Particle analysis involves characterizing the size, morphology, and composition of powders and particulate matter to describe their properties in a precise and statistically significant manner. Some of the most common areas where particle analysis is critical are in advanced manufacturing, forensic analysis, and environmental applications.

Among the different techniques for conducting particle analysis, scanning electron microscopy (SEM) stands out as the most comprehensive method. SEM effectively addresses the most common challenges encountered with conventional particle analysis approaches while providing complete information about a sample. The ability to obtain high resolution images, combined with energy-dispersive X-ray spectroscopy (EDS), allows scientists to measure the size, shape, and composition of individual particles. However, traditional SEM methods often require significant time and manual effort to collect and analyze large datasets, limiting their practical applicability.

Automated SEM solutions streamline the particle analysis workflow by integrating data acquisition, feature detection, and high-throughput analysis. By reducing manual intervention and increasing reproducibility, automation enables researchers and quality control teams to analyze thousands of particles quickly and with greater accuracy. In this blog, we’ll explore how automation enhances SEM-based particle analysis and its key applications across various industries.

How Automation Enhances SEM for Particle Analysis

Traditional SEM workflows often require repetitive manual adjustments for optimizing the imaging conditions, moving the stage to image the sample at multiple locations, in addition to the tedious task of analyzing images. These challenges can be a significant barrier for organizations looking to bring advanced particle analysis in-house, often leading them to outsource these efforts instead.

Automated SEM solutions seamlessly integrate microscope hardware and software, enabling user-independent data collection and analysis with minimal input. Users only need to set initial parameters—such as defining the imaging area, entering sample information, and selecting the analysis protocols to meet their specifications. By automating these steps, organizations can accelerate their time to results by up to 10 times (vs outsourcing), making in-house SEM essential for maintaining a competitive advantage.

Automation solutions enhance three key aspects of SEM workflows for particle analysis:

- Increased throughput: Automated SEM can analyze thousands of particles in a fraction of the time required for manual analysis.

- Reproducibility & accuracy: Standardized workflows reduce human error and enable the analysis of larger sample areas, resulting in more statistically robust measurements.

- Data processing & classification: Automated image thresholding and feature measurement algorithms systematically identify, measure, and classify particles based on predefined parameters (e.g., size, morphology, and composition), ensuring consistent and reliable results.

Applications of Particle Analysis using Automated SEM

Particle analysis via automated SEM is quickly becoming the standard across industries for providing in-depth information about material properties, product quality, and contamination sources. Here are some of the key applications where automated SEM is making a significant impact:

Environmental Monitoring

In cleanrooms, manufacturing environments, and pollution studies, automated SEM is used to detect and classify airborne particles. This is critical in semiconductor fabrication, pharmaceutical production, and other industries where even microscopic contaminants can impact product quality. The ability of automated SEM-EDS to provide particle composition enables scientists to pinpoint potential root causes of particulate contamination and take corrective action to minimize future occurrences

Fluid Cleanliness

In industries such as automotive, aerospace, and hydraulics, fluid cleanliness is essential for preventing system failures. Automated SEM can identify and classify particulate contaminants in lubricants, coolants, and fuels, helping maintain optimal performance and extend equipment lifespan.

Semiconductors

Automated SEM is used in semiconductor and microelectronics fabrication to detect and analyze nano-scale defects, contaminants, and process-related residues. High-throughput analysis ensures better yield optimization and process control in microelectronics manufacturing.

Automotive

Automated SEM enables technical cleanliness evaluation by detecting and classifying contaminants on engine parts, coatings, and electrical systems. Integrated EDS provides a comprehensive analysis of particle size, shape, and composition, helping identify contamination sources and ensure component quality.

