Fluidnatek Knowledge base

– Webinar –

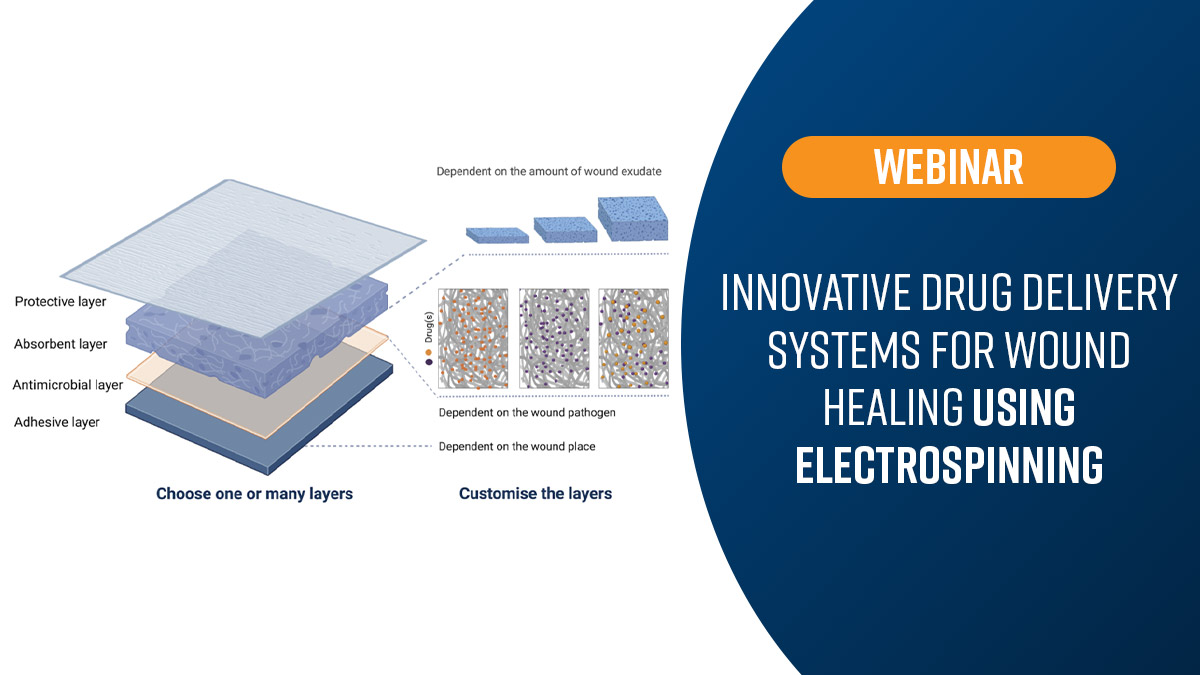

Innovative Drug Delivery Systems for Wound Healing Using Electrospinning

Chronic wounds and wound infections are a major problem…

– Tech Note –

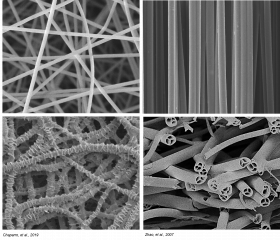

Controlling the Orientation of Electrospun Nanofibers for Tissue Engineering

Electrospinning is a versatile and promising technique for fabricating…

– App Note –

Tissue scaffolds: Perfect nanofibers with Electrospinning

What if you could quickly and easily customize the…

Product Brochure

Product Overview

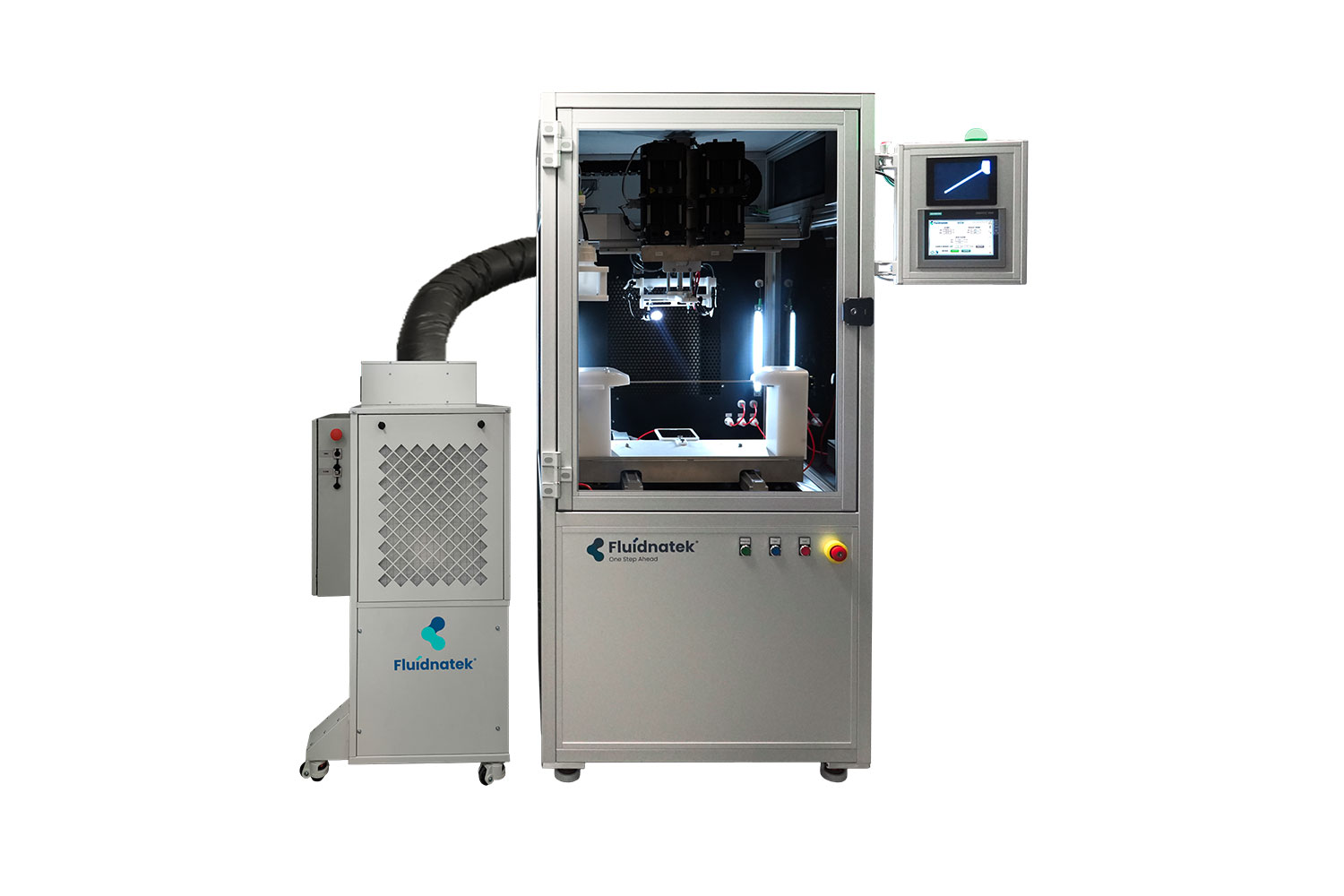

Uniquely Designed for Electrospinning Tubular BioTextiles and Medical Product

The Fluidnatek LE-100 BioTubing is the equipment of choice for GMP production of high-value samples and the ideal electrospinning system for biomedical companies that need to coat stents, or fabricate vascular grafts, heart valves, and other tubular structures in an environment that meets standards for an ISO-7 environment, cGMP, or ISO-13485 certification. The unit comes with an environmental control unit to tightly control temperature (18-45°C), relative humidity (10-80%), air flow (90-180 m3/h), and air filtration via a HEPA filter for clean processing.

Designed for Tubular Samples

Ideal for the coating of thin-diameter mandrels (D<5mm) for vascular grafts and coating of stents

Dual-end Rotating Platform

Eliminate torsional forces on thin mandrels and balances rotation from both ends of the mandrel

Full Environmental Control

Unique HEPA-filtered unit provides control over increasing or decreasing temperature (18-45°C), relative humidity (10-80%), and air flow (90-180 m³/h)

cGMP Certifiable

Leading electrospinning & electrospraying technology for pharma and biomedical processes. Validation for cGMP processes through IQ/OQ/PQ documentation packages

LE-100 BioTubing Features

The Fluidnatek LE-100 BioTubing electrospinning system was carefully designed to maintain sterile processing conditions for tubular medical device manufacturing. This unique system utilizes HEPA filtration to meet ISO-7/Class 10,000 cleanliness standards, and is constructed from materials that support easy sterilization. The LE-100 BioTubing also offers a longer sample development than the standard LE-100 model, and features a quick-release, tensioned rotating collector platform for thin diameter mandrels (1-5 mm) to efficiently exchange collectors and minimize user handling time. A rear pin electrode further improves the electrostatic field, enhancing sample deposition and uniformity. An environmental control unit (ECU) ensures precise control over the temperature (18-45°C), relative humidity (10-80%), and air flow (90-180 m3/h) during processing for perfect nanofibers, every time.

