Recent advancements in food science research represent a dynamic frontier with profound implications for our global food systems. Breakthroughs in food preservation and packaging technology will contribute to extending shelf life, reducing waste, and increasing safety. Researchers in Dr. Lamin Kassama’s Food Engineering lab at Alabama A&M University are exploring the potential of using electrospun polymers to develop “active” polymeric films for food packaging.

What are “active” films?

‘Active’ films, are food packaging films that are designed to have properties that actively protect the food products from spoilage. ‘Active’ packaging materials often utilize one or more of the following food preservation measures: antioxidants, antimicrobials, ethylene scavengers, and oxygen and/or CO2 regulation, among many others.

A significant portion of the work in Dr. Kassama’s Food Engineering lab is focused on novel polymeric nanofiber and nanoparticle formulations to develop “active” films. Nanofibers and nanoparticles are particularly advantageous for applications like food packaging because of their unique properties, which include a high surface-area-to-volume ratio, high porosity, superior tensile properties, chemical stability, and high encapsulation efficiency which lend well for use as ‘active’ films. The group uses electrospinning and electrospraying techniques to fabricate the nanofibers and nanoparticles.

“Active” food packaging development at Alabama A&M University

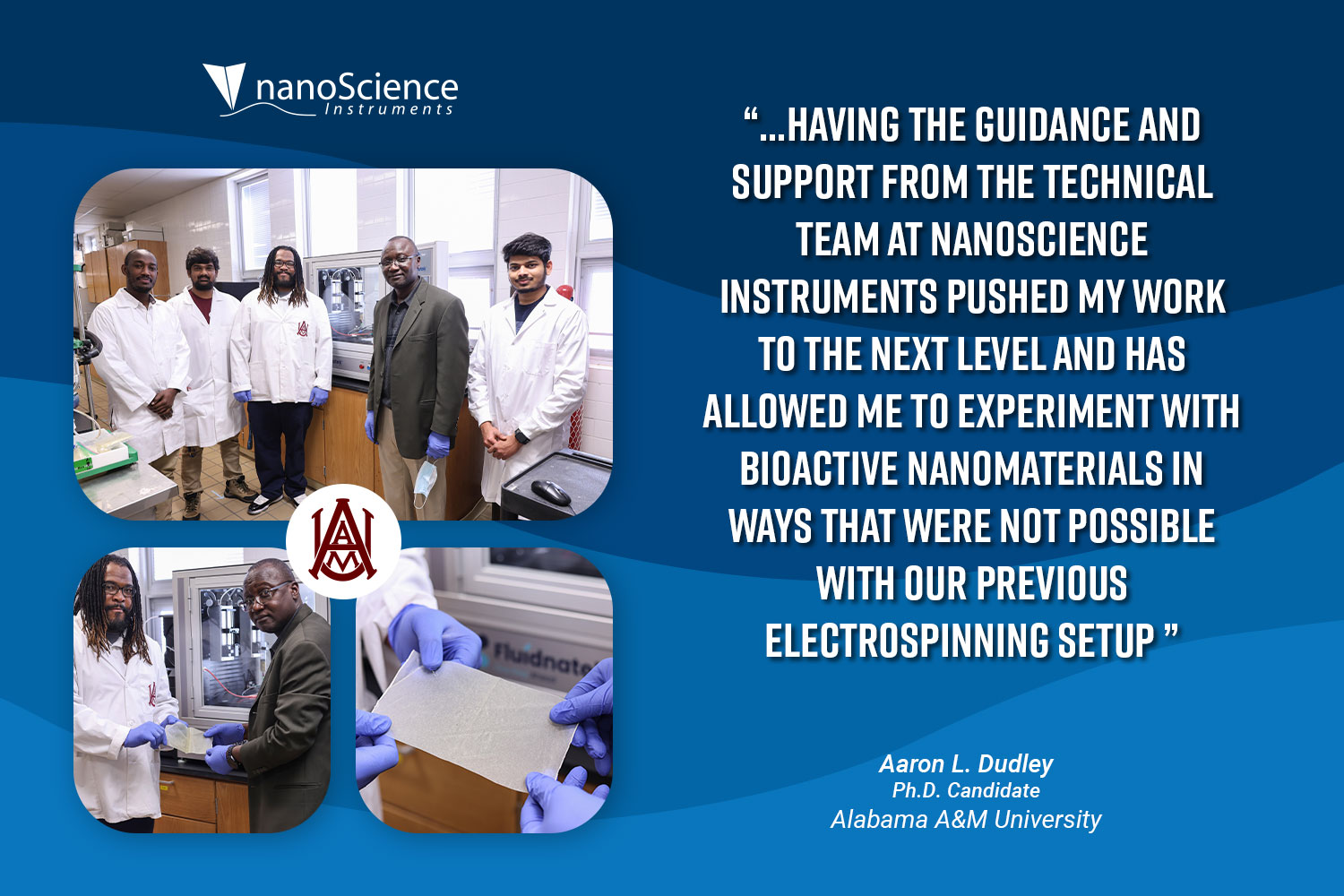

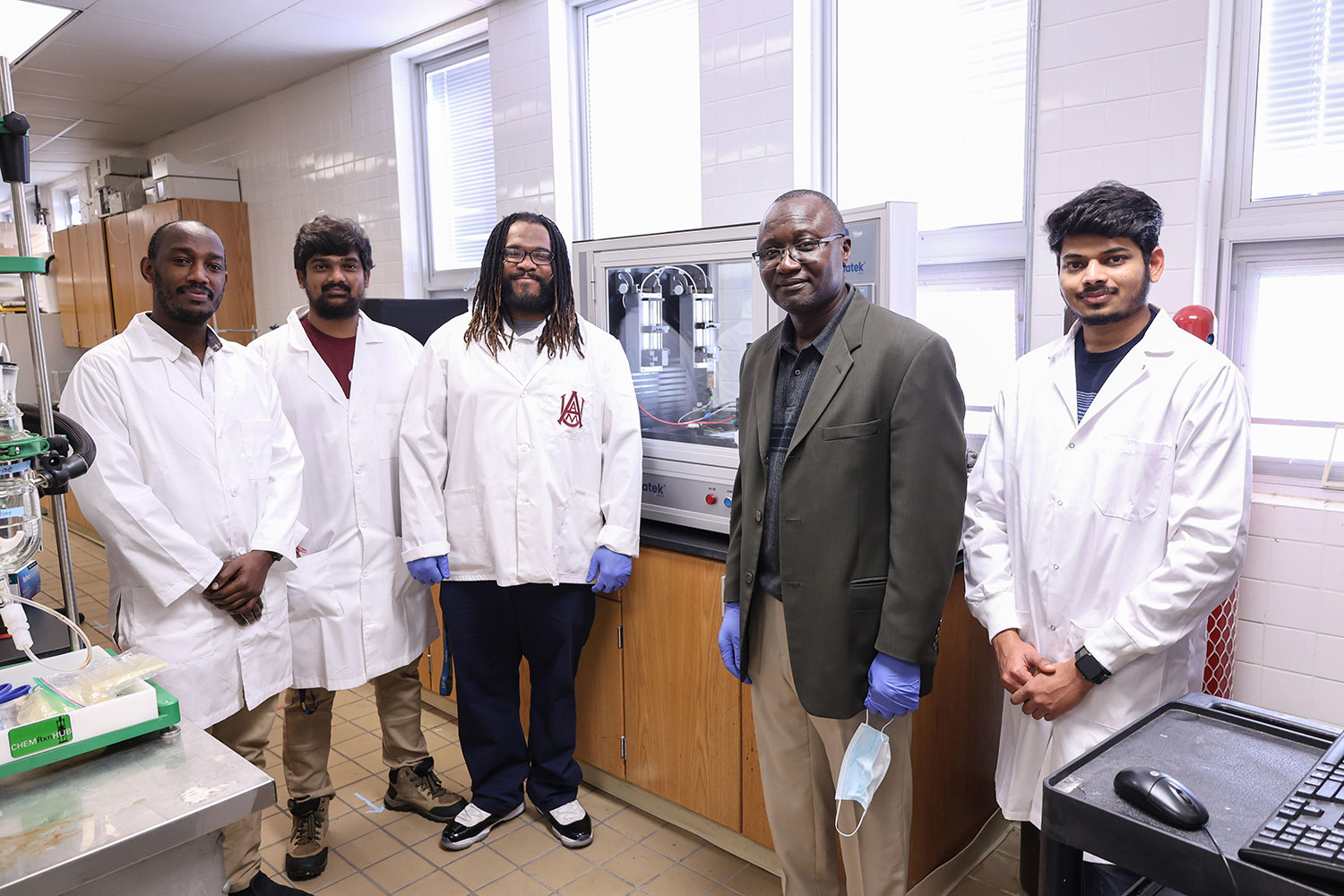

Aaron L. Dudley, a PhD candidate in Dr. Kassama’s laboratory, and his colleagues are leading the effort to develop “active” packaging. During his former career as a food development scientist, Aaron became familiar with the intricacies of the nanoscale interactions that dictate the quality, appearance, sensory characteristics, and shelf-life of food products. Aaron’s current work focuses on incorporating bioactive molecules into nanofibrous materials to study their behavior and capitalize on the many beneficial properties for food preservation. The specific formulation that he has developed utilizes hemp extracts derived from plants grown at their university’s research station. These have been shown to have favorable bioactive characteristics for extending food shelf life, including antioxidative and antimicrobial properties [1,2]. By manipulating material properties at the nanoscale, he can engineer materials that have ideal physical properties such as porosity, gas permeability, and flexibility, and will also efficiently deliver these bioactive compounds.

