Quartz Crystal Microbalance with Dissipation monitoring (QCM-D) has revolutionized surface science by enabling real-time analysis of molecular interactions.1 However, traditional QCM-D workflows often involve time-consuming manual processes that introduce variability and inefficiency. In most QCM-D systems, sensor mounting, determining the resonance frequencies, stabilizing the baseline in air, priming the sensor, and establishing the baseline in liquids are performed manually.

With the integration of automation, researchers can significantly enhance the accuracy, reproducibility, and speed of their experiments. Biolin Scientific has developed the QSense Omni, an industry leading Quartz Crystal Microbalance with Dissipation monitoring (QCM-D) instrument designed to facilitate precise and reproducible measurements of surface interactions. It incorporates several automation features that enhance user efficiency and data reliability. This blog explores how automation in QCM-D maximizes efficiency in surface interaction studies.

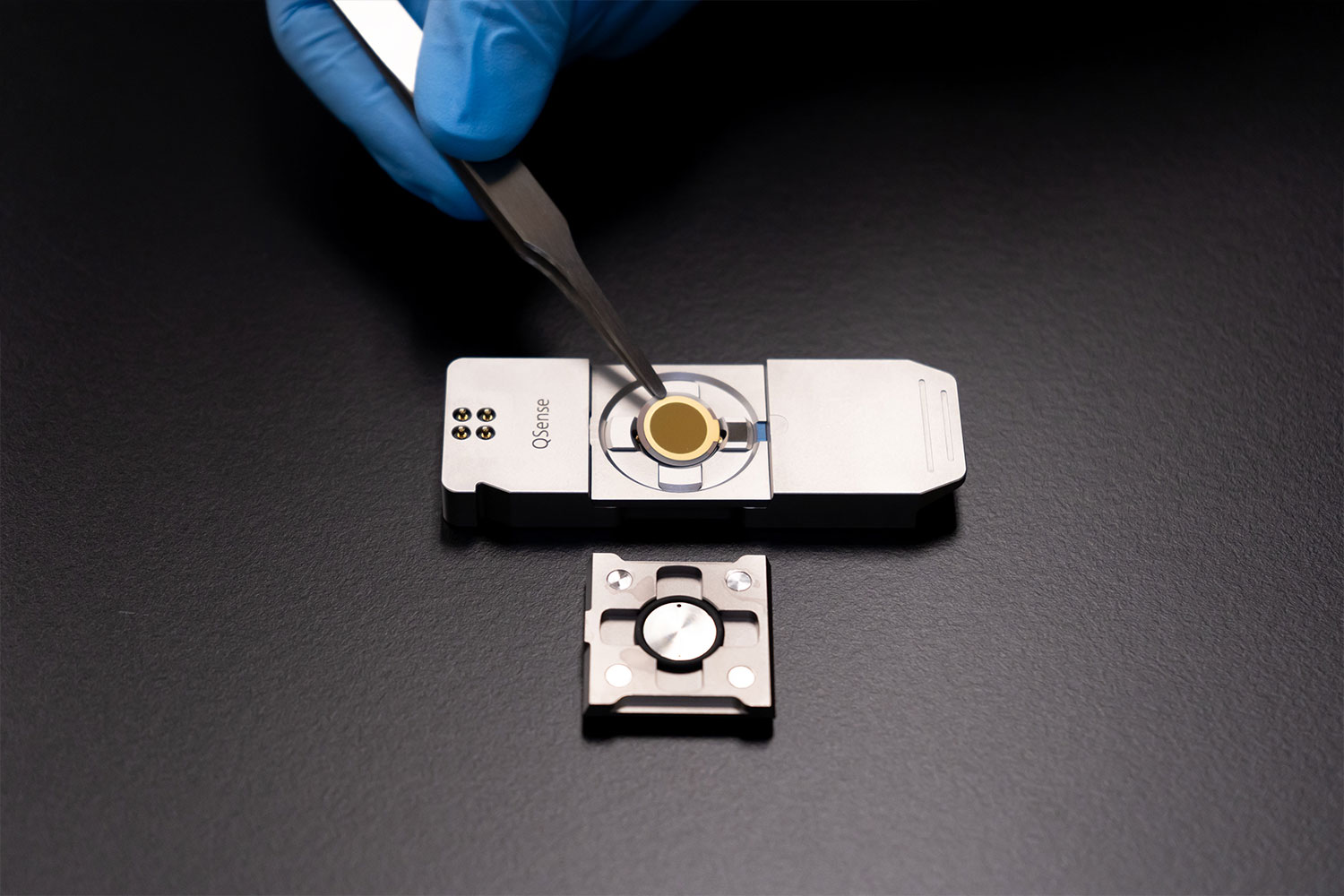

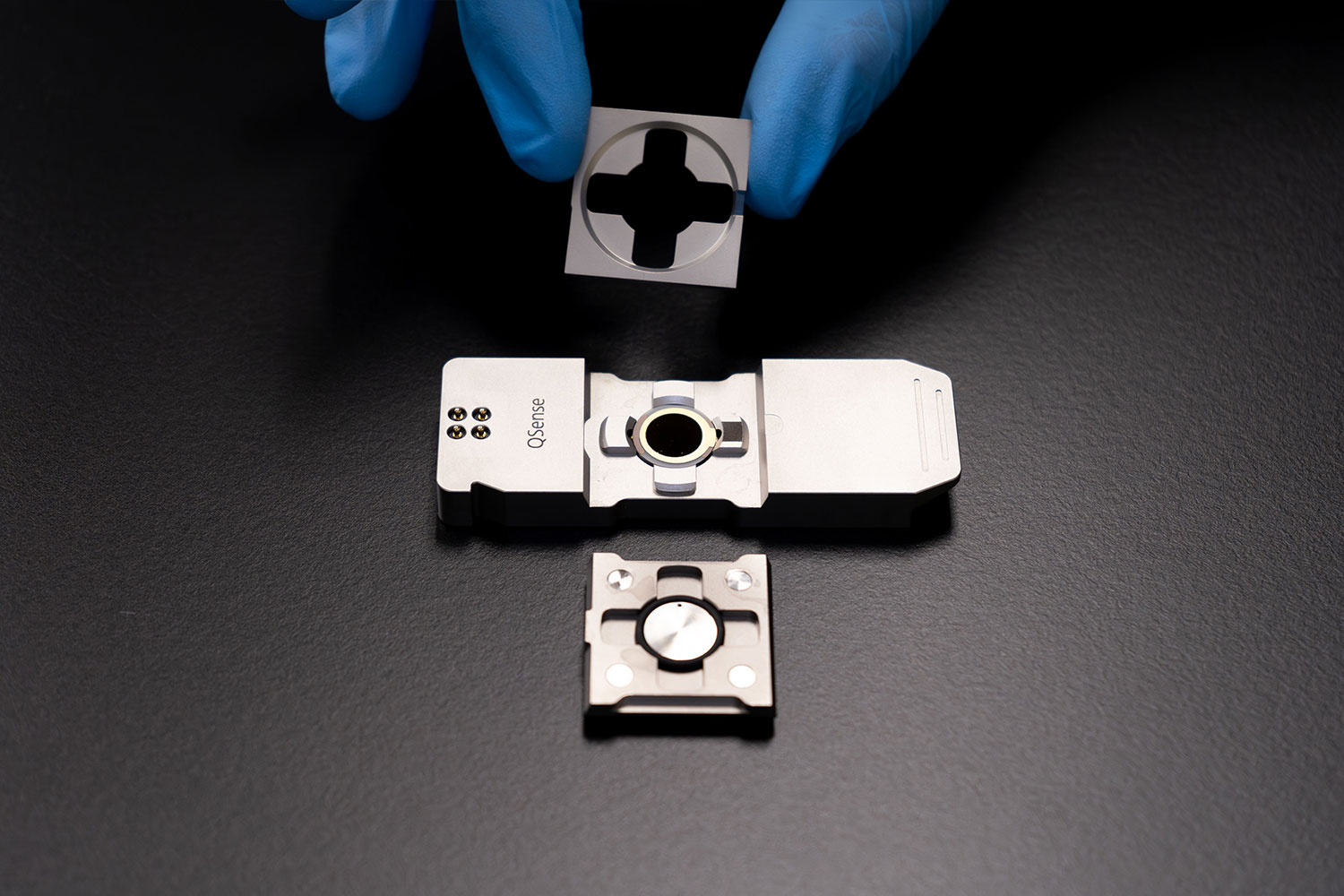

Semi-Automatic Sensor Mounting

Manual sensor mounting causes differences in sensor positioning and the tightness of the mounting O-rings each time a sensor is mounted, leading to inconsistencies in the initial signals.

The QSense Omni features semi-automatic sensor mounting, which facilitates correct and repeatable sensor installation. A sensor mounting guide is provided to ensure correct sensor positioning. The motorized clamping system for the sensor and sample holder guarantees even pressure distribution along the sensor edges and precise tightening of the mounting O-rings. This design reduces manual handling and potential errors during sensor setup, thereby enhancing the reliability of the measurements.

