Fluidnatek Knowledge base

– Webinar –

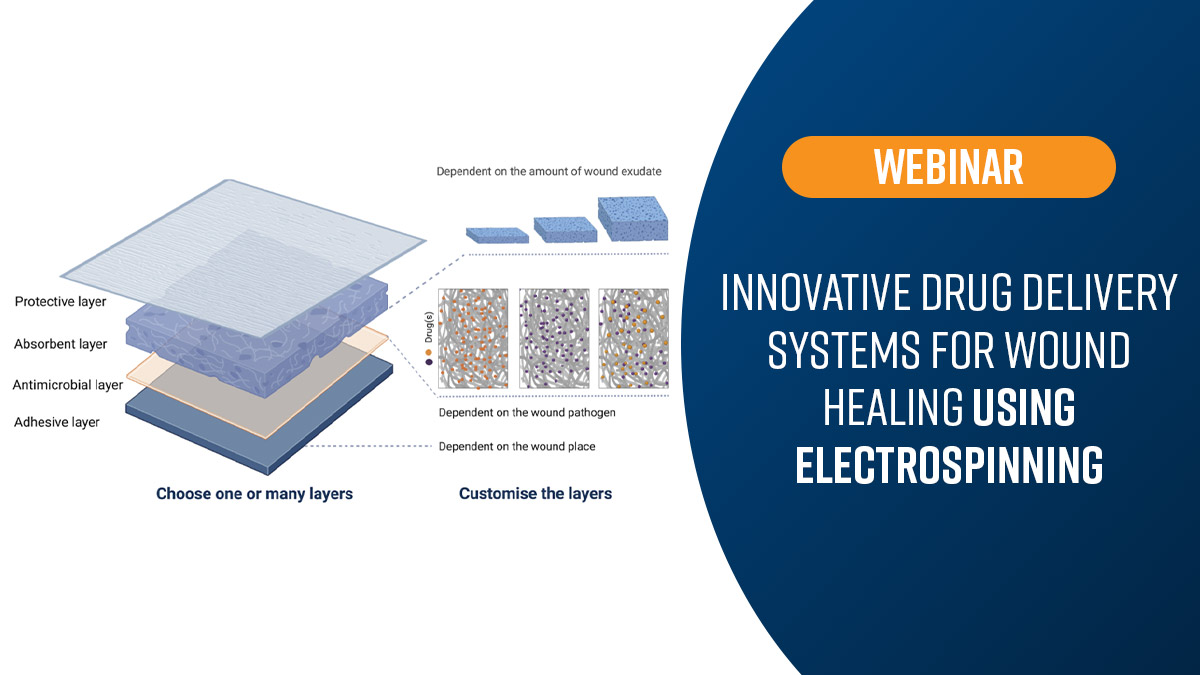

Innovative Drug Delivery Systems for Wound Healing Using Electrospinning

Chronic wounds and wound infections are a major problem…

