A scanning electron microscope (SEM) is a powerful scientific instrument used for high-resolution imaging and surface elemental analysis. They work by scanning a focused beam of electrons across the sample’s surface and detecting the resulting signals to create detailed images. SEMs provide value in a wide range of applications including materials science, biology, nanotechnology, forensics, geology, quality control, failure analysis, and particle analysis.

When it comes time to purchase an SEM, the overall cost can vary depending upon the specific configuration and optional accessories. Additionally, there are costs associated with installation, training, maintenance, and ongoing operational expenses. A general overview of these key factors is explained below.

What factors affect the price of an SEM?

SEMs are complex and sophisticated instruments, which makes them quite expensive. Typically, new SEMs cost anywhere from $50,000 to over $1,000,000. The cost of scanning electron microscopes (SEMs) can vary significantly depending on several factors, including the resolution, form factor, electron source, detectors, sample holders, and software.

Resolution

A large component of the cost of an SEM comes down to resolution. SEM resolution ranges from 15 nm for entry-level models down to <1 nm found in higher-end instruments. The resolution limit is determined by multiple components that make up the beam formation system. These include the electron gun, the accelerating voltage, and the lens configuration throughout the column which help to focus the beam of electrons onto the sample surface.

Form factor

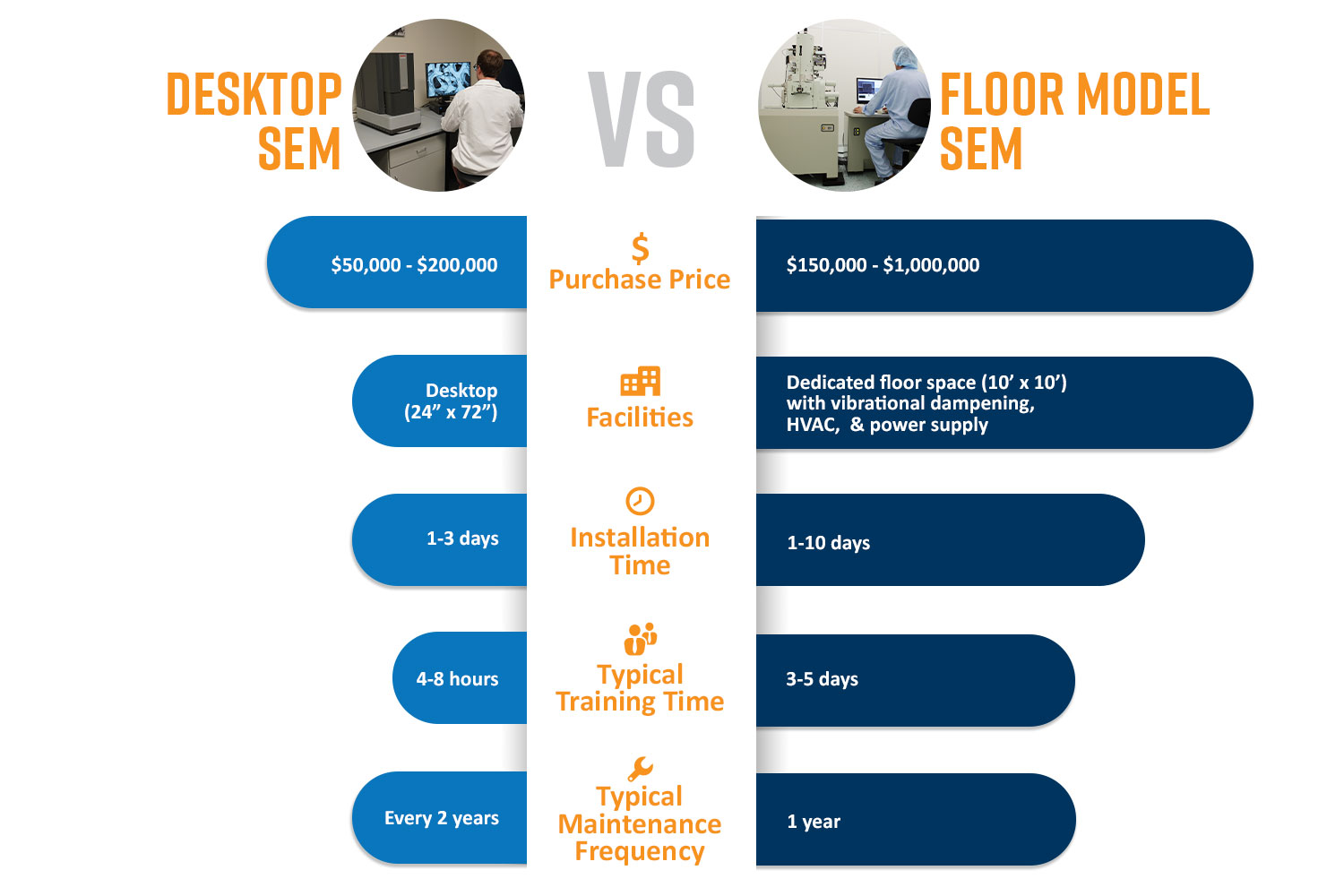

The physical footprint of the SEM is going to affect the cost in multiple ways. The two types of form factors are floor model SEMs and desktop SEMs. Floor models allow for higher resolution and specialized applications but are significantly more expensive as they require specialized facilities with vibrational isolation, a high-power supply, more frequent maintenance, and skilled operators. On the other hand, desktop (sometimes referred to as benchtop or tabletop) SEMs are well-suited for conventional laboratory environments and a wide range of applications. They are also significantly less expensive to purchase and maintain.

Configuration

Higher-end SEMs can be configured with multiple electron beams, such as a multi-beam setup for high-throughput parallel imaging, or with an ion beam source for performing focused ion beam (FIB) milling of samples. This adds substantial cost because the placement of detectors and column configuration need to be carefully optimized. Additional data processing software and hardware will also be needed.

Electron source

There are three common types of electron sources used in SEMs. Tungsten hairpin emitters have the lowest cost of ownership but also provide the lowest resolution. Solid-state hexaboride crystals (CeB6 or LaB6) offer a significantly higher resolution at a modest increase in price. Schottky field emission guns (FEGs) can reach the highest resolutions but also are the most expensive option.

Detectors

Having additional detectors installed on an SEM will increase its cost and capabilities. Most SEM models will come with a standard detector, and you will pay extra for additional detectors. The most common types of detectors found in an SEM include the secondary electron detector (SED), backscatter electron detector (BSD), and the energy-dispersive X-ray spectroscopy (EDS) detector. Additional detectors may include wavelength-dispersive X-ray spectroscopy (WDS) detectors, electron backscatter diffraction detectors (EBSD), and cathodoluminescence (CL) detectors.

