Introduction

Electrochemistry and electrochemical reactions have been important in a wide range of industries, from understanding the corrosion behavior of metals and metal structures to the development of batteries for mobile electronics and electric vehicles. Studying these systems requires precise testing equipment that is versatile, with flexible software to program experiments and adjust settings. Electrochemical systems can exhibit current changes over a wide range from picoamps (pA) and nanoamps (nA) for coated systems and microelectrodes, to milliamps (mA) and amps (A) for batteries and fuel cells. The voltage measurement range is also challenging with small voltage changes as low as microvolts (mV) for some systems. Making measurements over this wide range of current and voltage is challenging and often requires a specialized potentiostat based on the requirements of the application.

What is a Potentiostat and Why Use One?

A potentiostat is an analytical instrument that is both a controlling and measuring device. A potentiostat controls/measures the voltage by varying the current it supplies to the system through the counter electrode. Potentiostats have the advantage over source meters and voltmeters in that they have high impedance inputs on the voltage measurement circuitry and high-resolution measurement channels for the current and voltage. In addition, potentiostats can accurately control a three-electrode cell by providing precise current-voltage information about the sample electrode or electrochemical system of interest. Potentiostats also incorporate many decades of current measurement to cover the wide range a user would require. As well as controlling the voltage, most potentiostats can operate in galvanostatic mode wherein it can control the current.

The potentiostat is the favorite instrument for measuring electrochemical systems. Many users indicate that they only need a simple potentiostat without realizing that even a basic potentiostat is a complicated piece of electronic engineering, which must be capable of controlling a wide variety of measurement cells.

Common Potentiostat Applications

Corrosion

Corrosion rate and corrosion investigation measurements require a potentiostat that can be both sensitive and handle larger currents. For non-destructive corrosion rate measurements, the ability to measure low currents is of prime importance. More general corrosion studies looking at the qualitative behavior of materials in a corrosive environment may require higher current measurement.

Paints and Coatings

Organic painted metal surfaces are one of the most challenging samples on which to make electrochemical measurements. Traditional DC measurements are not very useful in understanding the behavior of coated materials. Electrochemical impedance spectroscopy (EIS) is the preferred measurement technique for investigating coatings. High-quality coatings have very high impedances which translate to very small currents that require both a sensitive potentiostat and a Faraday cage to shield the sample from external electrical noise. Metal surfaces coated with conductive coatings behave like bare metal surfaces and can be evaluated with similar equipment used for uniform corrosion testing.

Physical and Analytical Electrochemistry

Physical electrochemistry involves measurements on macro or micro-sized electrodes with currents ranging from mA to possibly into the nA or pA range. Voltages tend to be fairly low, +/- 2V around zero.

Battery Materials Testing

Battery Materials testing involves low current measurements on small area electrodes with currents in the µA range. Battery materials testing does not involve very rigorous protocols if the data is accurate. EIS is a useful additional tool to give a fundamental understanding of the electrochemical reactions that are taking place.

Battery Testing

Unlike materials testing, testing whole batteries requires more current and power. The protocols are similar to those for materials testing but at much higher currents and possibly with more complicated current profiles like the urban drive cycle. Constant resistance and constant power modes may also be used to simulate battery use in a real-world environment.

Sensors

Sensors in general are not very taxing samples to measure for most potentiostats. However, in certain cases, small currents may need to be measured especially if approaching the limit of detection of the analyte.

Fuel Cells and Electrolyzers

Fuel cells and electrolyzers can deliver very large currents for quite small geometric surface areas. This is because of the catalyst layer on the electrode, which is porous and has a large surface area, and the close distance between the 2 electrodes yielding low resistance. Single or small stacks of cells can be tested with low power potentiostats, but larger stacks of cells with higher voltage need higher power systems.

Which Ivium Potentiostat is best for your application?

PocketStat2/PocketStat2.LC

PocketStat2/PocketStat2.LC are powered by USB and are ideal potentiostats for field applications like corrosion monitoring or coated structure testing. The addition of iBlue, a battery pack with an integrated Bluetooth connection, allows for wireless connection to the computer and makes Pocketstats a truly portable system.