Pharmaceuticals

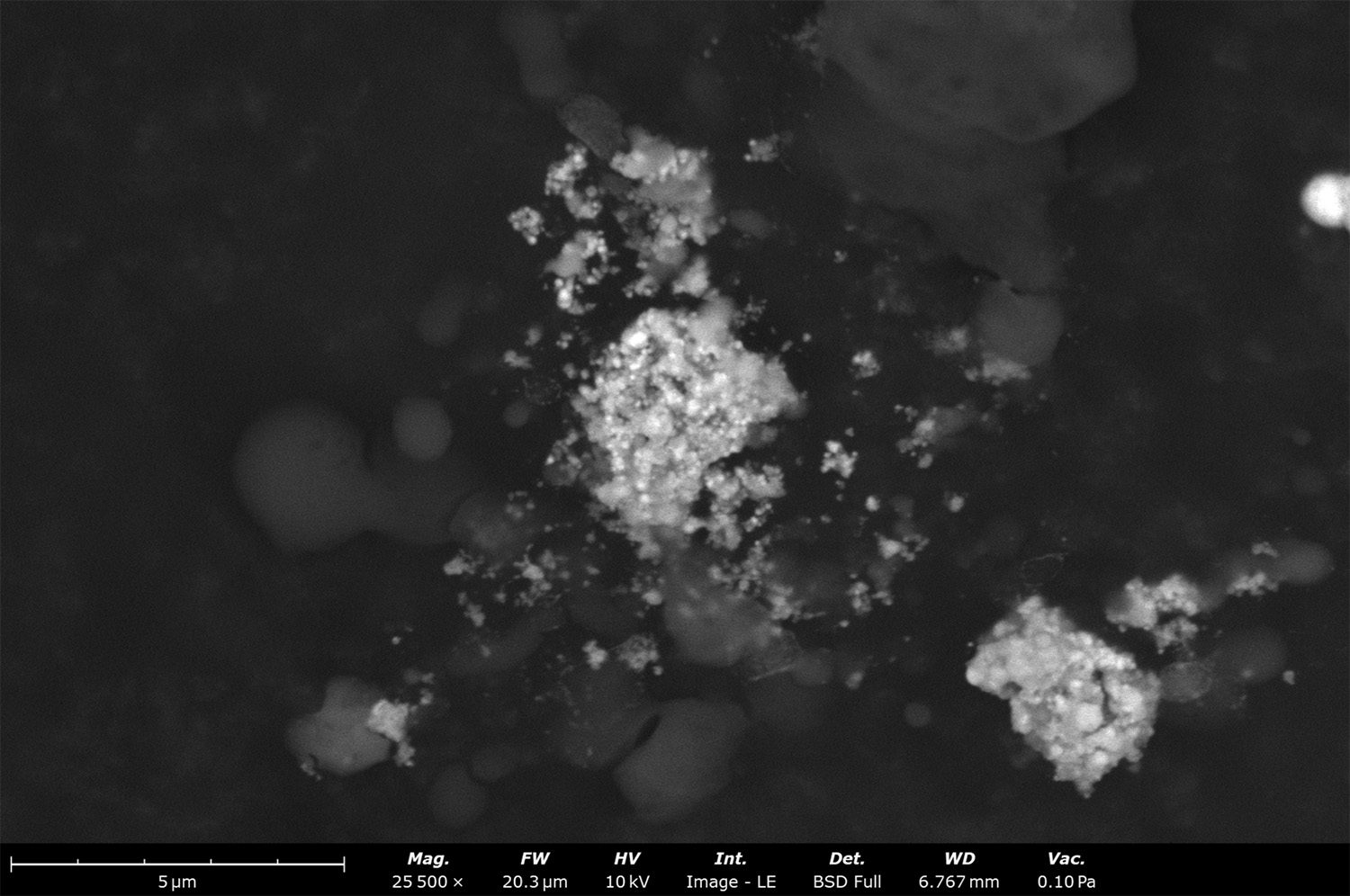

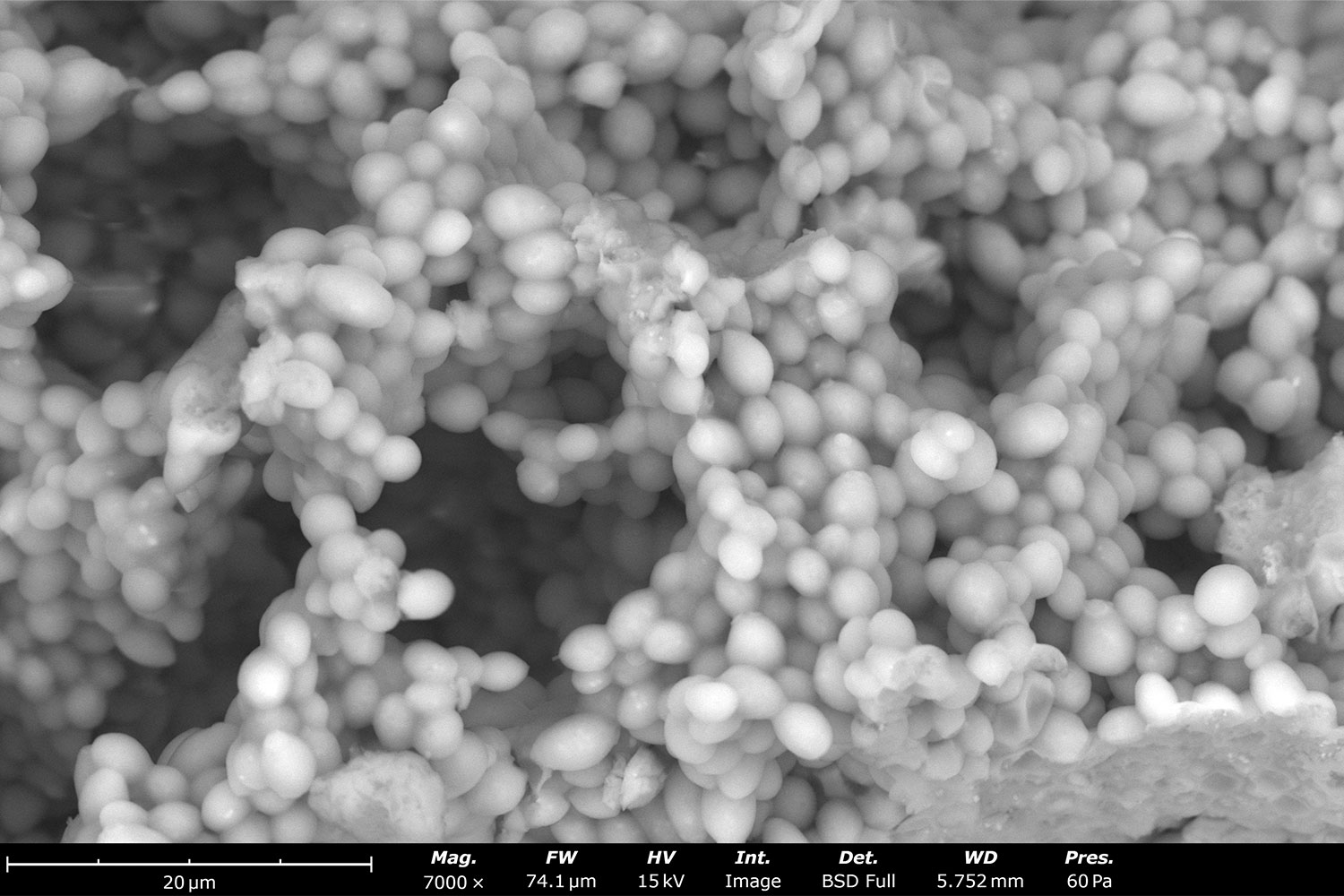

Automated SEM plays a crucial role in pharmaceutical quality control by detecting foreign particles in drug formulations and packaging, analyzing excipient size distribution, and ensuring batch-to-batch consistency.1 Figure 1 shows SEM images of different types of particle morphologies found in pharmaceutical compounds that were captured with a Phenom Desktop SEM using a backscattered electron detector.