– Webinar –

Electrospinning in Industry: Versatile and Scalable Nanomaterial Production

Electrospinning, with its ability to process a diverse range…

– Tech Note –

Controlling the Orientation of Electrospun Nanofibers for Tissue Engineering

Electrospinning is a versatile and promising technique for fabricating…

Product Brochure

Product Overview

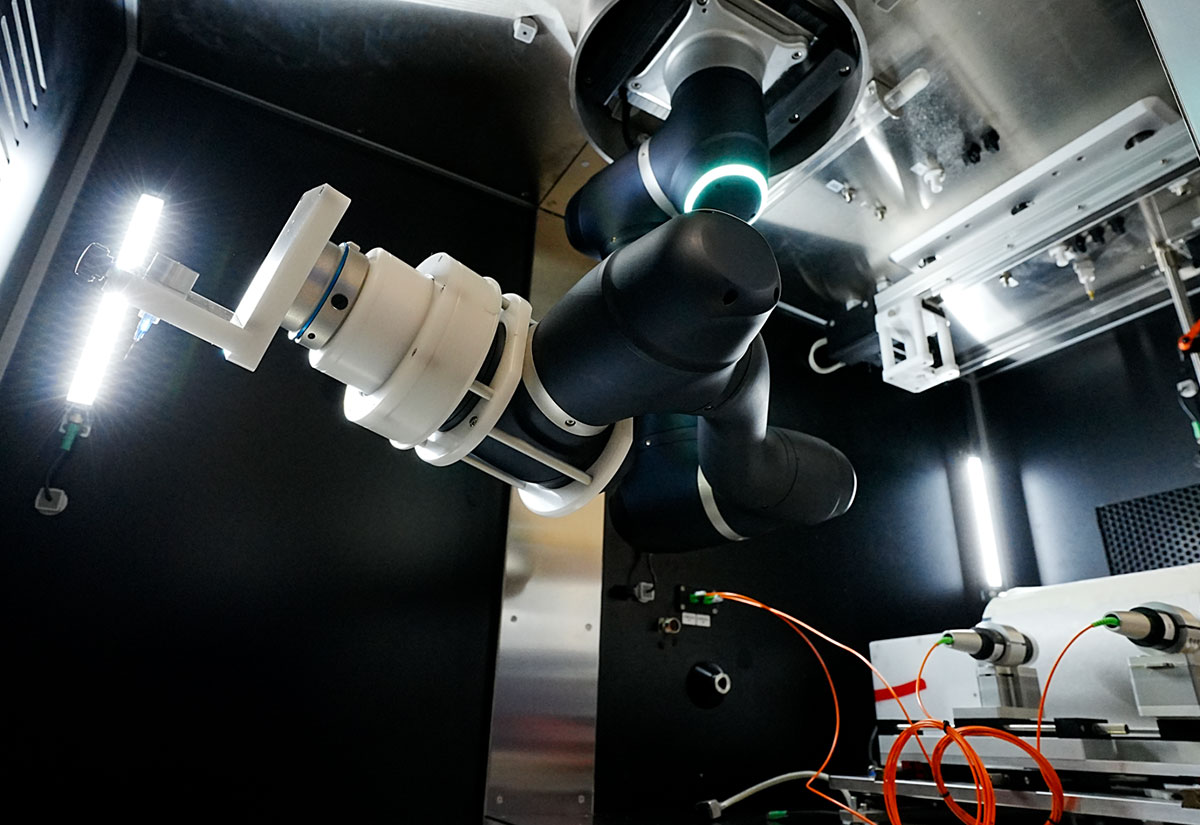

