Particles are being used in different industries including pharmaceuticals, agriculture, food science, cosmetics, and filtration for a wide variety of applications. Several techniques are commonly used for particle fabrication including chemical precipitation, emulsification, spray drying, milling & grinding, and electrospraying. Each of these techniques has its advantages and disadvantages based on the application’s needs. While choosing a method for fabricating particles, multiple aspects including material compatibility, particle size, and shape, reliability, and uniformity, particle surface properties, and throughput, must be considered.

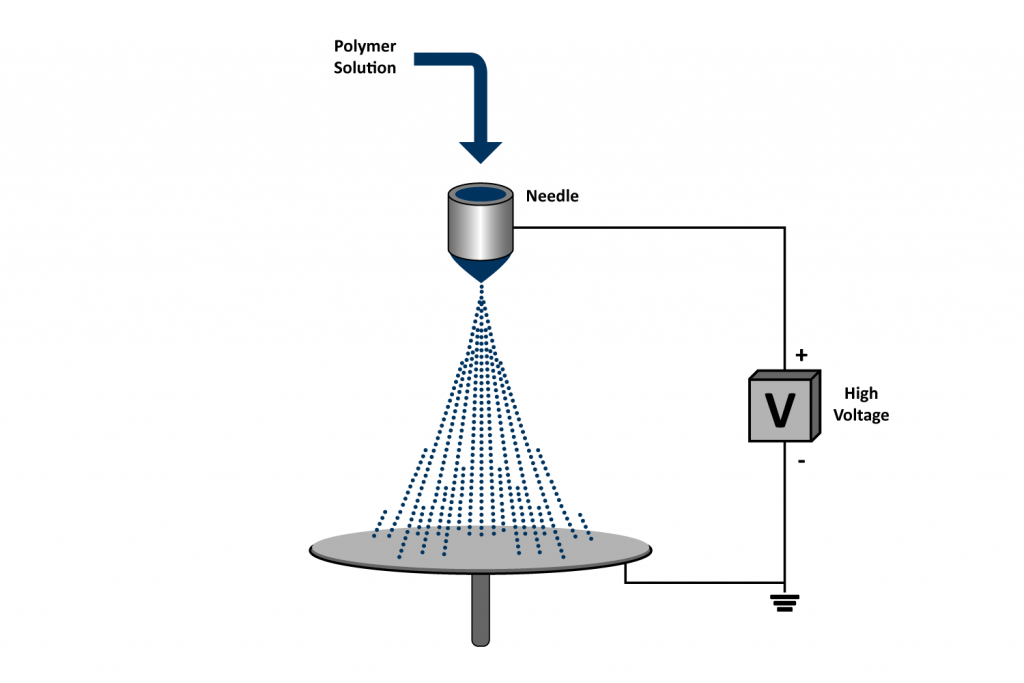

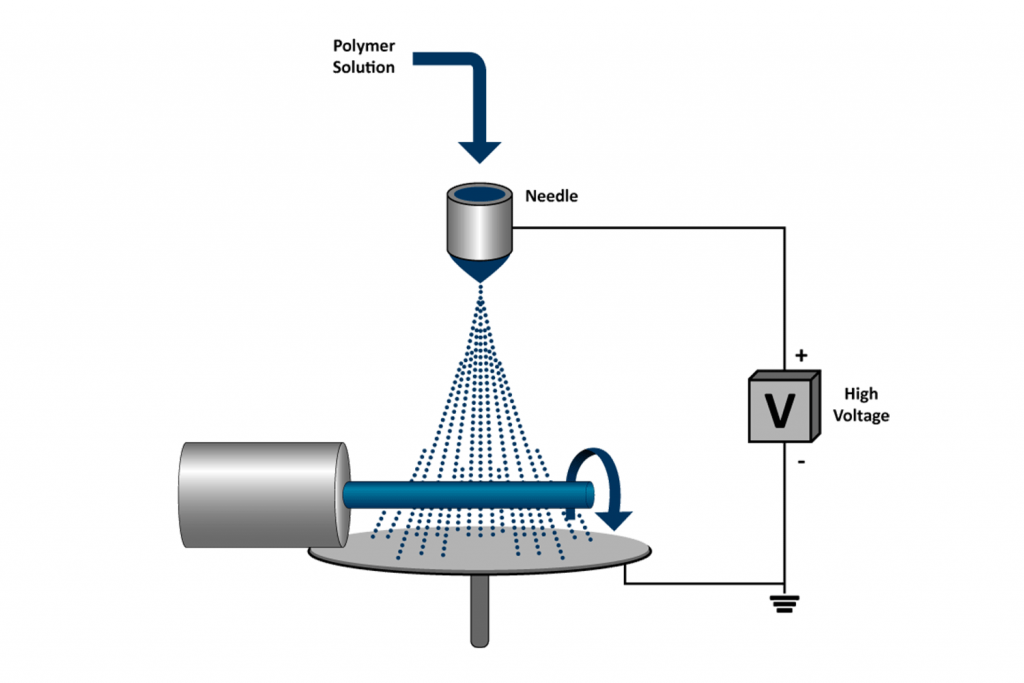

Electrospraying, also referred to as electrohydrodynamic atomization, is a voltage-driven technique where particles are typically made from a polymer solution, emulsion, or dispersion (Figure 1). It is a versatile technique that can be used to fabricate dry particles in a single step from many different materials at room temperature. The electrosprayed particles can be collected on a variety of collectors including flat plates, drums, and liquid baths. Electrospraying is a scalable technique that is amenable to tuning particle morphology and is easily combined with other techniques to develop complex structures. The control over solution properties and processing parameters optimization enables the fine-tuning of particle properties. In this article, we explore a few of the applications of electrosprayed particles.

Coating Medical Devices to Optimize Function

