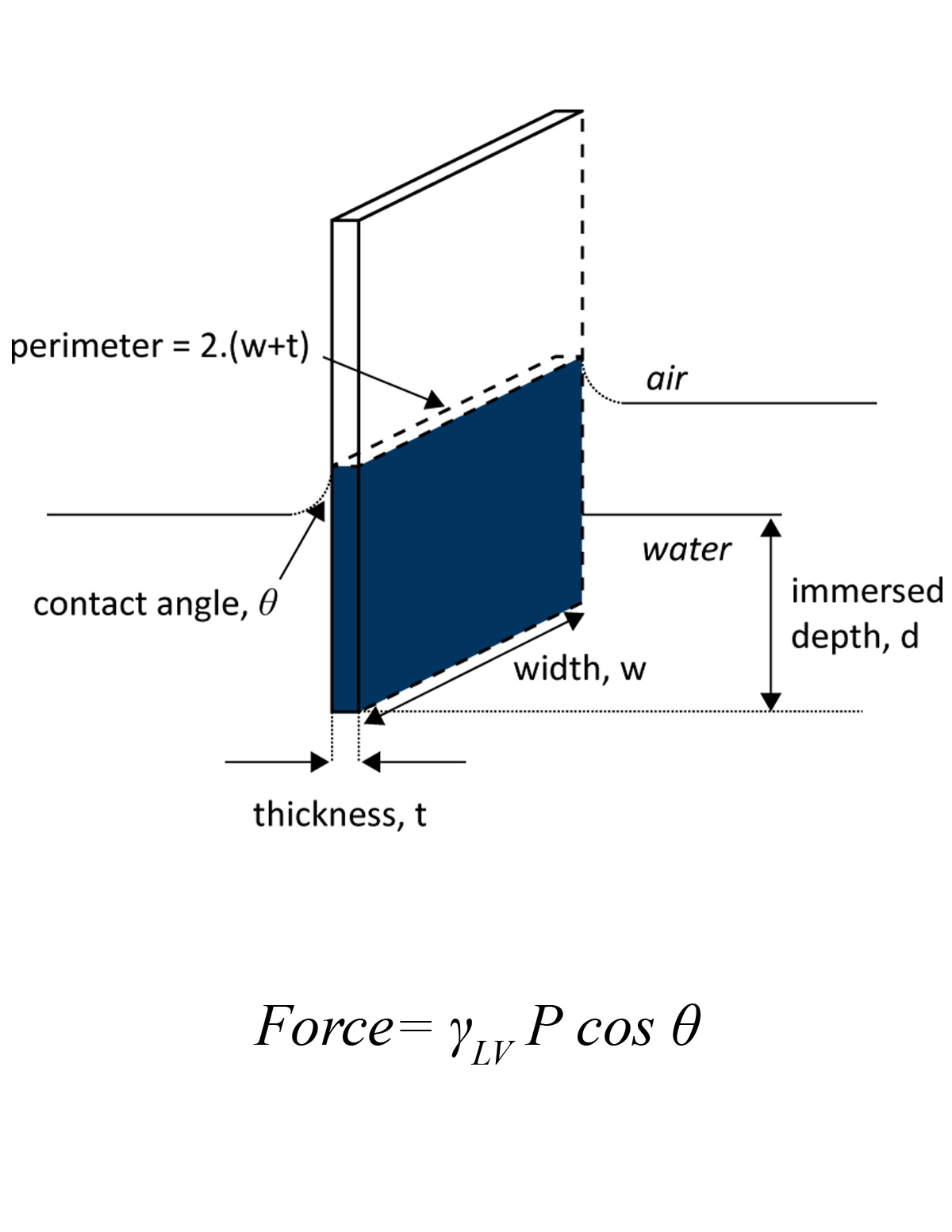

Surface tension and interfacial tension can be measured with force tensiometry using one of two different methods: the Wilhelmy plate method or the du Noüy ring method. In a Wilhelmy plate measurement, a thin platinum plate with known geometry is immersed to a set depth below the liquid-gas interface. The plate is then returned to the liquid-gas interface (the zero depth of immersion), and the force is recorded. This force can be recorded at discrete points or continuously as the plate remains stationary. Surface tension is determined from the measured force with the equation (Figure 9):

Wetting force = γL Pcosθ

Where γL is the liquid’s surface tension, P is the wetted perimeter of the plate (a known value), and θ is the contact angle between the plate and the liquid (assumed to be zero for a clean platinum Wilhelmy plate). This measurement can also be done at the liquid-liquid interface to determine interfacial tension. However, a compensation factor is needed to account for buoyancy from the less dense liquid.

