Electrospinning is an emerging technology in the medical device industry, offering precise control over material properties and structure at the nanoscale. Its ability to produce intricately designed scaffolds and functional materials has impacted areas such as wound healing, tissue engineering, and drug delivery systems. By leveraging electrospinning, medical device manufacturers can tailor materials to meet specific biological and mechanical requirements, resulting in enhanced performance and better patient outcomes. This versatile technique continues to drive innovation, promising new advancements in medical device design and functionality.

Medical Devices

Medical devices are considered as any instrument, apparatus, implement, machine, appliance, implant, reagent for in vitro use, software, material, or other similar or related article, intended by the manufacturer to be used, alone or in combination for a medical purpose [1]. These many devices are what make essential procedures possible, aiding in diagnosis, treatment, assistance for various disabilities, and prevention or intervention of illnesses, both acute and chronic. Over 2 million types of medical devices are estimated to be in the world market with over 7,000 generic device group categorizations among them. With such a wide range of applications, medical devices are used by everyone including laypersons at home, paramedical staff and clinicians in remote clinics, specialists like opticians and dentists, and especially healthcare professionals in advanced medical facilities [1]. Their ubiquity necessitates facile, reliable, and precise fabrication and manufacturing techniques.

Electrospinning

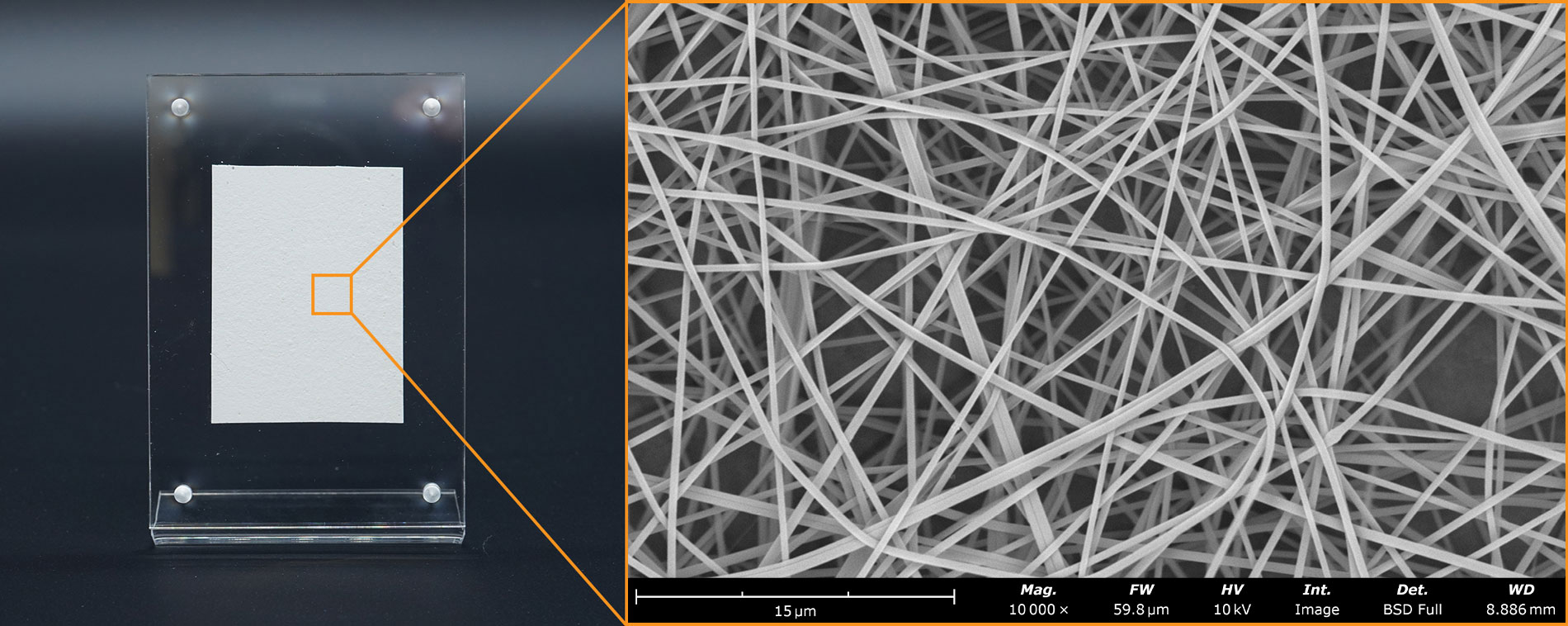

Electrospinning is an electrohydrodynamic process that can fabricate fibers of various materials, from nanoscale to microscale. It is a room-temperature technique that can be used to process a variety of polymers and even incorporate additives like ceramics, metals, APIs, and biomolecules. It is a versatile technique that allows for the tailoring of material properties, surface characteristics, and functionality. Electrospun fibers can be used to fabricate medical devices or coat devices fabricated by other means to make them biocompatible, mechanically robust, or to impart specific functionalities. The orientation of electrospun fibers can also be controlled to generate both random and aligned fibers which could be useful in different scenarios.