Automated Quality-Controlled Measurements

The QSense Omni provides automated quality checks after sensor mounting, which significantly reduces user involvement and allows for parallel execution of the next steps. These automatic checks ensure that each experiment follows a standardized process, minimizing potential user-induced variability and improving the reproducibility of experimental results.

Immediately after sensor mounting, the Omni software activates the sensor and begins the set-up quality checks, which include:

- Determining resonance frequencies and dissipation at various harmonics

- Stabilizing temperature at the set value

- Stabilizing the baseline in air based on user-defined criteria

- Priming the chamber with a defined prime liquid

- Stabilizing the baseline in liquid according to user-defined criteria

- Preparing the system to run the experiment script

Automated Sample Handling

Efficient sample delivery involves a sharp solvent exchange above the sensor with minimal mixing between samples in the flow lines and requires a low overall volume. The manual liquid handling in conventional QSense systems involves sample flow through tubing that demands larger sample volumes and leads to mixing in the flow lines.

The QSense Omni includes fully automated sample handling capabilities to streamline the experimental process. The sample containers are placed directly on the sample holder and are delivered over the sensor by a syringe pump mounted within each individual channel. A specially designed disc rotator directs the flow of the designated liquid (as specified in the measurement script) toward the measurement chamber. The liquid primes the flow path before being injected into the sensor chamber, ensuring minimal unwanted diffusion and enabling fast, precise liquid exchange. These features reduce the time and potential errors associated with manual sample introduction, ensuring more reliable and reproducible results.

Patented temperature control reaction chamber

Temperature fluctuations can greatly impact measurements in QCM-D studies, leading to unwanted frequency drift that can be mistaken for mass or other surface changes. The Omni’s patented temperature-control system with an operating range 4 °C – 70 °C, ensures stable, accurate and reproducible measurements.

Omni achieves precise temperature control through its advanced internal design and multiple temperature sensors, which maintain consistent temperature across the samples, sample flow paths, and sensors. An external water circulator is used to help achieve high and low temperatures.

Live Script Editing

QSense Omni’s software enables custom design of experimental protocols and supports live script editing, allowing users to develop and refine experimental protocols in real-time. This flexibility enables quick adjustments to experimental parameters and ensures that researchers can quickly adapt to unexpected results without interrupting the workflow. This facilitates efficient optimization of experimental conditions.

- The “drag and drop” feature of the Omni software allows users to add desired solution steps to the script.

- Unwanted solution steps can be easily removed by clicking the delete icon next to the intended step.

- The duration of the solution flow can be adjusted in real time by extending or reducing the flow time.

- A solution “pause” can be added to the script at any point to create static flow conditions.

Automated Cleaning Procedures

Cleaning the instrument between measurements and at the end of the process is essential to prevent cross-contamination and ensure the accuracy of the results and proper instrument maintenance. The cleaning procedure involves multiple steps, including draining the flow lines, flowing cleaning solutions, and rinsing with clean solvent. This multistep cleaning process is time-consuming and requires the user’s presence when using manual QSense instruments.

The Qsense Omni is equipped with an automated cleaning function that prepares the system for experiments. This automation not only saves time but also ensures that the system is free from contaminants that could affect the accuracy of future measurements. Automated cleaning routines eliminate manual errors and ensure that the instrument is always prepared optimally for subsequent experiments.

Upon completion of the experiment script, the sample containers are drained into the waste bottle. Cleaning of the pump valves and the sample holder is then initiated by first drawing cleaning liquid from a designated bottle in the Omni’s bottle compartment, followed by rinsing with clean solvent from another bottle in the compartment. This process is repeated several times to ensure thorough cleaning.

Conclusion:

Automation in QCM-D, exemplified by advanced instruments like QSense Omni, is transforming the landscape of surface interaction studies. By integrating advanced automation features such as automated quality-controlled measurements, cleaning procedures, semi-automatic sensor mounting, automated sample handling, and live script editing, researchers can significantly improve efficiency, accuracy, and reproducibility in their experiments. Automation minimizes the need for constant user intervention, freeing up researchers to focus on data analysis and interpretation. As technology continues to evolve, automation will remain a cornerstone of high-precision QCM-D research, driving innovation in materials science and life sciences.

- Johannsmann, D.; Reviakine, I. Quartz crystal microbalance with dissipation monitoring for studying soft matter at interfaces. Nature Reviews Methods Primers 2024, 4 (1). https://doi.org/10.1038/s43586-024-00340-4. ↩︎