Metallurgy

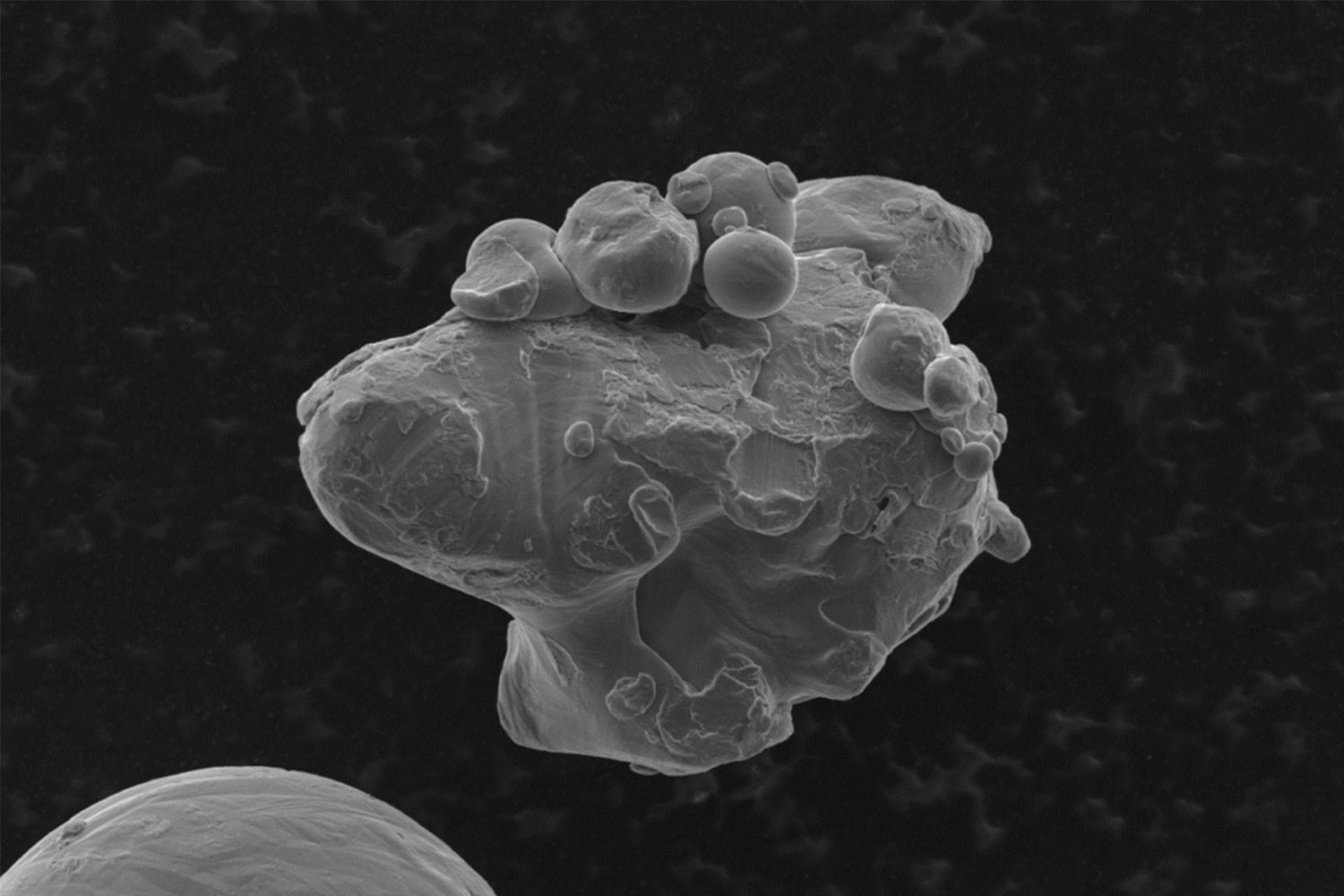

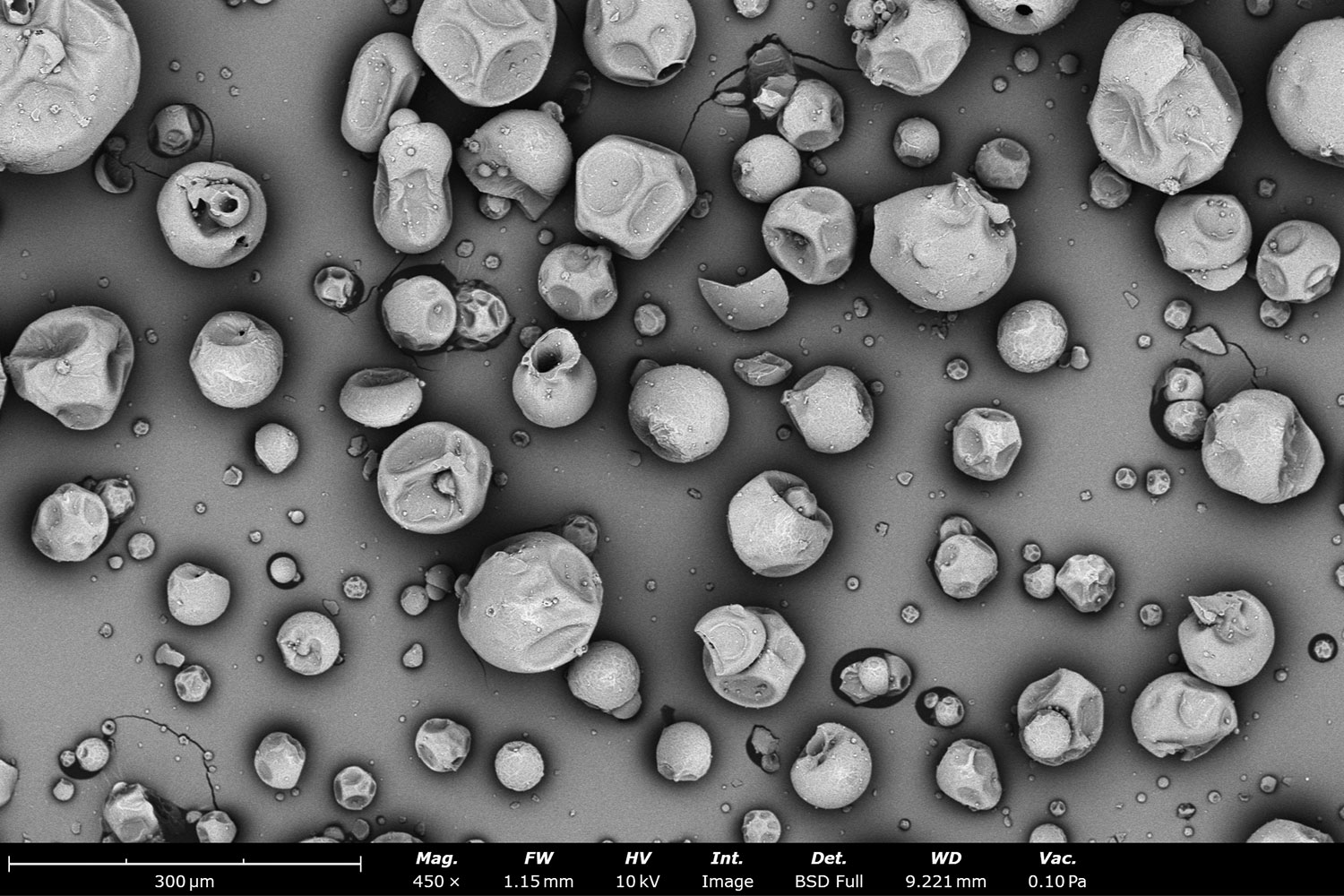

In metallurgical applications, automated SEM is used for detecting inclusions or impurities – such as in steel or aluminum alloys. Inclusions are often composed of multiple elements, including metals and non-metallic elements, as seen in Figure 2. While certain non-metallic inclusions offer benefits, others can be detrimental, leading to manufacturing issues or compromising the mechanical properties of the final product. Gaining insight into these inclusions is crucial for enhancing steel quality and ensuring material performance in aerospace, construction, and industrial applications.