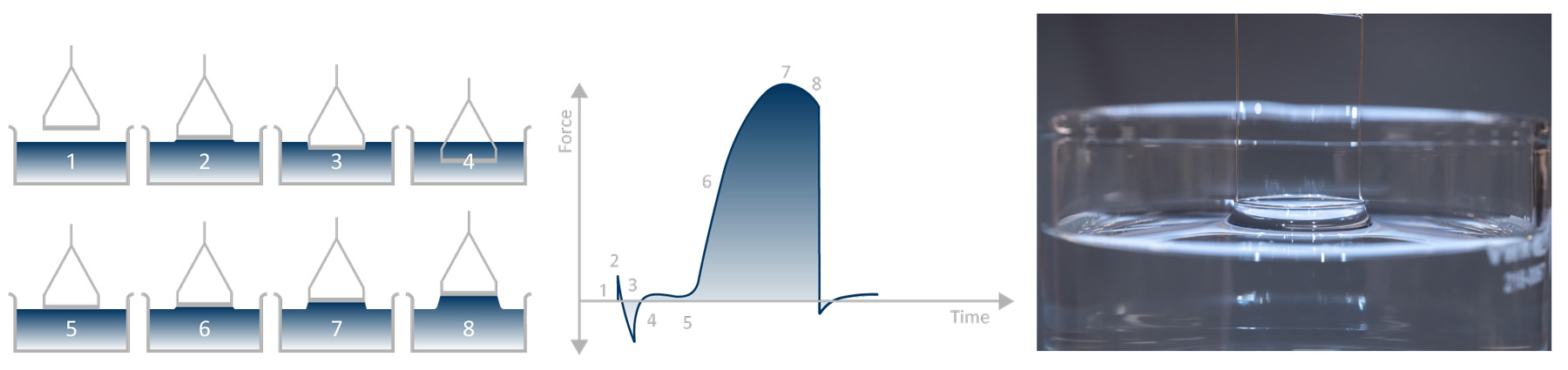

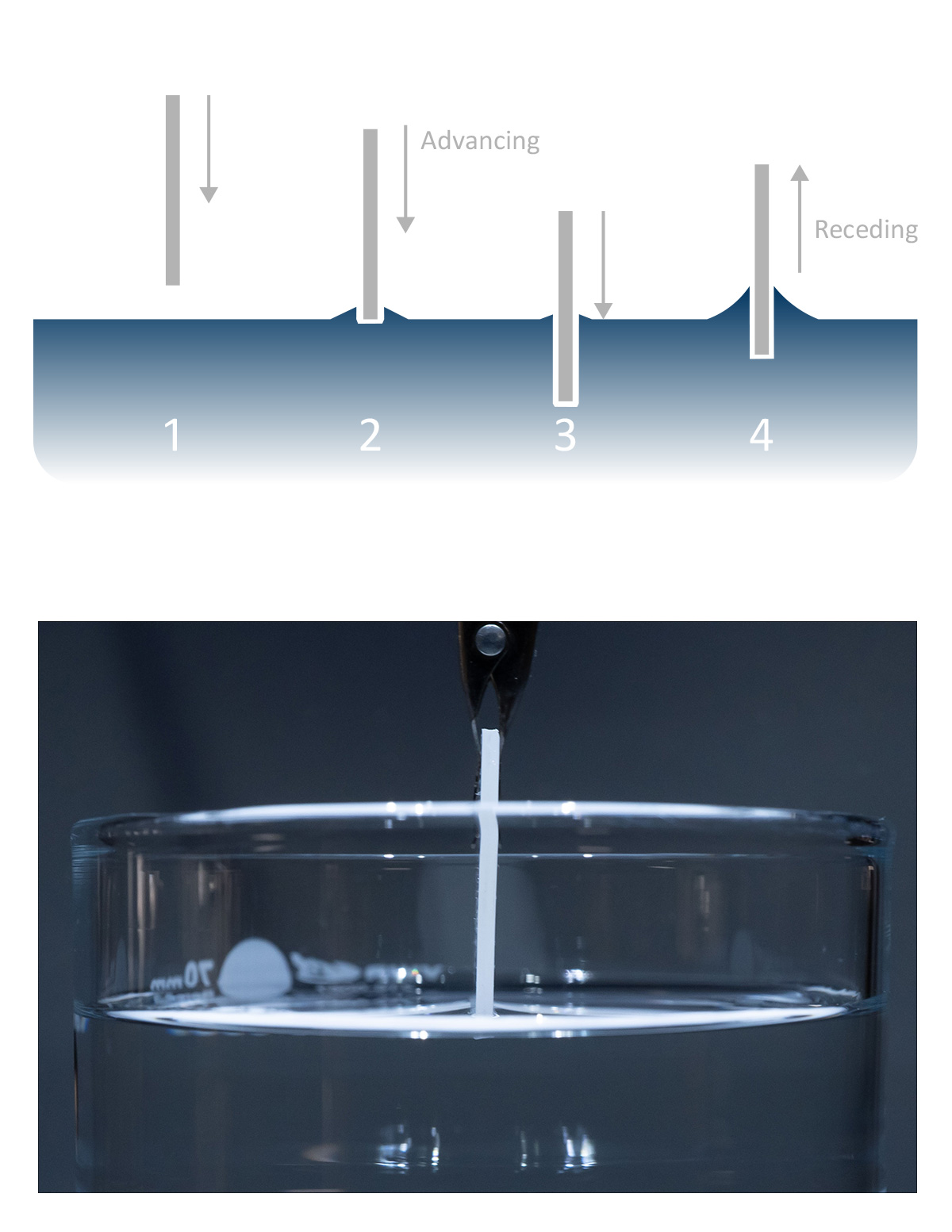

In a du Noüy ring measurement, a platinum ring with known geometry is submerged beneath the liquid-gas or liquid-liquid interface and then pulled through the interface, bringing with it a meniscus of liquid (Figure 4). As the ring is pulled further from the interface, the force reaches a maximum value and then begins to drop just before the meniscus tears. This maximum force value is used to calculate surface tension and interfacial tension. Because original du Noüy ring calculations were based on a ring of infinite diameter and a wire of zero thickness, a correction factor is needed to determine the true surface and interfacial tension. Modern force tensiometers can apply these correction factors automatically provided that the density of the liquid(s) is known.

How to Measure Contact Angle?

