This fourth quarter Electrospinning edition is packed with new blogs, webinars, and videos. From demonstrating the formation and control of the Taylor cone to a time-lapse showing the possibility of scaling-up on the LE-500.

If you are interested in more regular updates about electrospinning news, or to be notified when our next electrospinning episode drops, we invite you to follow us on LinkedIn as well!

NEWS & UPDATES

NEW Electrospinning Video!

In Episode 3, it’s all about the Taylor cone; a fundamental concept in the world of electrospinning, whose formation and control open the door to a myriad of possibilities in scientific and industrial fields. Through a variety of examples of real-world electrospinning processes and animations that will help you zoom in on the electrostatic interactions that define the Taylor cone.

Dr. Hannah Lacy breaks down what the Taylor cone is, how it takes shape, and why it is important for producing nanofibers with your desired physical, mechanical, and chemical properties. Subscribe to our channel and hit the notification bell to stay updated on the new videos in this Electrospinning series from Nanoscience Instruments. Until next time, stay curious!

Next Episode: Electrospinning Solution Optimization: Key Solution Parameters for Success

CUSTOMER SHOWCASE

Oak Ridge National Laboratory

The U.S. Department of Energy (DOE)‘s User Facility in the Center for Nanophase Materials Science at Oak Ridge National Laboratory (ORNL) has added a new professional electrospinning system to their range of research instrumentation for studying energy, environmental, and healthcare applications—the Fluidnatek LE-50!

This robust nanofiber and nanoparticle fabrication system will enable scientists like Dr. Yue Yuan to experiment with different solvents, polymer formulations, and precursors to create new types of nanomaterials, and will be open to the wider user community in 2026.

WEBINARS

Electrospinning in Industry: Versatile and Scalable Nanomaterial Production

Electrospinning, with its ability to process a diverse range of materials and produce customizable form factors, has emerged as a versatile technique in industrial-scale materials production. Commercial electrospinning equipment stands …

CONFERENCE CORNER

MD&M 2025 | February 4-6 | Anaheim, CA

Visit us in Booth #541 to learn about the power and versatility of the electrospinning technique and discover all our solutions for medical device development and manufacturing. We will be running live demonstrations of our advanced electrospinning equipment and offering test drives of the best-selling desktop SEM to visualize the microstructure of the nanofiber samples. Our team of experts look forward to discussing how adding this technology to your lab will help you achieve your production goals!

APPLICATION UPDATES

Fluidnatek LE-500 : PCL Scale-Up Timelapse

In this video we show a 2.5 hour timelapse of PCL fibers using the LE-500. Using a 60 needle setup, it demonstrates the possibility of scaling-up with no defects!

Advancing Wound Care with Electrospinning

Wound care solutions are essential in medicine to protect injuries from infection, manage exudate, and create an optimal healing environment. Effective solutions promote faster and more efficient healing, reducing the …

From Fibers to Pharmaceuticals: Electrospinning in Drug Delivery Systems

Traditional drug delivery methods are often constrained by problems such as limited solubility and uncontrolled release. There is a growing need for innovative drug delivery methods to address these limitations. …

Electrospinning in Tissue Engineering and Regenerative Medicine

An aging population, injuries, and the prevalence of chronic diseases is leading to a growing demand for advanced therapies that can restore function and improve the quality of life. Traditional …

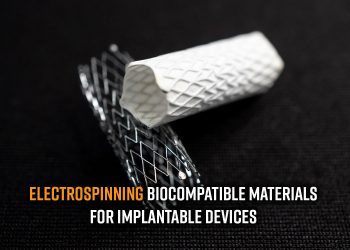

Electrospinning Biocompatible Materials for Implantable Devices

The need for implantable devices and biocompatible materials is driven by the demand for advanced medical solutions that can repair, replace, or support damaged tissues while minimizing the risk of …

SERVICE & SUPPORT

Are you interested in partnering with our Analytical Laboratory for an electrospinning project?

If you would like to explore the possibility of using electrospinning to produce nanofibrous materials for your application without the up-front investment into fabrication equipment, we invite you to start a conversation with our Electrospinning Process Development team!

We can send you an electrospun sample made from one of the many common polymers we keep in stock, or we can discuss a proof-of-concept project using the material(s) of your choice.

For more details, please reach out to our Electrospinning & Electrospraying specialists using the link below.