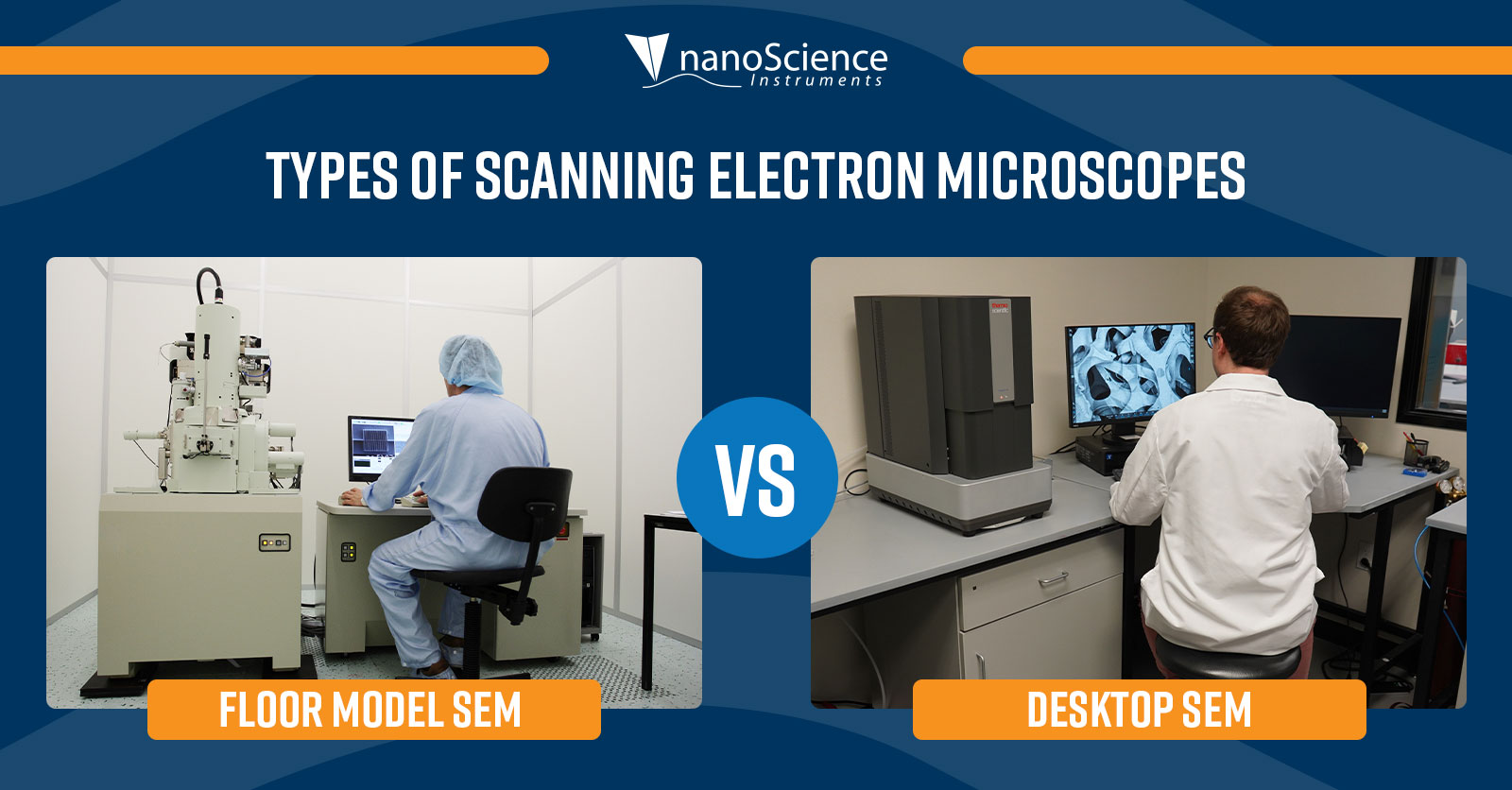

In the realms of scientific industry and research, scanning electron microscopes are among the most common imaging tools for studying the microstructures of materials. Microscopists employ SEMs to greatly expand their characterization abilities, gaining meaningful insight into a sample’s elemental composition and morphological properties. SEMs come in two varieties differentiated by form factor with the larger of the two commonly called standing floor models or full-size models and the smaller desktop models.