Electrospraying allows the fabrication of uniform thin coatings onto surgical implants with precise control of shape and dimension to modify surface properties. Uniform coatings can be achieved on larger devices like heart valves, smaller devices like coronary stents, and even irregular shapes like occlusion devices. Since electrospraying offers the advantage of processing different materials, these devices can be coated with generally recognized as safe (GRAS) FDA-approved materials like PCL, PLGA, PTFE, and collagen, along with metal nanoparticles, ceramics, or drugs of interest. Surface modification by electrosprayed particles offers several distinct advantages including controlled drug release, enhanced biocompatibility to reduce adverse immune responses and protect the coated device from corrosion or biofilm formation.1

Encapsulation of Active Pharmaceutical Ingredients (APIs) for Drug Delivery

APIs are crucial chemical components of pharmaceutical formulations as they provide the necessary therapeutic efficacy to treat medical conditions. APIs include small molecules, peptides, proteins, natural products, and synthetic compounds. Electrosprayed particles are beneficial in this field as they can impact these key properties in pharma:

- API Solubility: The solubility of poorly water-soluble or water-insoluble drugs can be enhanced by dispersing them in electrosprayed polymer particles. By controlling the electrospraying processing parameters, the crystallization behavior of API in particles can also be tuned to control the degree of crystallinity and solubility.2