Applications of Electrospinning

Materials fabricated by electrospinning possess unique properties that make them valuable for various applications in medical devices, biomaterials, drug delivery, and other applications. Four primary areas of application of electrospun materials are a) wound healing and dressings, b) drug delivery systems, c) tissue engineering and regenerative medicine, and d) implantable devices and biocompatible materials.

Wound Healing and Dressings

Electrospun fibers can be used to create wound dressings with enhanced properties. The high porosity and engineerable structure of fibers promote efficient moisture management, gas exchange, and tissue integration, which are essential for wound healing. Tunable sizes and morphologies of the fiber scaffold, like micronized nanofibers, can be used for direct injection or application to full thickness, tunneling, or otherwise complex-shaped or difficult-to-treat wounds for increased efficacy. Active agents, such as antimicrobial agents or growth factors, can be easily incorporated into the fibers to aid the healing process. Furthermore, the fibers can be tuned for distinct bioresorbability profiles (e.g. via hydrolysis) such that successful integration of native tissues is simultaneously promoted.

Drug Delivery Systems

Electrospun fibers can serve as drug delivery platforms. Drugs or therapeutic agents can be encapsulated within the fibers, allowing protection of the therapeutics and controlled release over time. The nanoscale structures provide a large surface area for drug loading, and the release rate can be tailored by adjusting the composition and morphology of the fibers. The inherent small dimensions of the nanoscale materials can allow for suspension and injectability directly to target tissues, enhancing therapeutic efficiency and patient comfort. Electrospun scaffolds can be fabricated to mimic the extracellular matrix (ECM). The incorporation of drugs on such electrospun scaffolds allows the material to have the versatility of resembling the in vivo environment while improving healing effects with the incorporated drug.

Tissue Engineering & Regenerative Medicine

Electrospun nanofibers can mimic the ECMs structure and provide a suitable scaffold for cell growth and tissue regeneration. They can create scaffolds for various tissues such as bone, cartilage, skin, and nerves. The high surface area of fibers and tunable pore size enhances cell attachment, proliferation, and differentiation, promoting tissue regeneration.