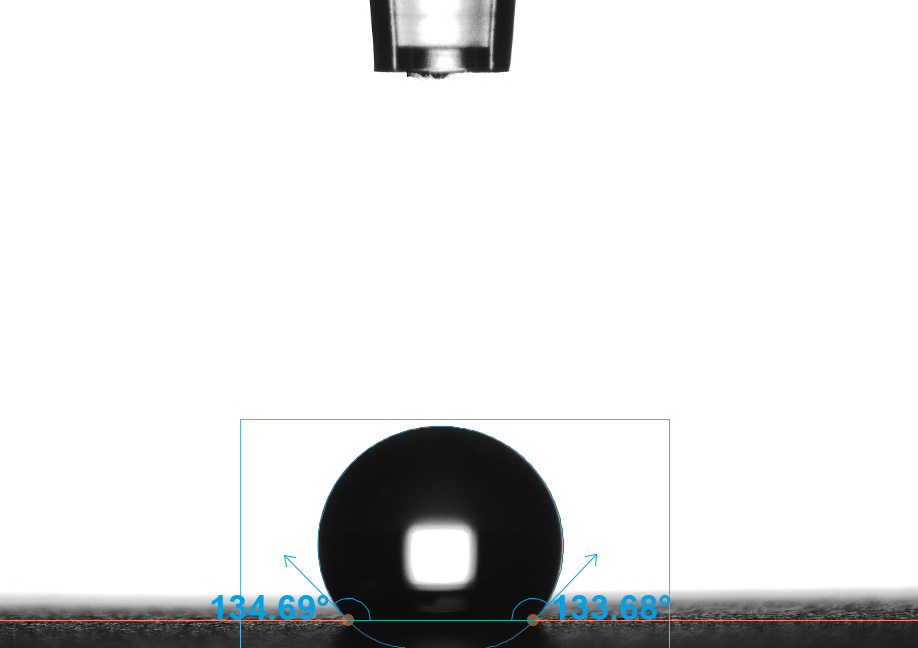

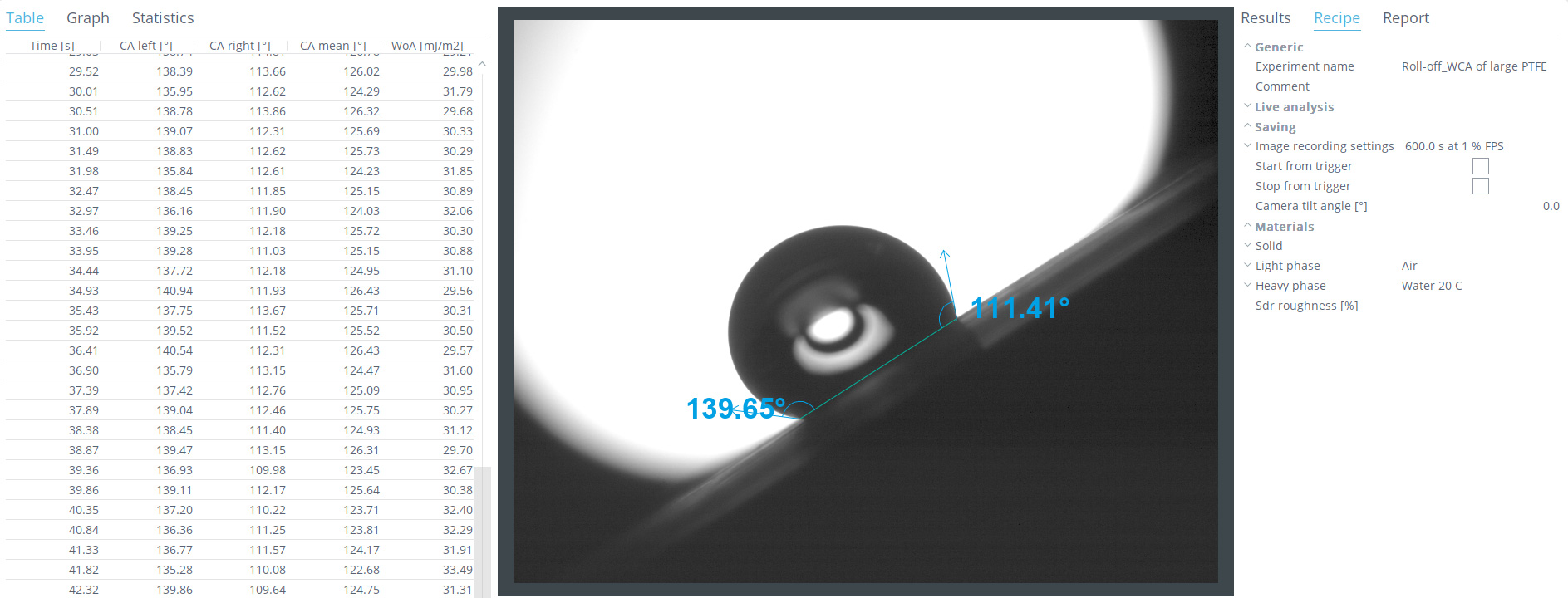

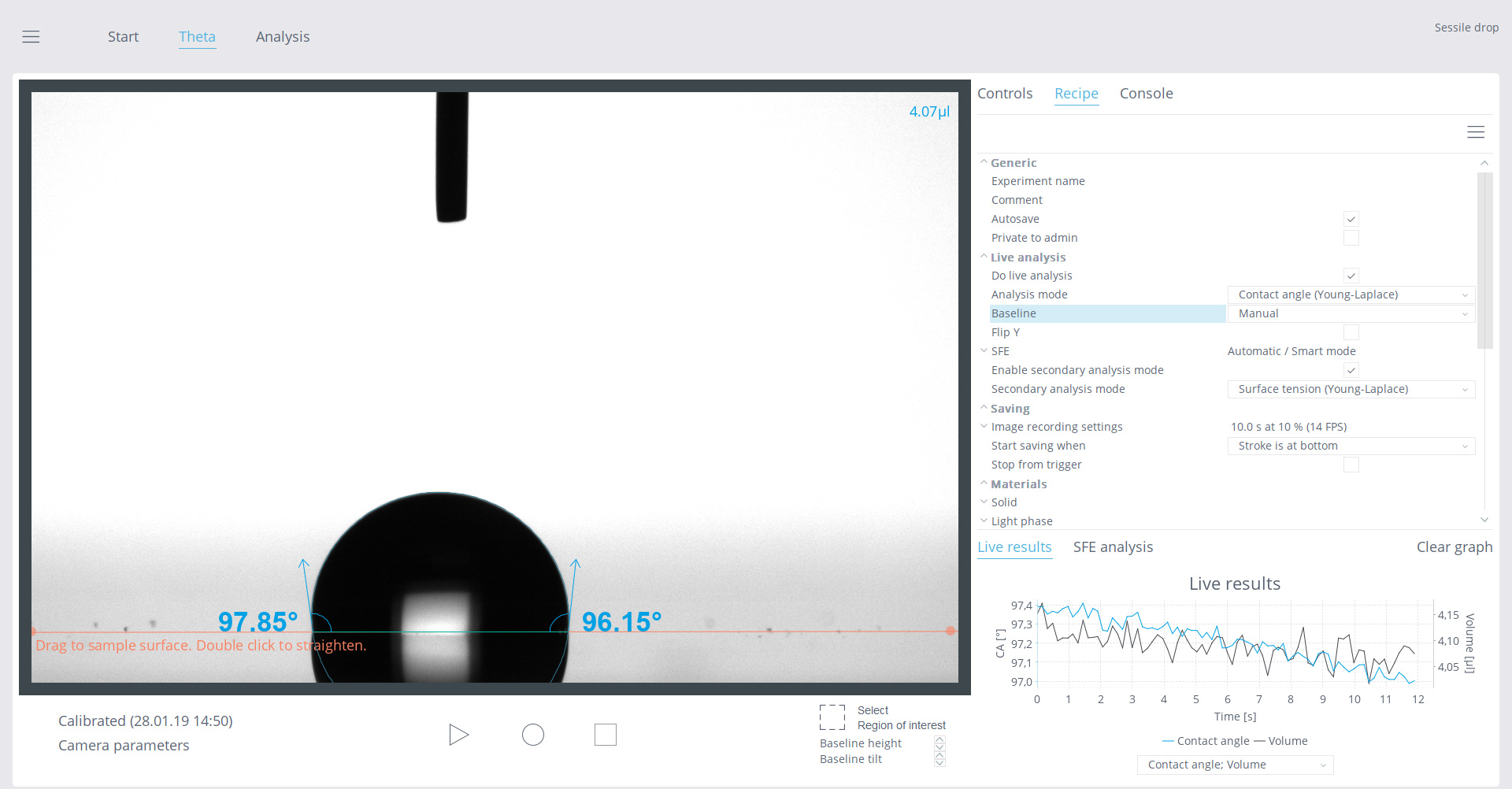

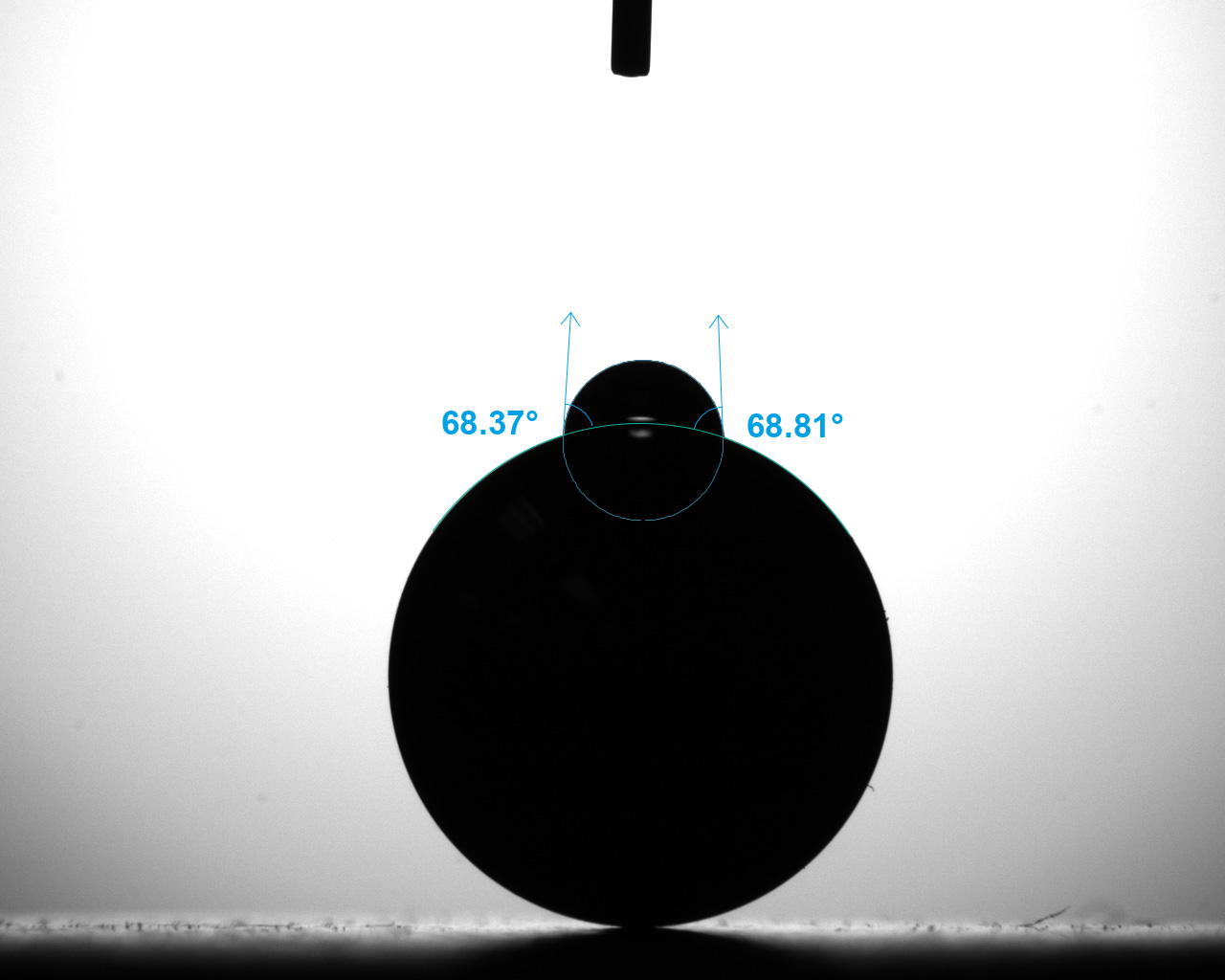

The simplest way to measure contact angle with an optical tensiometer is with the sessile drop method: a liquid droplet is placed on a solid surface and the resulting angle formed between the solid and the tangent to the drop surface is measured (Figure 5). A high-resolution camera is used to take an image of the drop and software is used to fit the drop image with a model to measure the contact angle (Figure 7). Optical tensiometers can also measure contact angle under dynamic conditions, such as when the drop volume is increased and decreased or as the sample surface is tilted (Figure 6).