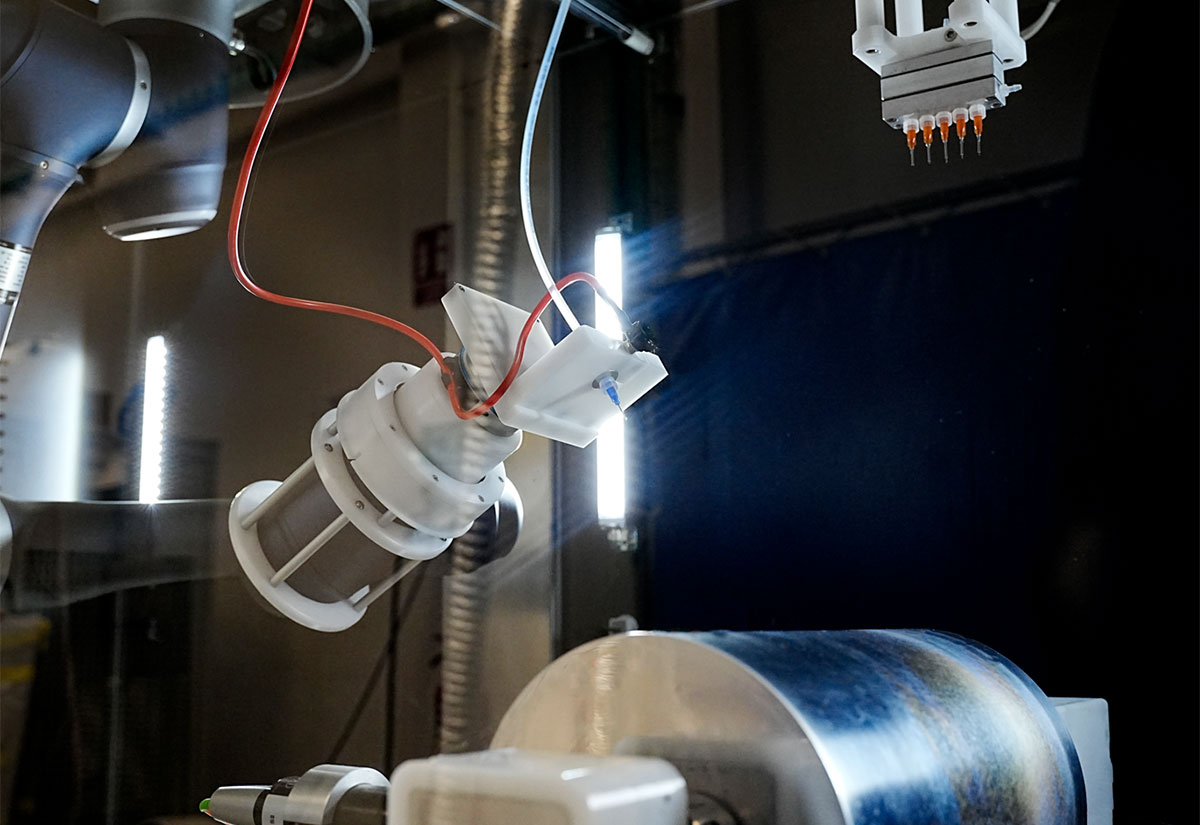

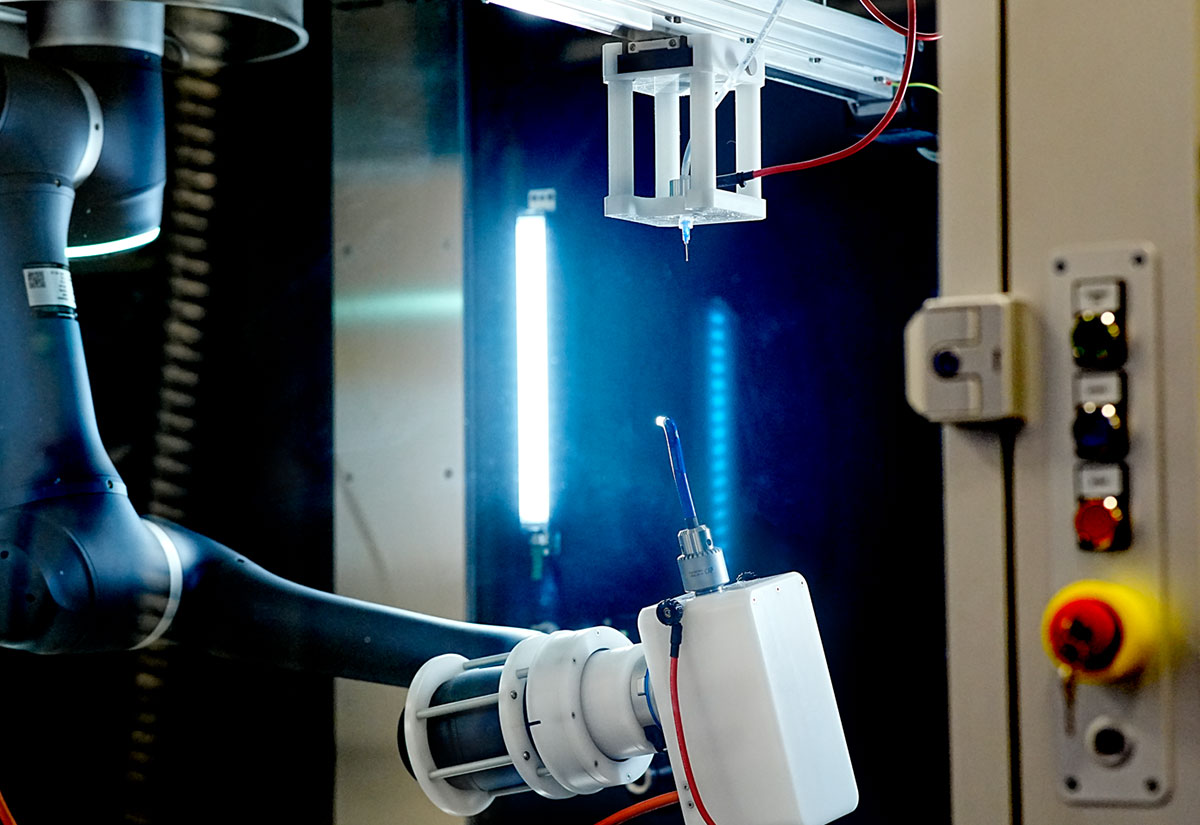

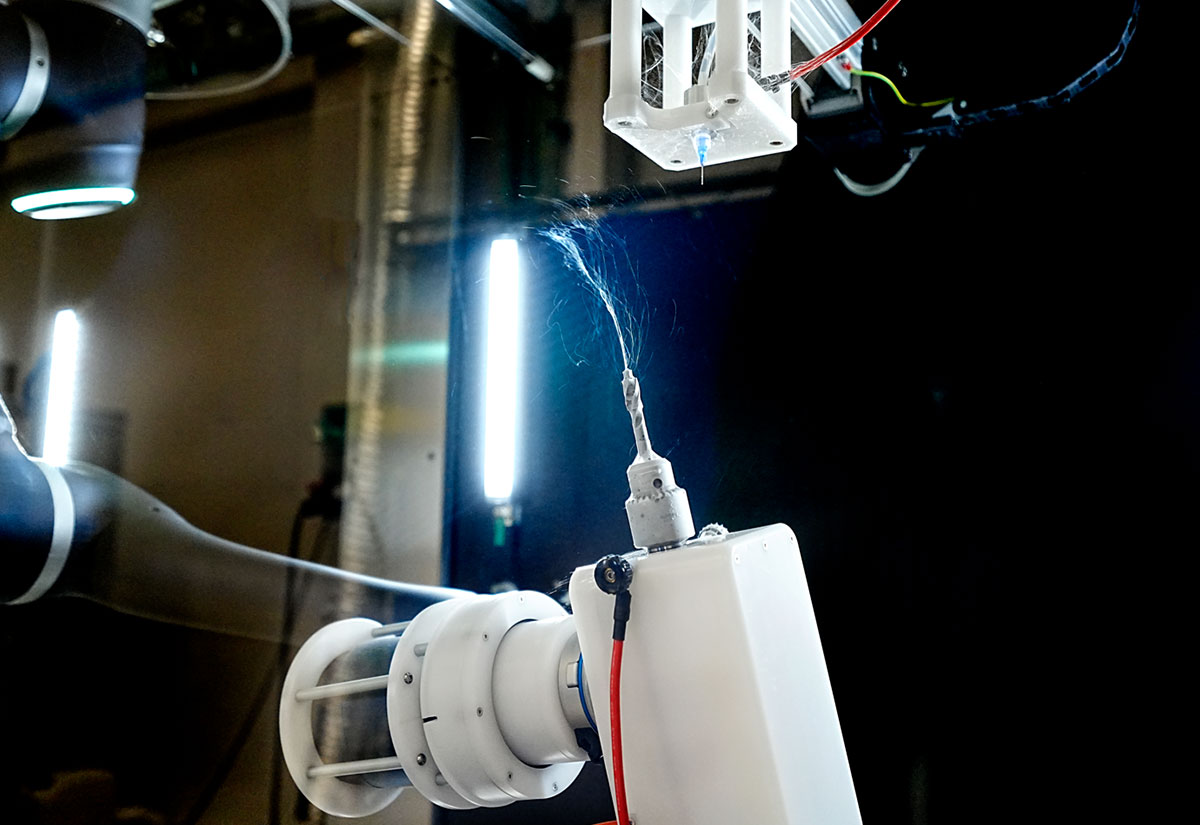

The Equipment of Choice to Efficiently Coat Complex Medical Devices and 3D Collectors