Forensics

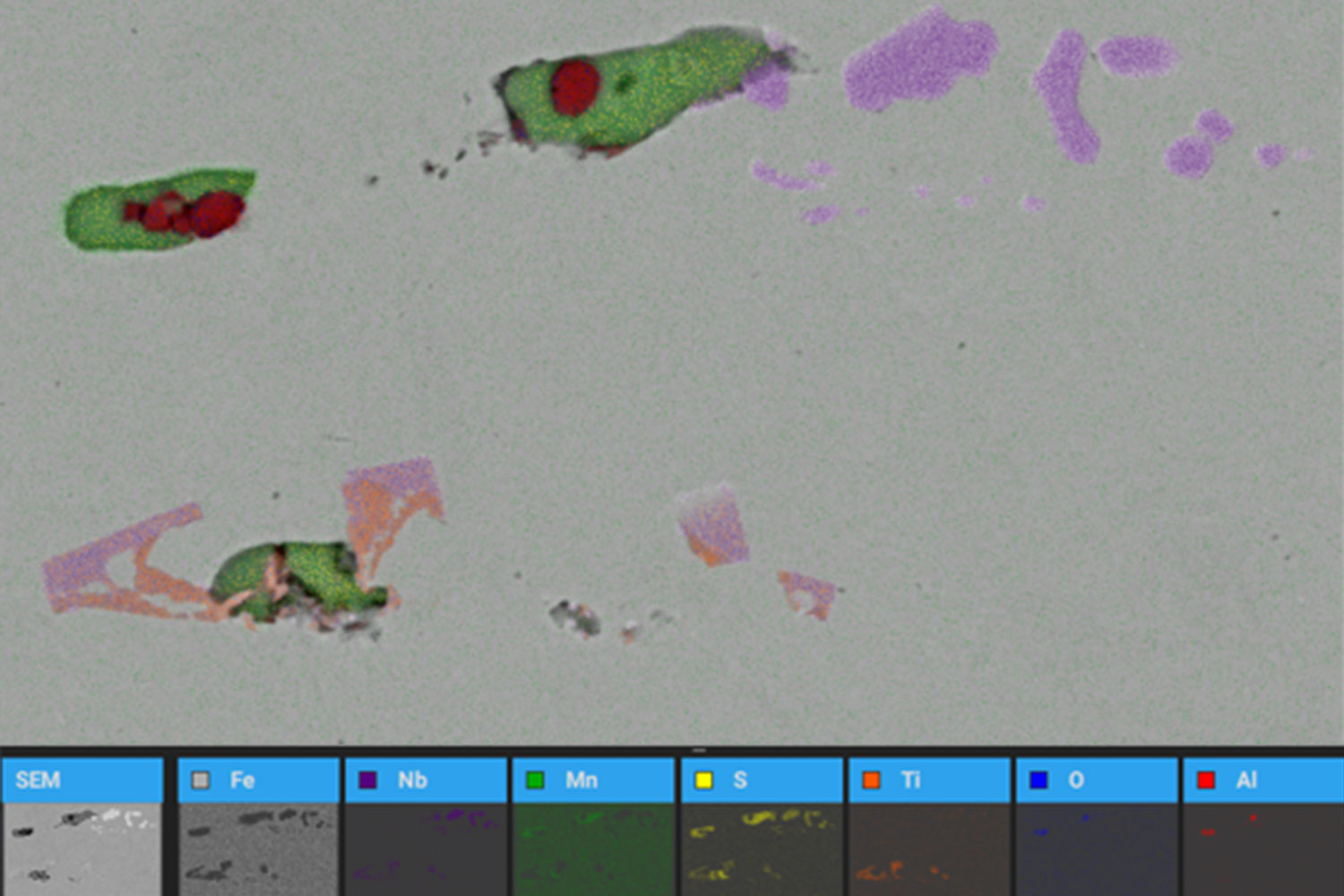

Automated SEM combined with energy dispersive spectroscopy (EDS) is the leading method for detecting and analyzing gunshot residue (GSR), as shown in Figure 3. In addition to GSR, automated SEM is widely used for identifying and categorizing other types of trace evidence, including paint fragments, fibers, and plant material. By linking these materials to specific sources or individuals, trace evidence analysis plays a crucial role in criminal investigations

