In this Electrospinning edition of our newsletter, we introduce you to the unique technology behind Fluidnatek’s new LE-500 BioDevice Electrospinning & Electrospraying system and provide a wealth of new resources including webinars, customer stories, white papers, blogs and more! Follow us on LinkedIn for more frequent updates on Nanoscience events, application resources, and news.

NEWS & UPDATES

Introducing the LE-500 BioDevice

Electrospinning & Electrospraying System

Efficiently Coat Complex Medical Devices and 3D Collectors

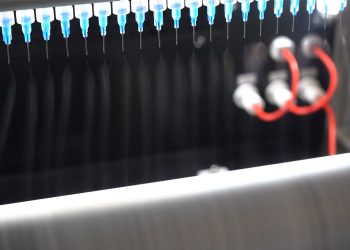

The LE-500 BioDevice is the first electrospinning machine with integration of a collaborative robot (CoBot) arm inside its chamber. This unique feature offers an unparalleled ability to manipulate the collector or emitter in 3D space, enabling multi-step processing and variable deposition angle to coat complex medical implants, medical devices, and 3D parts.

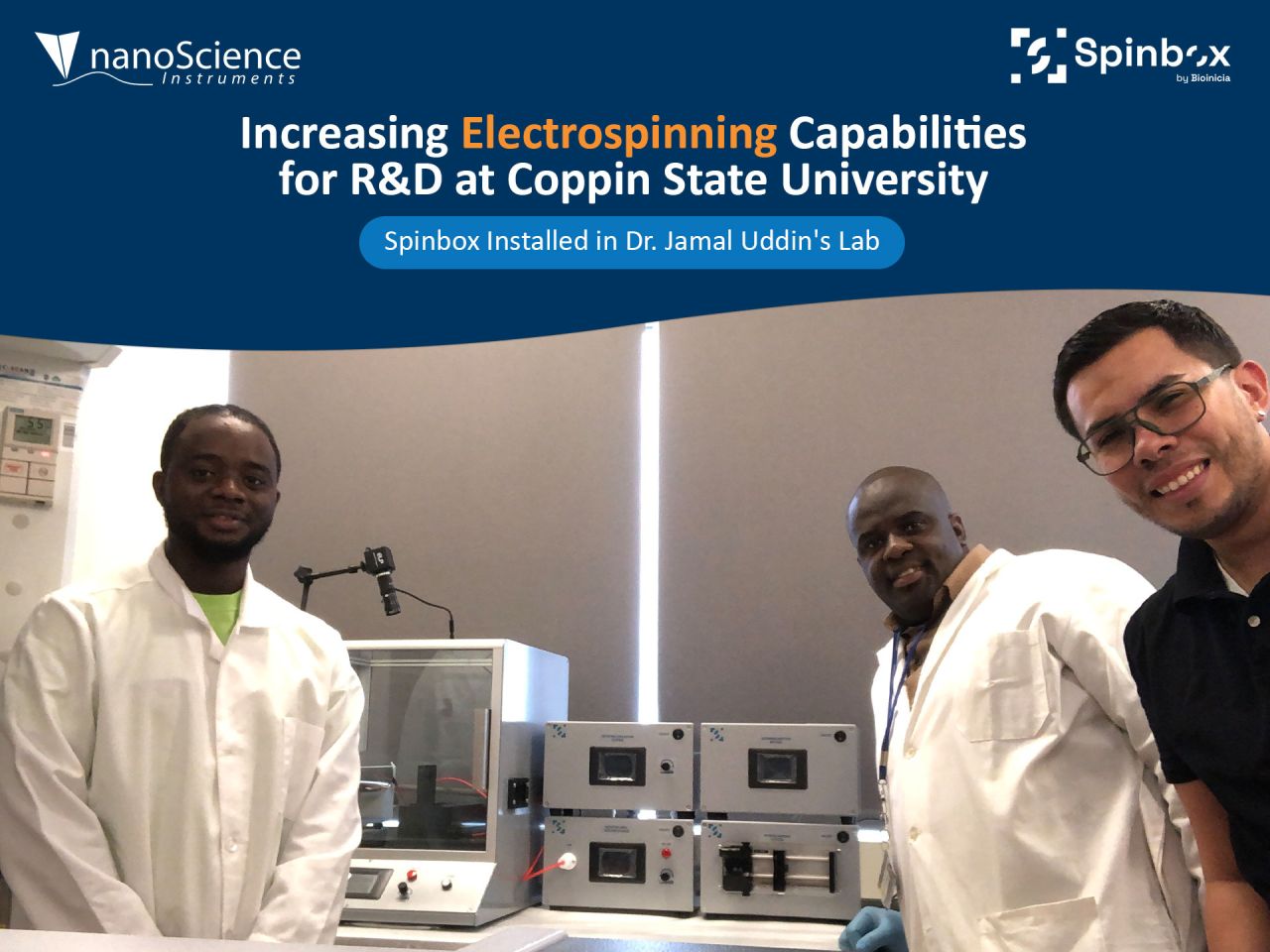

FEATURED STORY

Congratulations to Dr. Jamal Uddin, the founder of the Center for Nanotechnology at Coppin State University, who recently added an advanced electrospinning system to his lab! The new Spinbox electrospinning and electrospraying system will expand the center’s R&D capabilities and enhance its educational endeavors.