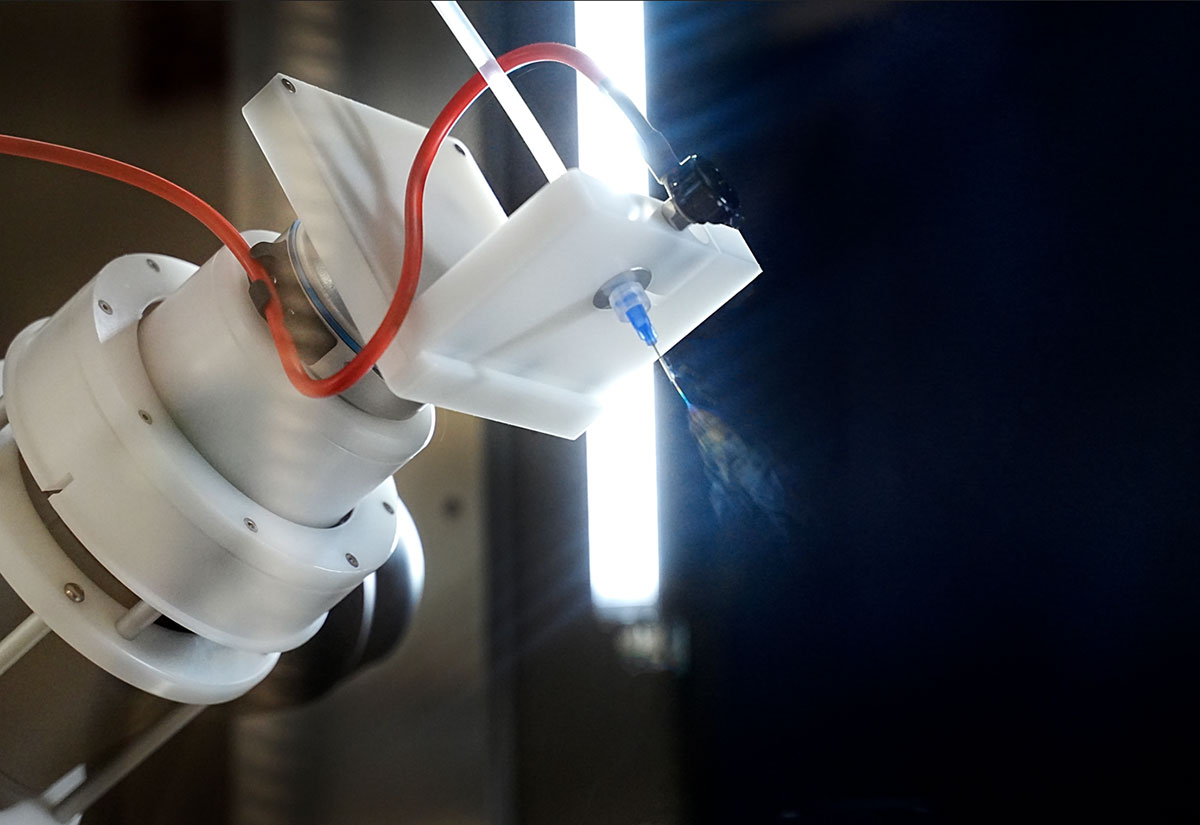

Fully engineered equipment to coat non-symmetrical and complex structures when standard commercial equipment does not suffice. The built-in robotic arm provides the flexibility needed as it can hold your medical device, or needle injector, to generate precise movements to coat it properly and efficiently with electrospun fibers.