Why use Electrospinning to Fabricate Packaging Films?

Electrospinning is a room-temperature process that generates nanofibers by ejecting a polymer solution through an emitter into a high-voltage electric field. The fabricated fibers are then collected on an oppositely charged collector. Fibers can be fabricated from a wide range of materials, including polymers (natural, synthetic, and semi-synthetic), composites, ceramics, and metallic elements. Essentially, electrospinning provides a relatively simple means to produce novel materials with carefully tuned properties that suit the needs of developing packaging films.

The Fluidnatek Difference: Quality, Safety, and Process Control

Aaron and his colleagues were initially using a custom-built electrospinning system to fabricate the nanofibers.

“To get acclimated to electrospinning processes, we were using a preliminary, or more rudimentary, custom-built system at first. We only had an electrical source, drum collector, and a simple pump to feed the biopolymer solution.”

However, they quickly learned that to develop an optimal formulation for antimicrobial and antioxidant-loaded films, they needed to develop a repeatable and consistent fabrication process. Iterating through a process several times on a custom-built machine would be not only time-consuming but came with safety concerns as well.

Custom-built, or “home-built,” systems are often riddled with safety risks, including electrical and fire hazards due to high voltage power supplies, and possible respiratory issues due to lack of ventilation for volatile solvent fumes. Taking these and other factors into consideration, the group soon realized that their custom-built system was an insufficient solution for the level of precision that they needed for their rigorous research.

After a careful vetting process, they chose to invest in the Fluidnatek LE-50 professional-grade electrospinning and electrospraying system.

“As we were looking through the different equipment options, the Fluidnatek systems offered by Nanoscience Instruments rose to the top because of the quality of the equipment, and our positive interactions with the electrospinning team.”

One benefit of choosing the Fluidnatek LE-50 was the significant amount of local support that is readily available. Aaron mentioned that their decision to acquire the Fluidnatek LE-50 system was made easier by his interactions with Dr. Francisco J. Chaparro, Senior Product Manager at Nanoscience Instruments.

“I have had a very positive experience working with the company, especially Francisco, who came to our lab for the installation and training. He was there with us every step of the way, showing us the ins and outs of electrospinning.”

International recognition:

In 2023, Aaron entered a worldwide competition for the Institute of Food Technologists (IFT), the scientific body of the food industry. He was awarded 3rd place overall for his oral presentation in a global competition that drew hundreds of submissions. His presentation detailing the novel developments in material engineering for food packaging applications was unique among the other presentations.

“The electrospinning work stood out as it is still an emerging technique in food science and food engineering… Working with the Fluidnatek equipment for sample development, and having the guidance and support from the technical team at Nanoscience Instruments pushed my work to the next level and has allowed me to experiment with bioactive nanomaterials in ways that were not possible with our previous electrospinning setup.”

The future of food packaging

In addition to the antioxidative, antimicrobial properties of the packaging film, the group aims to carry out more extensive characterization using oxygen permeability tests, water vapor transmission rate studies, tensile strength, and durability experiments. Aaron looks to the future with hope for this growing field of research and expects that it will transform current food packaging practices.

“I think in a few years, there is a real promise that nanofiber materials could be used in packaging materials for food, to reduce the microbial load in the food items and extend their shelf life”.

We are looking forward to seeing how the implementation of these electrospun materials drives advancement in the food industry.

References:

[1] A. L. Dudley, L. M. Kassama, A. Jackson-Davis, X. Kuang, and E. Cebert, “Antimicrobial and Antioxidative Activity of Ethanolic Extract from Two Hemp (<i>Cannabis sativa</i> L) Cultivars Grown in Northern Alabama.,” 2022 Houston, Texas July 17-20, 2022, Jan. 2022, doi: 10.13031/aim.202200476. Available: https://doi.org/10.13031/aim.202200476

[2] A. L. Dudley, L. S. Kassama, A. Jackson-Davis, J. Shin, X. Zhang, and E. Cebert, “Electrospinning of Northern Alabama Grown Hemp Extract in PVA to Develop an Active Packaging Film,” 2023 ASABE Annual International Meeting, Jan. 2023, doi: 10.13031/aim.202300754. Available: https://doi.org/10.13031/aim.202300754