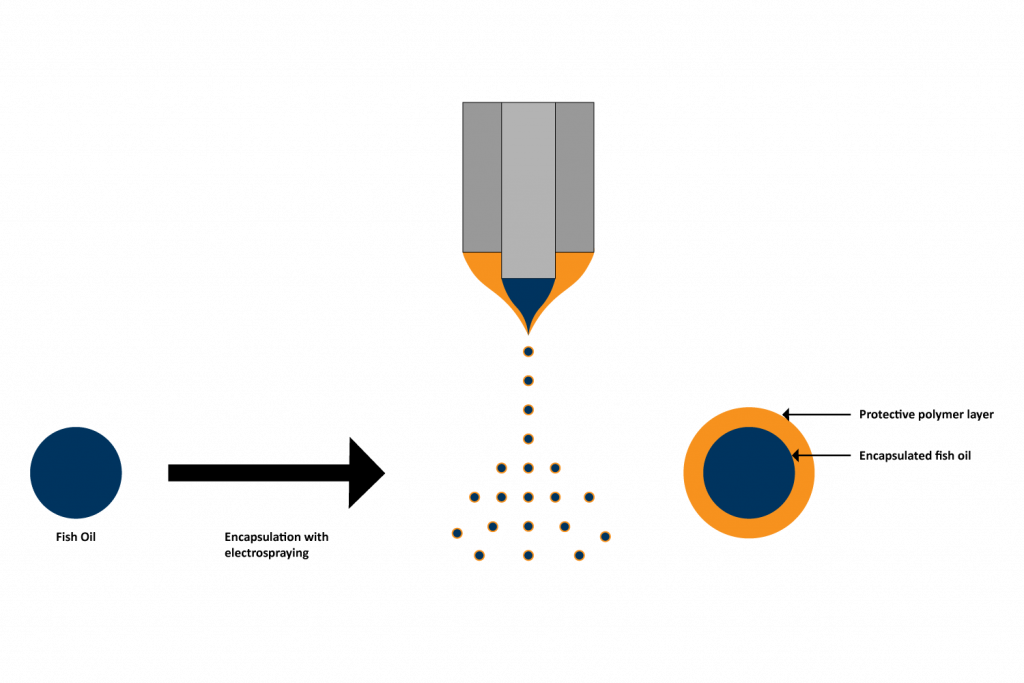

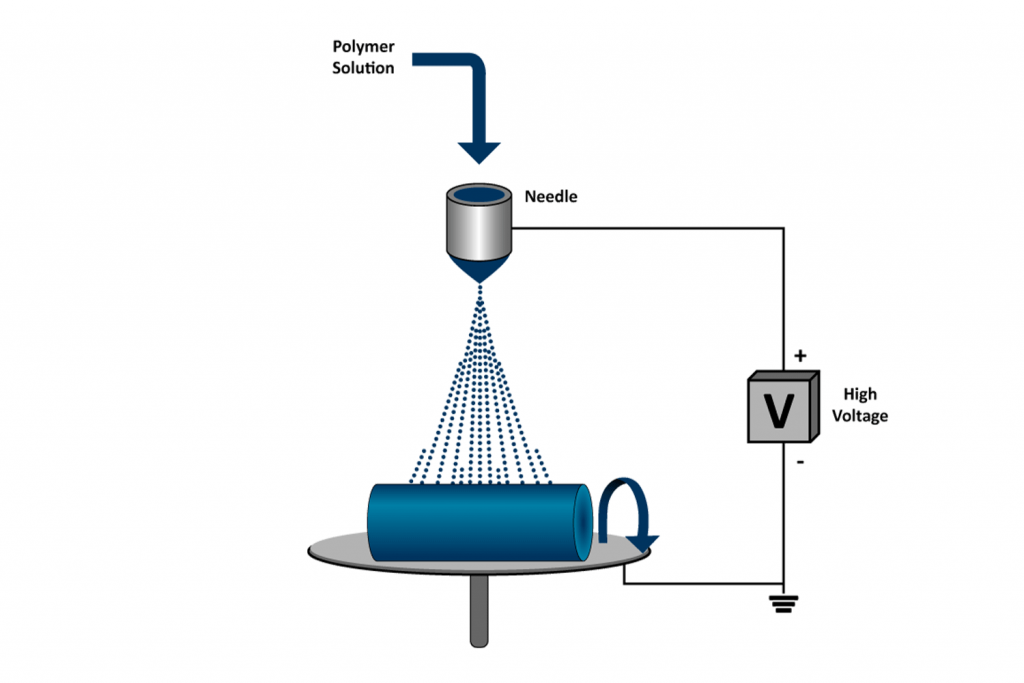

- Protection of APIs: APIs encapsulated in a particle are protected from different environments including moisture, light, oxidative stress, changes in pH, and enzymatic activity, that could lead to degradation or inactivation over time. The encapsulation process is illustrated in Figure 2. This allows for improved storage, transportation, and pharmacokinetics during the administration of the API in the electrosprayed particles. Ultimately, encapsulation in electrosprayed particles improves the stability and potency of the drug.3