Batteries & Fuel Cells

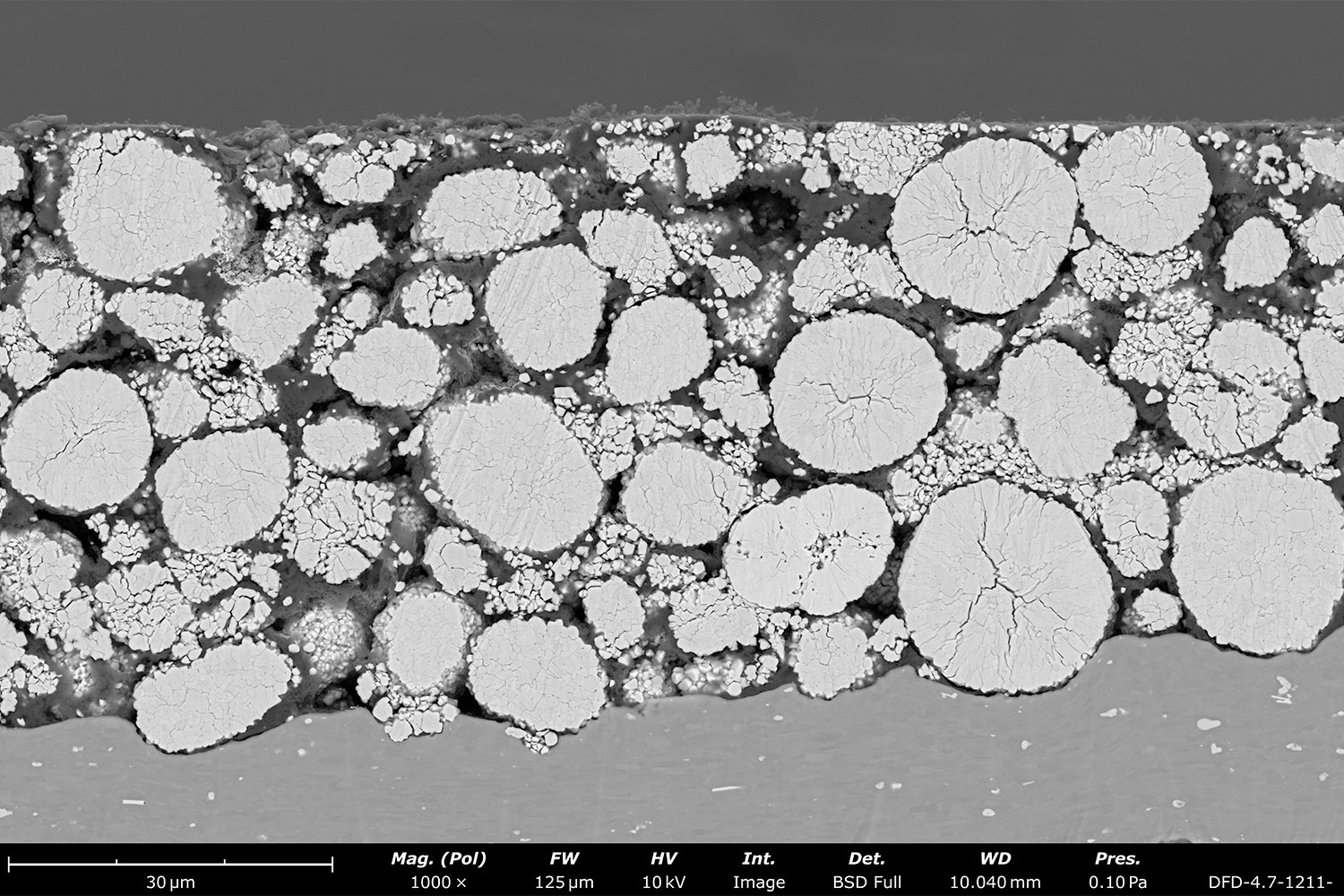

Characterizing the microstructure of battery and fuel cell components, such as cathodes (Figure 4), anodes, and separators, is essential for linking properties and defects to product performance2. Automated SEM enables high-throughput analysis of particle size, fiber diameter, porosity, and composition, allowing for efficient yet statistically significant measurements of these key material properties.

Additive manufacturing

Powder characterization is critical in additive manufacturing (3D printing), where particle size, shape, and distribution directly impact material flow and final product quality3. Automated SEM provides rapid and consistent analysis, ensuring process stability and repeatability. It is also greatly beneficial for evaluating recycled AM powders to identify agglomerates (Figure 5) and how much the power properties have deviated from virgin material.

Conclusion

Automated SEM provides rapid, high-resolution particle analysis, delivering comprehensive data on size distribution, morphological features (e.g., convexity, aspect ratio), and particle-by-particle composition in a far more efficient manner than manual or outsourced methods. By standardizing workflows and minimizing human error, automation ensures consistent, high-quality results while meeting regulatory requirements. As industries increasingly adopt automated SEM for faster, more reliable particle analysis, its impact continues to grow across applications in quality control, failure analysis, and research.

If you are interested in implementing automated SEM in your organization, explore our past webinar “What is ParticleX? Automated Particle Analysis for Scanning Electron Microscopy”, or contact us for a product demonstration.

References

- Klang, V.; Valenta, C.; & Matsko, N.B. Electron microscopy of pharmaceutical systems. Micron 2013, 44, 45. https://doi.org/10.1016/j.micron.2012.07.008 ↩︎

- Guragain, D.; Zequine, C.; Poudel, T.; et.al. Influence of Urea on the Synthesis of NiCo2O4 Nanostructure: Morphological and Electrochemical Studies. Journal of Nanoscience and Nanotechnology 2020, 20, 2526. https://doi.org/10.1166/jnn.2020.17366 ↩︎

- Tammaro, L.; Martone, A.; Palmieri, B.; et.al. Reinforcing Efficiency of Recycled Carbon Fiber PLA Filament Suitable for Additive Manufacturing. Polymers 2024, 16, 2100. https://doi.org/10.3390/polym16152100 ↩︎