Maximize Coating Production

Multidirectional sample processing allows coating of any 3D medical implants and medical devices with complex geometries

Full Environmental Control

Unique HEPA-filtered unit provides control over temperature (18-45°C), relative humidity (10-80%), and airflow (90-180 m3/h)

Robotic Arm for Full Flexibility

Completely programable arm able to hold rotating platform and the needle-injector for fabrication on complex structures

Production Versatility

Process up to 8 Liters of solution with up to 370 needles to generate pilot-scale quantities of electrospun or electrosprayed material

LE-500 BioDevice Features

The LE-500 BioDevice is the first electrospinning machine with integration of a collaborative robot (CoBot) arm inside its chamber. This unique feature offers an unparalleled ability to manipulate the collector or emitter in 3D space, enabling multi-step processing and variable deposition angle to coat complex medical implants, medical devices, and 3D parts. This unit also offers all capabilities of the standard LE-500 machine, including full environmental control for humidity, temperature, air flow and clean processing.

In addition, users can employ up to 370 emitters to produce electrospun fibers or electrosprayed particles, making this unit a powerful tool for product commercialization. Multiple optional upgradable features to improve production can also be implemented at any time. It employs the same core technology as Bioinicia’s full GMP production plant. This unit is capable of being ISO-13485 for medical devices and can operate at ISO-7 clean conditions.

- Pilot-scale production unit for product commercialization

- Touchscreen controls

- Primary & secondary high voltage power supply for the emitter and collector

- Robotic arm option (CoBot) built into the chamber

- Semi-continuous liquid feeding system

- Remote Ethernet access

- Automated variable target distance (emitter to collector)

- Temperature and humidity display

- Single-phase multi-emitter spinning head

- Safety shut-off switches in the access door

- Actively regulated exhaust system

Talk to an Instrumentation Specialist Today!

Fluidnatek LE-500 BioDevice

Optional Upgradeable Features

- Environmental capacity to tightly control temperature (18-45°C), relative humidity (10-80%) and airflow (90-180 m3/h)

- Robotic arm option (CoBot) built into the chamber

- Secondary stage with independent voltage to process two solutions at the same time

- Multi-needle system and/or slit injector (needle-less sample process)

- High definition process data hub to monitor 20+ process parameters

- Needle translation to improve sample homogeneity and thickness

- Rotating collector (drums, disks, mandrels)

- Roll-to-roll semi-continuous collecting system

- Large solution reservoirs to increase throughput

- Syringe heating (30-120°C)

- UV-C lamps

- Gas-assisted electrospinning head

- Inlet and outlet HEPA filters

Videos & Demos

LE-500 BioDevice Videos & demos

See Available Configurations

LE-500 BioDevice Accessories

Fluidnatek equipment is extremely modular, enabling you to choose your configuration or upgrade at any time with the wide range of accessories and tools, including:

Environmental Control Unit (ECU)

- Temperature from 18ºC to 45ºC

- Relative humidity from 10% to 80%

- HEPA filtration

- Air flow control from 90 to 180 m3/h

- Actively regulated exhaust system

- Inert atmosphere capable

Emitters

- Single-phase

- Coaxial (core-shell)

- Triaxial

- Multi-needle— single phase (with and without field deflectors)

- Multi-needle— coaxial

- Tubeless dispensing system

- Slit Injector (needle-less)

High Voltage Options

- Needle voltage

- Collector voltage

- Bipolar voltages

- Secondary spinning stage

Collectors

- Flat Plate

- Rotating Drum, Mandrel and Disk

- Roll-to-roll and Conveyor belt

- Fiber yarn collection module

Improving Sample Consistency

- Taylor cone camera

- Solvent gas jacket

- Gas-assisted electrospinning

- Actively regulated exhaust system

Needle Translation

- Y-axis automated linear emitter motion

- Z-axis automated regulation of needle distance

- Flexible articulated mounting arm

Software

- Data login

- Multi-user level access

- Recipes (standard and advanced)

- High-definition process data hub

- Audit trail

- Batch control

- Smart Server (Remote Access)

Solution Feeding Systems

- Syringe pumps (single, dual, triple)

- Twin channel syringe pumps

- High-pressure four channel syringe pumps

- Pressurized vessels

- Peristaltic pump

- Syringe heater