- Biocompatibility and safety: Electrosprayed particles can be made from a wide variety of materials suitable for pharmaceutical use including biocompatible and generally recognized as safe (GRAS) FDA-approved polymers, and solvents. The ease of material selection gives the manufacturer of electrosprayed particles a plethora of options to generate biocompatible particles that do not cause adverse effects in patients.4 5

Nanoencapsulation of Food Ingredients

Volatile aromatic compounds, like essential oils, can be encapsulated in particles to enhance or mask flavors. These encapsulated compounds can then be used in food products to impart desirable aromas or flavors. One method is using coaxial electrospraying (Figure 2) to encapsulate the active ingredient, in the core of a polymeric particle thereby improving consumer satisfaction, and acceptability and making the product more appealable to the market.6

Encapsulation of Active Ingredients in Cosmetics

Active ingredients and other additives can be encapsulated by electrospraying to improve their stability and effectiveness. Using electrosprayed particles allows the use of pure active ingredients for immediate absorption and deeper penetration into the skin or targeted area.7 Additionally, electrospraying can enhance the texture, scent, and appearance of cosmetic products. Encapsulation makes cosmetics more effective and enjoyable to use.

Enhancing Filtration Devices

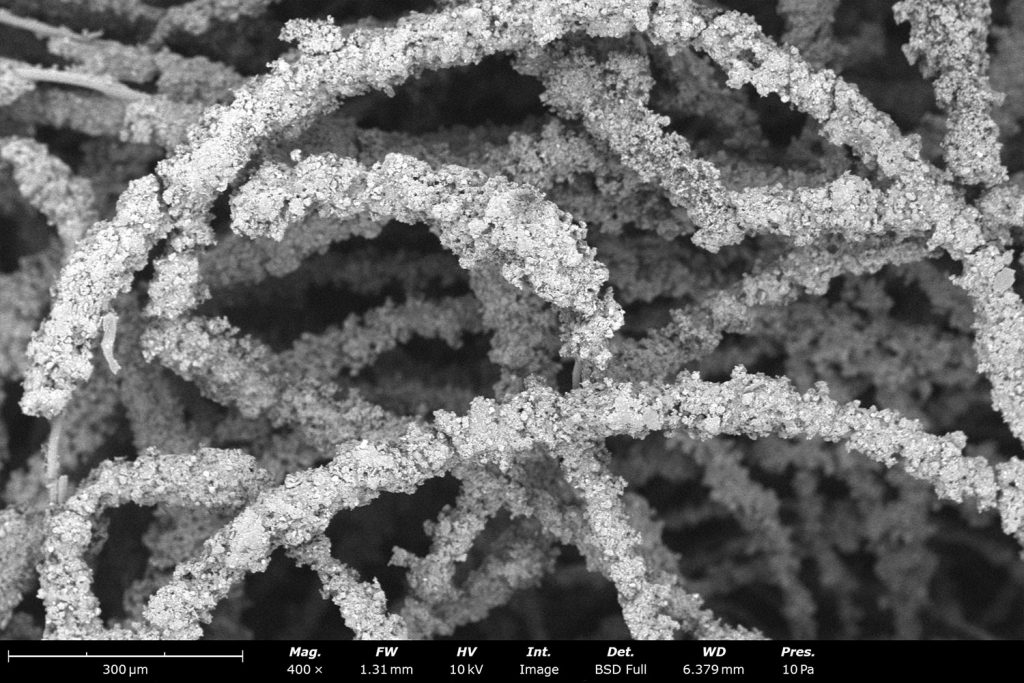

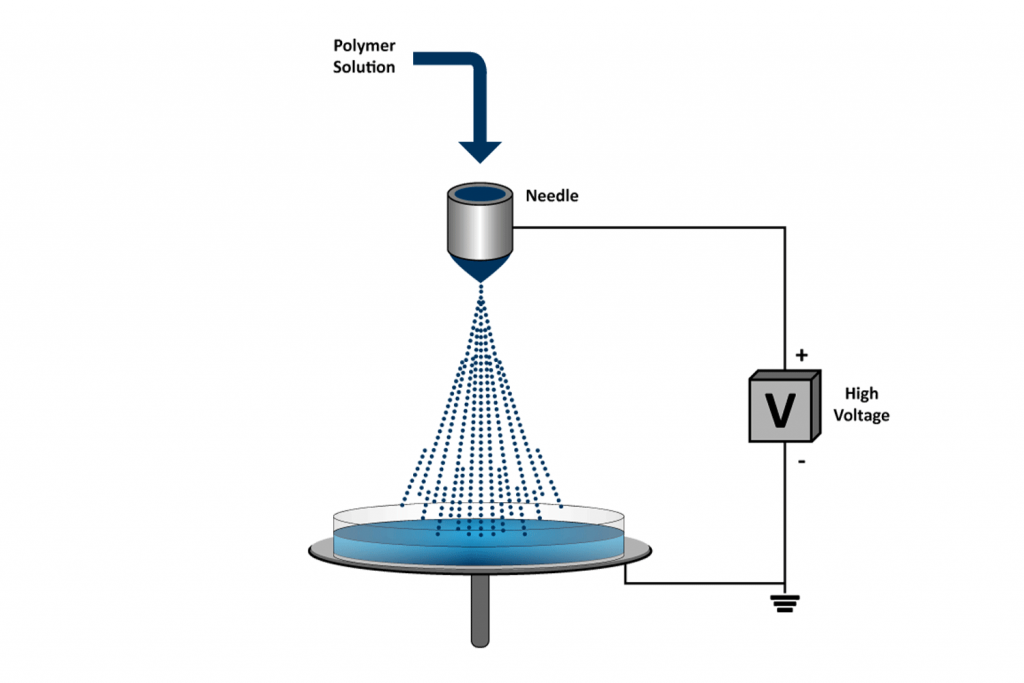

Existing filters can be coated using electrosprayed particles containing antimicrobial agents, activated carbon nanoparticles, or other additives of interest to remove pollutants or allergens.8 A key advantage of electrospraying on coating filtration media is maintaining the original overall structure of the fibers and not affecting the filter permeability (Figure 3). Electrosprayed particles can also be used to filter liquid media like blood to remove toxins and water for desalination or removing contaminants.