- Touchscreen controls

- Bipolarity for needle and collector (-30 to +30kV)

- Traverse rear pin electrode (-30 to +30kV)

- Dummy collector (-30 to +30kV)

- Twin-channel syringe pump

- Active exhaust system

- Rotating collector platform

- X-Y-Z-axis completely automated

- Data logging and export function

- Advanced recipe option

- Environmental control unit (ECU)

- Taylor cone visualization system

Talk to an Instrumentation Specialist Today!

Fluidnatek LE-100 BioTubing

Optional Upgradeable Features

- High definition process data hub

- Flat plate collector

- Second twin-channel syringe pump

- Solvent-gas-jacket system

- Slit injector (needle-less)

- IQ/OQ Documentation

- Audit trail & Batch control functions

- Smart Server (Remote access)

Videos & Demos

LE-100 Biotubing Videos & demos

See Available Configurations

LE-100 Biotubing Accessories

Fluidnatek equipment is extremely modular, enabling you to choose your configuration or upgrade at any time with the wide range of accessories and tools, including:

Environmental Control Unit (ECU)

- Temperature from 20ºC to 45ºC

- Relative humidity from 10% to 80%

- Air flow from 90-180 m3/h

- HEPA filtration

- Actively regulated exhaust system

Collectors

- Flat Plate

- Rotating Drum

- Rotating Mandrel

High Voltage Options

- Needle voltage

- Collector voltage

- Bipolar voltages

- Secondary spinning stage

Emitters

- Single-phase

- Coaxial (core-shell)

- Multi-needle— single phase (with and without field deflectors)

- Multi-needle— coaxial

- Tubeless dispensing system

- Slit Injector (needle-less electrospinning)

Solution Feeding Systems

- Syringe pumps (single, dual, triple)

- Syringe heater

Needle Translation

- Full scanning emitter stand

Improving Sample Consistency

- Taylor cone camera

- Solvent gas jacket

- Gas-assisted electrospinning

- Actively regulated exhaust system

Software

- Data login

- Multi-user level access

- Recipes (standard and advanced)

- High-definition process data hub

- Audit trail

- Batch control

- Smart Server (Remote Access)