CompactStat

CompactStats are small USB-powered potentiostats that are also good for corrosion measurement and coatings evaluation. It is available with additional internal boosters to increase the available current for measuring corrosion behavior. It is also ideal for sensors, analytical, and physical electrochemistry because of its sensitivity and resolution.

Vertex.One

The Vertex.One is an entry level potentiostat suitable for corrosion measurements and laboratory measurements in physical electrochemistry.

Vertex Line

Vertex line is an extensive line of potentiostats with several models that meet the needs of most applications. The Vertex.100mA and Vertex.1A are appropriate for corrosion and general electrochemistry experiments as well as battery materials and small batteries like coin cells. The Vertex.5A, 10A and 20A are suitable for larger batteries and fuel cell, electrolyzer, and redox flow battery measurements. The Vertex.20V, Vertex.1A20V and Vertex.1A50V are suitable for higher voltage systems like stacks of batteries and fuel cells.

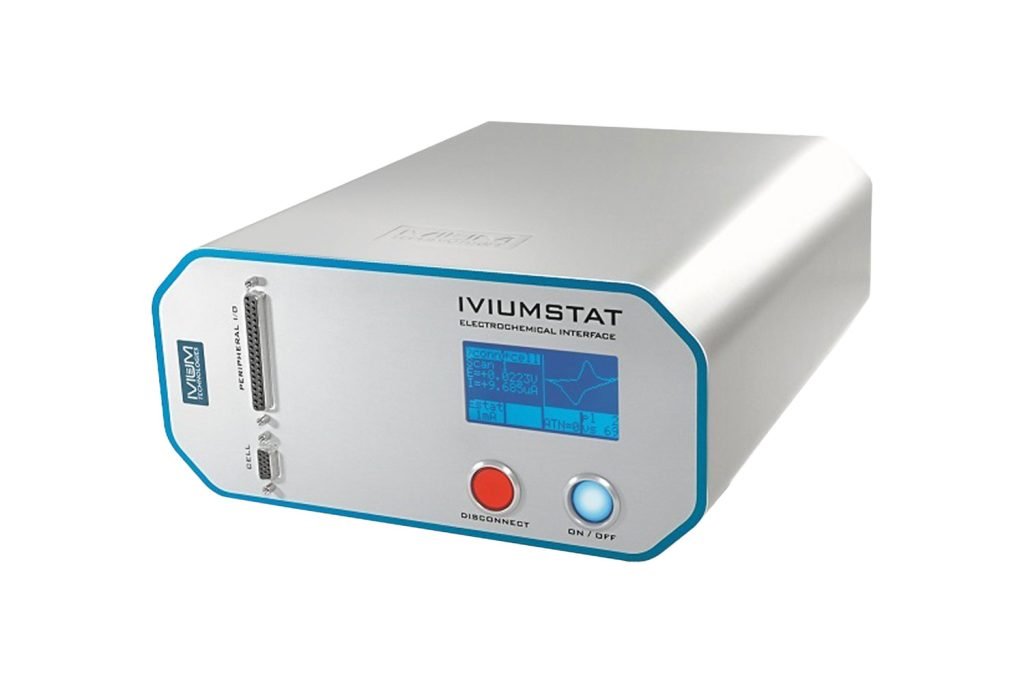

IviumStat.h

The IviumStat is the flagship potentiostat which is suitable for a wide range of electrochemical applications from coatings testing to batteries and fuel cell testing.

XP

XP range of potentiostats are designed for higher current and voltage applications with models that can reach 40A or 40V. Applications for these instruments include fuel cell and electrolyzer testing and battery and battery stack testing.

Conclusion

The potentiostat is a vital component for electrochemical research and development and choosing the right one can be a daunting task with numerous models with overlapping specifications. We have identified some of the characteristics important for different applications and we have listed some of the major characteristics of various potentiostats to enable you to make the correct choice based on your needs.

| PocketStat2 | CompactStat | Vertex.one | Vertex | IviumStat | XP | ||

| Corrosion | |||||||

| Paintings and coatings | |||||||

| Battery materials testing | |||||||

| Battery testing | |||||||

| Fuel cells and electrolyzers | |||||||

| Sensors | |||||||

| Physical Electrochemistry | |||||||