We look forward to seeing how the Spinbox empowers the group at Coppin State to explore new frontiers in nanomaterial fabrication and share the power of electrospinning with students in their community!

WEBINARS

Electrospinning Innovations in Commercial Medical Devices

Join us for an insightful webinar spotlighting the integration of electrospinning and electrospun materials in today’s medical landscape. We will explore how this cutting-edge technology drives advancements across diverse commercial …

In this insightful webinar, Dr. Hannah A. Lacy will explore how electrospinning drives advancements across diverse commercial healthcare applications, including wound healing and dressings, drug delivery systems for precise treatments, tissue engineering and regenerative medicine, implantable devices, and biocompatible materials that are reshaping today’s medical landscape.

Elastin Based Nanofibers for Advanced Wound Care: Innovation Driven by Electrospinning

The extracellular matrix (ECM) is a network of structural proteins that support cells and enhance tissue mechanical properties. Elastin, a crucial ECM protein, gives tissues elasticity and resilience. However, it …

Electrospinning Scalability of BioTextiles for Tissue Engineering & Medical Applications

Electrospinning is a rapidly growing method for producing nonwoven materials that mimic the extracellular matrix of the in vivo environment. This technique allows for the use of environmentally friendly polymers and the …

CONFERENCE CORNER

Where you will find us next year:

Medical Design & Manufacturing (MD&M) West

February 6-8, 2024 | Anaheim, CA

Visit us in Booth #547 to learn about how electrospun nanofibers and electrosprayed nanoparticles are being used to transform commercial medical devices. We will showcase several emerging healthcare solutions that benefit from the use of electrospun and electrosprayed nanomaterials, including stents coated with antithrombotic APIs, tissue scaffolds with tunable properties that encourage cell migration and proliferation, coated nanofibers for drug delivery applications, and more!

Don’t miss our Technical Presentation during the Drug Delivery & Novel Processing of Medical Polymers session:

Dr. Francisco J. Chaparro will discuss how electrospinning and electrospraying have been used to develop functional nanomaterials for use in a wide variety of biomedical and clinical applications. Join the talk to learn more about API-encapsulated nanoparticles, API-incorporated porous nanofibers, and other emerging technologies that are fabricated or enhanced by electrospinning.

245th ElectroChemical Society (ECS) Meeting

May 26-30, 2024 | San Francisco, CA

We look forward to showcasing our portfolio of solutions for electrochemistry, battery, and fuel cell research at next year’s ECS meeting! In the meantime, we invite you to explore our range of instruments that support the fabrication and characterization of electrodes, sensors, battery separators, and more!