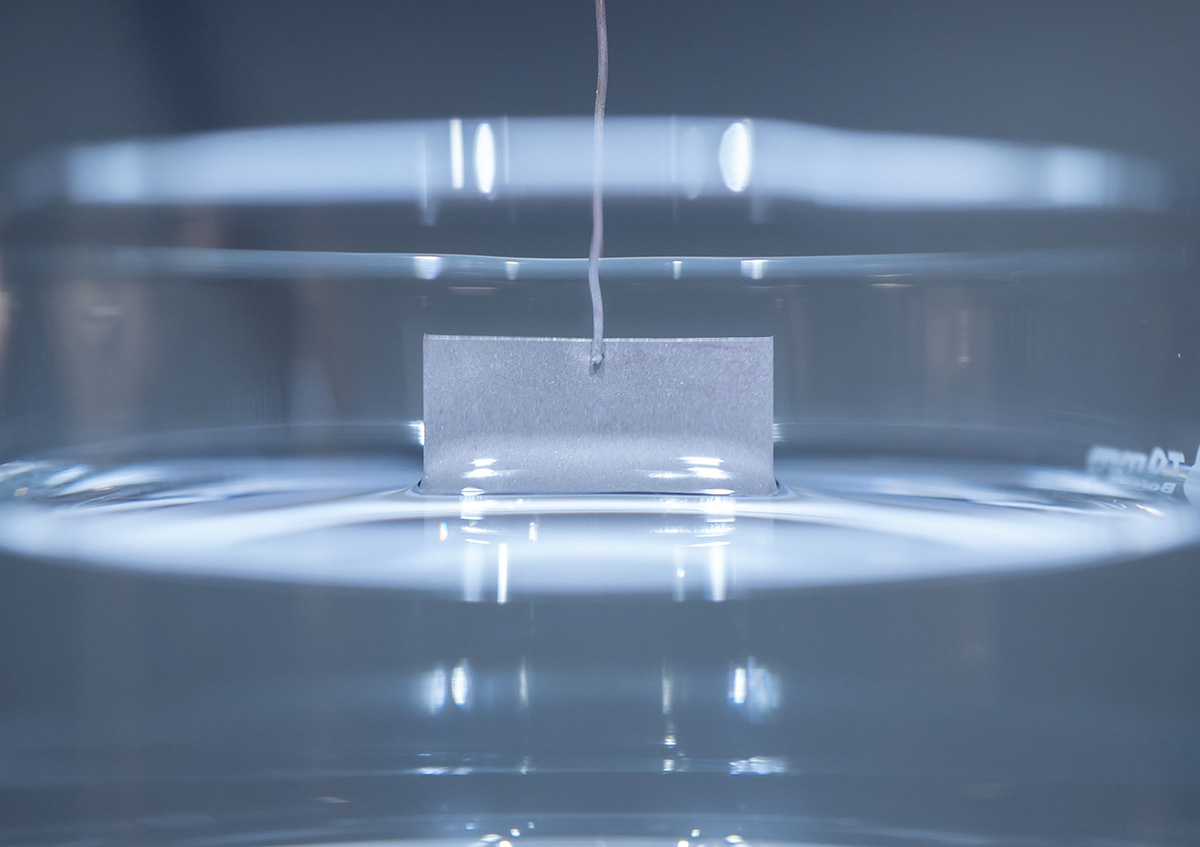

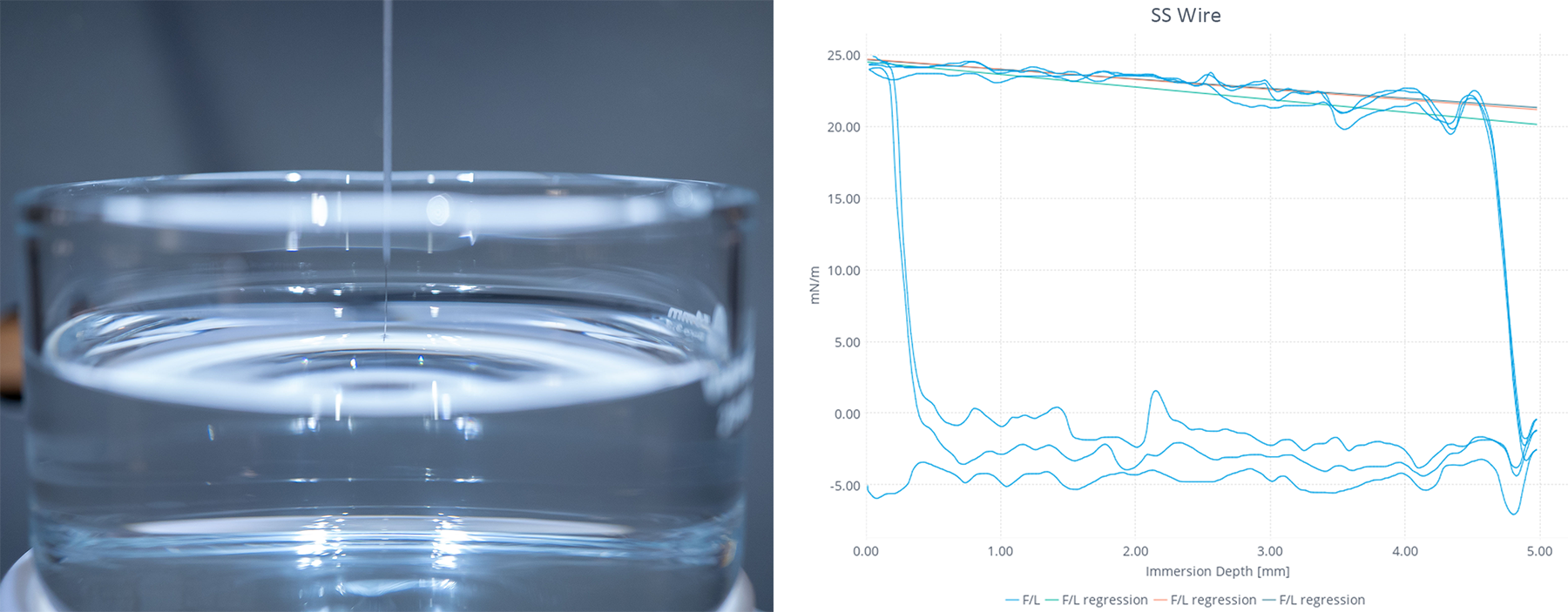

Contact angle can be measured with a force tensiometer using the Wilhelmy plate method: here the solid sample of interest will act as the Wilhelmy plate with a liquid that has a known surface tension. In this measurement a solid with a regular shape like a rectangular sheet or round rod is dipped and withdrawn into a liquid with known surface tension (Figure 8). Contact angle is determined from the force measured during this process and the perimeter of the sample wetted by the liquid (Figure 9).

Which Technique Should be Used?

Optical and force tensiometry measure many of the same surface properties yet use different methods. The best tool for the job depends on the type of measurement and the sample to be studied (Figure 11).

