In this Tensiometry edition of our newsletter, we provide you with new application notes, webinars, and blog posts that explore contact angle misconceptions, wettability of samples with irregular shapes and sizes, optimization of battery manufacturing processes, and much more. Follow us on LinkedIn for more frequent updates on the latest news, events, and resources from Nanoscience Instruments in 2024!

APPLICATION UPDATES

NEW Application Note:

Leveraging Contact Angle Measurements to Predict Polymer Blending

Polymers are commonly blended to yield plastics with various material and mechanical properties that suit each product’s functional needs.

From consumer goods to medical devices, manufacturers are working towards creating more sustainable polymer blends, increasing the recyclability of blended polymer plastics, and identifying more stable polymer combinations for a wide range of plastic use cases.

In our new Tech Note, we explore how Contact Angle and its related methods help to predict polymer blending and provide quick and easy determination of whether polymers can form compatible mixtures. We also discuss how these methods can be applied to predict the final morphology of polymer blends to assess which compatibilizers will most improve the final blend.

Recent Blogs

Why is Camera Resolution important in Optical Tensiometry?

An optical tensiometer, also known as a contact angle goniometer, is an instrument used to characterize material surface properties and interactions between liquid and solid phases. In the simplest experiments, …

How does Surface Roughness Affect Contact Angle Measurements?

Contact angle measurements with an optical tensiometer can be quick, non-destructive, and straightforward measurements to characterize surface chemistry and understand the interaction of a surface with a liquid of interest. …

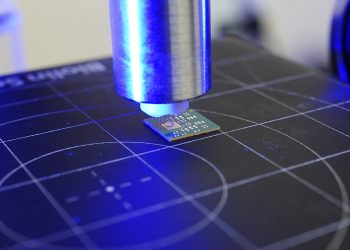

Wettability Analysis of Small Surfaces with Picoliter-Sized Droplets

The interaction between a liquid and a solid surface is a critical descriptor for a surface’s chemistry with important technological implications: it can determine how well coatings will adhere, detect …

WEBINARS

Optimizing Battery Materials with Force Tensiometry for Efficient Manufacturing

Optimizing Battery Materials with Force Tensiometer for Efficient Manufacturing

With the increased reliance on batteries for renewable energy power consumption, the development and demand for batteries will continue to rise. Outside of pure battery performance, the manufacturing process can …

Key topics covered in this webinar include:

- Material qualities that impact battery performance, and the most suitable force tensiometry methods for measuring said qualities

- Optimization and quality control of slurries for anode and cathode assembly

- Quality control of electrolytes and measurement of absorption rates for electrolyte uptake into porous electrodes and separators

App Note: Optimizing Li-Ion Battery Materials with Force Tensiometry

If you are interested in diving deeper into the data behind the webinar, we encourage you to download the accompanying Application Note, which explains in detail how to accelerate electrolyte infilling and other midstream and downstream battery manufacturing processes.

In this app note, we elaborate upon the specific force tensiometry protocols that enable you to optimize various material properties of anodes, cathodes, and separator materials in a Lithium-ion battery for more efficient manufacturing.

CONFERENCE CORNER

Meet us in San Francisco for the 245th ECS Meeting!

We look forward to showcasing our portfolio of solutions for electrochemistry, battery, and fuel cell research at next year’s ECS meeting! In the meantime, we invite you to explore our range of instruments for analyzing wettability, surface tension, and liquid uptake as they relate to electrochemical applications.