Sample holder

The size, complexity, and features of the sample stage will impact the overall purchase price of an SEM system. Larger stages can hold multiple pin stubs or hold larger bulk samples. The type of stage movement controls, including lateral X and Y, Z movement (height), tilt, and rotation as well as the mechanism (e.g., motorized or manual) will incur additional costs. Additional costs can also come from adding stage inserts that accommodate specifically shaped samples such as filters/membranes and resin-embedded samples. There are also dedicated sample holders that enable temperature control (e.g., heating and cooling) and additional measurements to be made, such as tensile testing or current-voltage response, while imaging a sample in the SEM.

Software

Modern SEMs will come with standard user interface software that allows one to control many of the microscope functions like stage control, beam settings, magnification, and image acquisition. Additional software to automate SEM workflows, such as through automated data collection and image analysis, will increase the overall price and value of the SEM instrument.

Additional features

Additional features may or may not be included in the base model of a particular SEM instrument. These can include low vacuum mode (or charge reduction mode), BSD and SED image signal mixing, compatibility with an inert atmosphere environment (such as a glovebox filled with Argon gas for working with volatile samples), or compatibility with scripting languages to customize workflows.

Cost of Ownership

The cost of ownership encompasses installation, training, maintenance, and operational expenses. In general, floor model SEMs will have higher costs in all four categories due to their size, higher power consumption, and complexity. Organizations considering owning a floor model SEM should also consider the cost of facility upgrades to house the instrument and the possibility of hiring new staff to effectively run the instrument. Because of frequent issues with highly complex floor model SEMs, service contracts are often purchased to cover frequent issues that come up.

Desktop SEMs are known for their minimal cost of ownership as they take about one day to install, require very little maintenance aside from electron source changes, and are easier to learn meaning that non-specialists can effectively use them.

Takeaways

Investing in an SEM involves significant costs, including the initial purchase, installation, maintenance, and operational expenses. The biggest factors affecting the cost are the resolution and configuration. Cost of ownership is significantly higher for floor-model SEMs compared to desktop models. Continued innovation has allowed desktop SEMs to achieve comparable performance to floor-model SEMs, making in-house SEM more accessible to many organizations.

It’s recommended to contact a technical expert from authorized distributors to get accurate and up-to-date pricing information for specific models that meet your requirements. They can provide detailed quotations and discuss additional costs associated with the purchase, installation, and maintenance of the SEM.