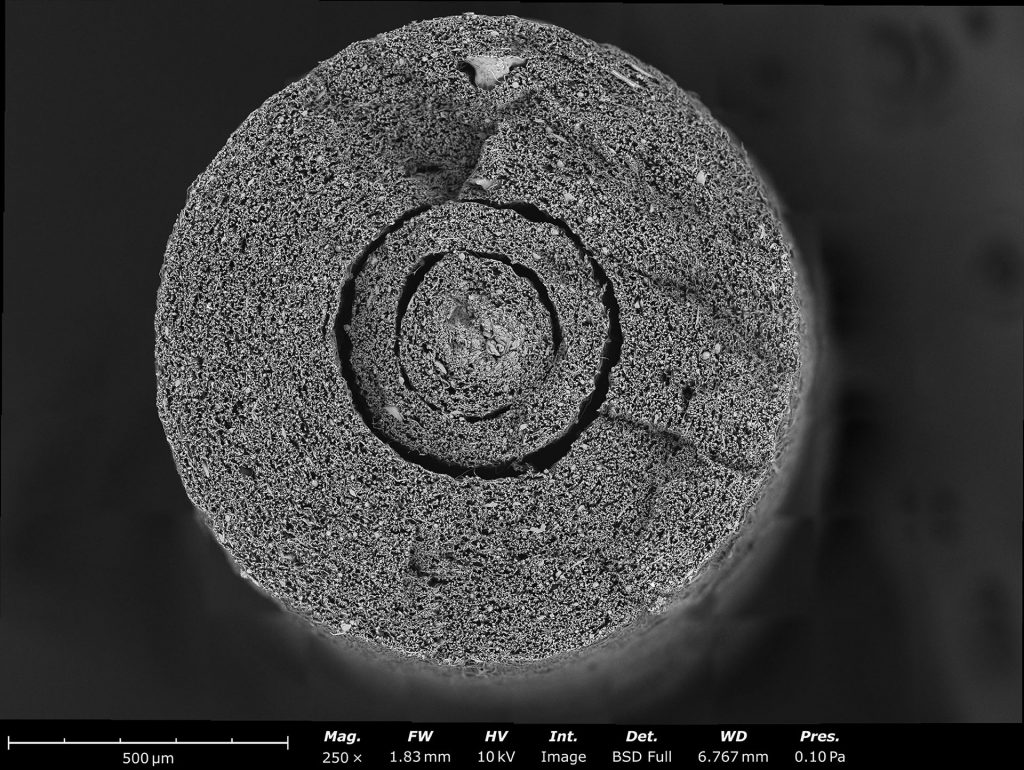

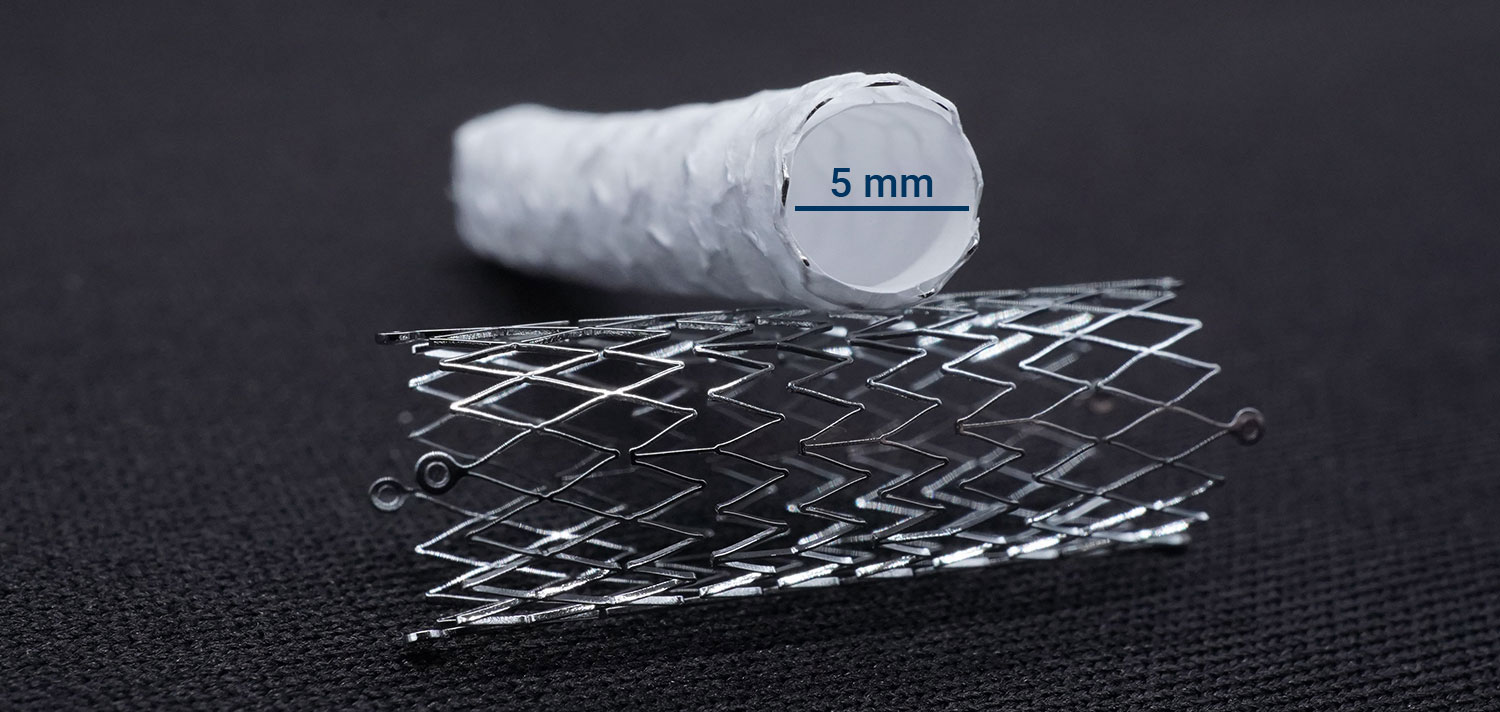

Additionally, combining technologies within the nanofibrous structures, such as drug-eluting capability, can help with regeneration by preventing unwanted cellular behavior like restenosis or infection. Tunable morphology and structure of the fibrous materials allow for tailored cell growth and support, such as aligned nanofibers for brain tissue or nerve conduits that help guide the natural axonal alignment and typically promote faster and more effective nerve regeneration.

Implantable Devices and Biocompatible Materials

Electrospun fibers can be used to fabricate medical materials like surgical sutures and meshes with improved mechanical properties and biocompatibility. These nanofiber-based materials can reduce inflammation, minimize scarring, and promote better tissue integration compared to traditional materials. Electrospun nanofibers, or microfibers, can also be used to coat implants to improve their biocompatibility and interaction with surrounding tissues. These coatings can enhance implant integration, reduce inflammation, and prevent infection. Additionally, the coatings can serve as drug delivery reservoirs to locally release therapeutic agents with specific elution profiles or extended-release capabilities.

Summary

Electrospinning has distinct applications in medical devices for its ability to produce nanoscale, and microscale, materials with unique properties suitable for diverse functionalities. These applications span tissue engineering, drug delivery, wound healing, implant coatings, and more, contributing to advancements in healthcare and improving patient outcomes.

References

[1] “Medical Devices.” World Health Organization, World Health Organization, www.who.int/health-topics/medical-devices