Conclusion

Electrosprayed nanoparticles have demonstrated versatile applications across various industries, including pharmaceuticals, medical devices, food, cosmetics, and filtration. These nanoparticles offer numerous advantages, such as tunable properties, precise control over morphology, and ease of material selection, making them invaluable in encapsulating active pharmaceutical ingredients, coating medical devices, enhancing, or masking flavors in food, formulating cosmetics, and improving filtration processes. By leveraging the unique characteristics of electrosprayed particles, industries can achieve enhanced product performance, efficiency, and consumer satisfaction while addressing specific application requirements and regulatory standards.

References

- EIS Analysis of Electro Sprayed Chitosan Membranes as Coating Over Magnesium in SBF as Used in Biomedical Applications ↩︎

- Nanostructured Valsartan Microparticles with Enhanced Bioavailability Produced by High-Throughput Electrohydrodynamic Room-Temperature Atomization ↩︎

- Bioavailability enhancement of nanostructured microparticles of carvedilol ↩︎

- Effect of solvent and additives on the electrospinnability of BSA solutions ↩︎

- Hydroxypropyl methylcellulose-based micro- and nanostructures for encapsulation of melanoidins: Effect of electrohydrodynamic processing variables on morphological and physicochemical properties ↩︎

- Physicochemical characterization and oxidative stability of fish oil-loaded electrosprayed capsules: Combined use of whey protein and carbohydrates as wall materials ↩︎

- Enhancing hygroscopic stability of agave fructans capsules obtained by electrospraying ↩︎

- Electrospun PCL Filtration Membranes Enhanced with an Electrosprayed Lignin Coating to Control Wettability and Anti-Bacterial Properties ↩︎