Floor model SEMs trace their roots back to the emergent days of electron microscopy. As their name suggests, they occupy a large volume of space extending from the ground to approximately the height of a standing lamp (about 5 ft). The smaller SEM is a more recent miniaturization and uses synonymous descriptors – desktop, benchtop, or tabletop SEM – to emphasize the dramatic shift in size from its progenitor. Beyond physical footprint, the essential differences between floor model and desktop SEMs are encompassed by the available detectors, ease of use, infrastructure requirements, and price point.

Detectors:

Floor model SEMs have much larger electron columns than desktop variations. Larger columns allow for the inclusion of more apertures and condenser lenses, creating flexibility to manipulate the electron beam for specific analyses. Floor models also have the space to add numerous detectors for different applications. These applications may involve EDS (energy dispersive x-ray spectroscopy), WDS (wave dispersive spectroscopy), CL (cathodoluminescence), EBSD (electron backscatter diffraction) and XRF (X-ray fluorescence), and the types of detectors corresponding to these applications can be swapped between different floor model systems regardless of manufacturer or brand. Additionally, floor models offer the ability to integrate FIB (focused ion beam) for nanofabrication applications. The vast range of available options makes it so that a floor model can be customized to fulfill all kinds of research cases.

In contrast to the floor model SEM, desktop SEMs do not offer the same level of customization. The compact design limits the number of detectors that can fit into the system, demanding a level of simplicity and efficiency of design. Together, the backscattered electron detector (BSD), secondary electron detector (SED), and EDS detector perform most of the tasks an SEM is used for and thus are the detectors used on desktop SEMs. These three detectors offer complimentary data, enabling desktop SEMs to efficiently tackle a very broad range of applications.

Ease of use:

Floor models are more complex systems and present a steep learning curve for new users. While the ability to customize and control every aspect of this system can be a benefit, the volume of options adds complexities that are challenging for an inexperienced user to navigate. Therefore, most floor model SEMs require extensive training and thus necessitate a dedicated technician to prepare samples, operate the SEM, and maintain its functionality.

Improving the accessibility of SEMs was one of the motivations for the creation of desktop SEMs. They are designed to allow many users to be trained quickly, removing the requirement for a dedicated operator. Operating a desktop SEM is simple and a user with little to no experience can learn to acquire high-quality images in a short amount of time.

Space requirements:

Floor model SEMs require a large amount of space to house the system and other components needed to keep it operational. Certain models even require specialized foundations and environmental isolation for proper functionality. Eliminating these requirements was an additional driving force behind the creation of desktop SEMs. A compact design works to improve the system’s tolerance to vibrations and electromagnetic fields. This environmental insensitivity allows many desktop SEMs to be placed on desks, lab benches, or even cubicles without requiring anything more than a flat, sturdy surface.

Flexibility:

Floor model SEMs are generally housed in microscopy facilities and are managed and operated by dedicated experts. Investigators who need to use the SEM will have to take their samples to these facilities and get assistance from the experts to get the information that they need. This means that turnaround time for much needed data can be anywhere from hours to weeks. However, desktop SEMs can be housed directly in the laboratory of the investigator and can be used as desired.

Overall cost:

In general, floor model SEMs are more expensive than desktop units due mostly to their size and complexities. Those in the process of acquiring SEMs must also consider the cost of custom-built facilities that can provide the appropriate environment, instrument maintenance, and trained experts needed to operate and maintain the system. The cost to acquire and maintain such a complex instrument is substantial and, in many cases, can be difficult to justify.

Desktop SEMs cost a small fraction of the price of a floor model to acquire and maintain. They do not require the additional costs of a special facility or expert operators. The benefits the system provides at such a cost are significant, making it an attractive option for many applications.

Conclusion:

While both types of scanning electron microscopes bring versatile analytical abilities to the lab, microscopists must carefully weigh the differentiating parameters between the two forms when choosing an instrument. Although the nature of the research that the SEM is applied to may affect this choice, the detector capacities, accessibility and ease of use, infrastructure limitations, and price point are more crucial aspects to consider.