SERVICE & SUPPORT

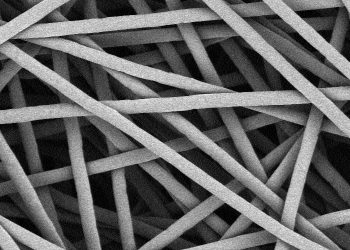

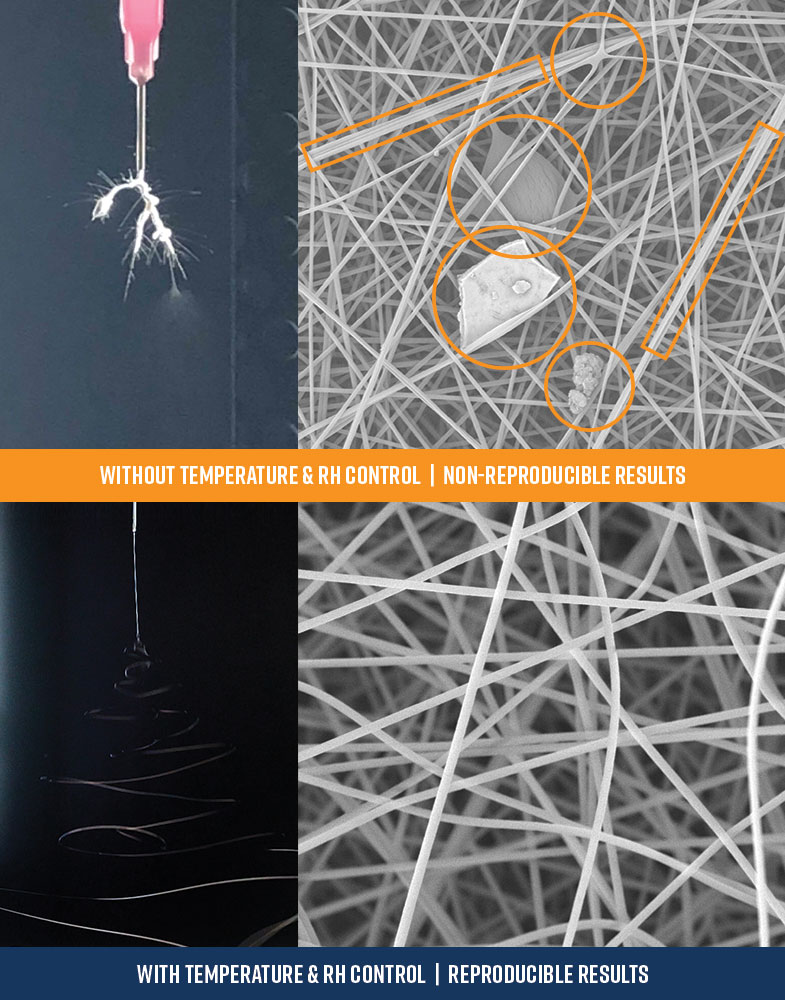

Precise regulation of Temperature and Relative Humidity (RH) in the processing chamber while electrospinning and electrospraying are prerequisites to reproducible, defect-free fabrication of nanofibers and nanoparticles.

Our new web pages help outline the key differences between two common types of conditioning units for professional electrospinning and electrospraying systems: dehumidifying units (DHUs) and full environmental control units (ECUs). Fluidnatek has engineered their DHU and ECU to pair perfectly with their electrospinning and electrospraying equipment, providing maximum control over critical processing conditions.

We invite you to explore these new pages to learn more about the capabilities of Fluidnatek’s exclusive DHU and ECU, or reach out to our experts to discuss your requirements and production goals.

Consumables are now available on our Webstore!

We encourage you to explore the ‘Electrospinning Accessories’ page of our recently updated webstore to see the range of consumable components and assembly kits that are now available for purchase online. From needle assemblies to plugs and tubing, you can now restock at your convenience.

RECENT BLOGS

10 Reasons to Use Electrospinning

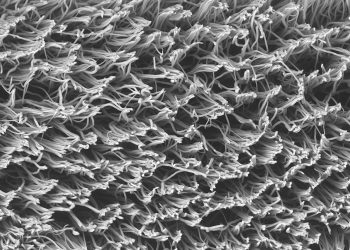

Electrospinning is a voltage-driven material fabrication process that can be used to produce micro to nano-scale fibers. The electrospinning process is a combination of interacting electric, hydrodynamic, and surface tension …

8 Reasons to Buy a Commercial Electrospinning or Electrospraying System

Electrospinning and electrospraying are electrohydrodynamic processes wherein a polymer solution is used to fabricate fibers or particles, respectively. In the most basic setup, a polymer solution is loaded into a …

7 Factors to Consider While Buying an Electrospinning Machine

Electrospinning is a versatile nanofiber fabrication technique wherein a polymer solution is charged and ejected from a spinneret under a high-voltage electric field. As the polymer is ejected, the solvent …

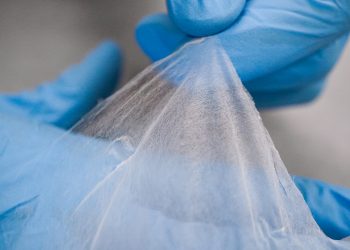

7 Recent Advancements in Nanofiber Applications

Nanofibers are ultrafine fibers with diameters typically ranging from a few nanometers (nm) to a few hundred nanometers. To put this in perspective, a nanometer is one billionth of a …

Empowering Nanofibers: Enhancing Usability and Overcoming Production Challenges

Nanofibers, or fibers with diameters on the scale of 10-9 meters, exhibit unique properties, differing significantly from the properties of the bulk materials. These include a large surface area to …

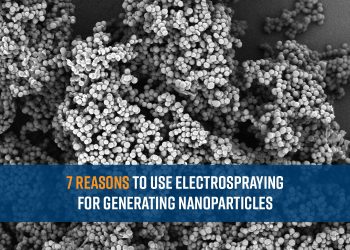

7 Reasons to Use Electrospraying as a Reproducible Method to Generate Nanoparticles

Particles are used daily in a wide variety of applications including coating surfaces and encapsulation of active ingredients. Coating surfaces can impart additional functionality and modulate the mechanical properties of …

5 Different Methods Used to Fabricate Nanofibers

Nanofibers, particularly polymeric nanofibers, are a burgeoning frontier in the world of materials science, offering a diverse array of applications across industries. These fibers, typically with diameters ranging from a …