Contact Angle: In general, optical tensiometry offers the most flexibility for measuring contact angle of different samples. Unlike force tensiometry, which requires the sample to have a regular shape with known geometry, optical tensiometry can measure contact angles of samples with irregular shapes and unknown dimensions (Figure 10). A typical contact angle measurement with optical tensiometry also tends to be faster than force tensiometry, making it ideal for routine analysis such as quality control.

| Optical Tensiometry | Force Tensiometry | |||

| Pendant | Du Noüy Ring | Wilhelmy plate | Platinum Rod | |

| Standardized Method | • | • | • | NA |

| Small Volume | R | • | • | • |

| Surfactant Solution | • | • | • | • |

| High Viscosity Sample | • | • | R | • |

| Contaminating Sample | R | • | • | • |

| Temperature Control | • | R | ||

| Pressure Control | • | NA | ||

| Static Contact Angle | • | NA | ||

| Dynamic Contact Angle | • | • | ||

| Interfacial Rheology | • | NA | ||

R indicates the recommended method based on liquid characteristics listed

While force tensiometry is more limited for measuring contact angle, it can be preferred for very specific samples. Due to the highly sensitive balance used in a force tensiometer, contact angle of very small samples with known geometry can be determined with force tensiometry. Force tensiometry is ideal for measuring the contact angle of single fibers (Figure 12). Generating small enough drops to place on these samples for optical tensiometry is difficult and requires specialized optics and small volume liquid dispensers. Force tensiometry can measure contact angle of single fibers with diameters below 10 µm.

Surface Tension: Force tensiometry is preferred for measuring surface and interfacial tension when a standardized measurement method is needed. Due to being a very established technique, force tensiometry is the most common method used in both international and industrial standards to define surface tension. For interfacial tension measurements, force tensiometry, particularly using the du Noüy ring, is typically preferred over optical tensiometry. Measuring interfacial tension with optical tensiometry requires one liquid to be transparent, while force tensiometry has no such limit. Force tensiometry is also useful for liquids where the density is unknown since the Wilhelmy plate measurement does not require knowing any liquid density.

Optical tensiometry offers some advantages over force tensiometry in certain situations. The volume of sample required for a pendant drop experiment is significantly lower than that required for a du Noüy ring or Wilhelmy plate measurement (microliters compared to milliliters of sample). For samples where volume is limited, optical tensiometry is ideal. Optical tensiometry is also ideal for samples that are difficult to remove from the measurement device. When measuring surface tension with force tensiometry, the probe and vessel used to hold the liquid sample must be thoroughly cleaned for accurate results. For difficult to clean samples like paints or oils, this cleaning process can become tedious and time-consuming. In optical tensiometry, the possibility to use disposable pipette tips for pendant drop measurements can simplify cleaning between measurements and avoid contamination

Tensiometers To Use for These Measurements

The Attension Theta line of Optical Tensiometers (Figure 13), also called goniometers or drop shape analyzers, are highly versatile instruments designed for comprehensive surface and interfacial tension measurements across diverse applications. Leveraging high-resolution cameras and sophisticated image analysis software, Attension Theta tensiometers deliver accurate contact angle measurements, which are critical for assessing wettability, adhesion, and surface free energy (SFE). With customizable software and free access to all measurement modes, including static and dynamic contact angle, surface free energy, and interfacial tension, the Theta optical tensiometers cater to both research and industrial needs. Their adaptability to samples of various sizes and geometries, and flexibility in liquid dispensing, coupled with the advanced OneAttension software for streamlined data analysis, make the Theta series of instruments essential tools for surface science, materials research, product development, and industrial manufacturing.

The Attension Sigma Force Tensiometers (Figure 14) are precision instruments engineered for advanced surface and interfacial tension measurements using the Wilhelmy plate, Du Noüy ring, and other methods that employ a probe and microbalance. Almost any material can be used as a hanging probe, accommodating a wide range of sample types. These tensiometers excel at characterizing liquid properties such as surface tension, interfacial tension, and density, as well as material properties such as powder wettability, absorption rates, and dynamic contact angles. They are also useful for studying surfactants (CMC), emulsions, and other complex fluids. The Sigma tensiometers provide accurate and reproducible data, while offering the flexibility to run customizable automated protocols or utilize the library of pre-programmed standards (e.g. ASTM D971). The automated functionality, high precision, and comprehensive data analysis capabilities ensure that Sigma tensiometers are integral to surface chemistry, materials research, and product formulation processes.