VSParticle Knowledge base

– Webinar –

High Throughput Synthesis of Nanoporous Thin Films

Join us for an engaging webinar as we explore…

– Webinar –

Spark Ablation as a Building Block for Nanostructured Multifunctional Devices

This webinar delves into the possibilities that spark ablation…

– Tech Note –

Clean and Tunable Model Catalyst Synthesis using Spark Ablation Technology

Heterogeneous catalysts are essential in today’s chemical industry and…

VSP-A Series Depositions Accessories provide research scientists with flexibility and speed in sample preparation. Simply attach the desired module onto the outlet of the VSP-G1 to collect nanoparticles in one of three methods: diffusion, filtration, or impaction.

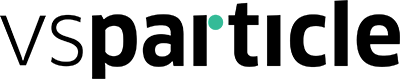

Diffusion

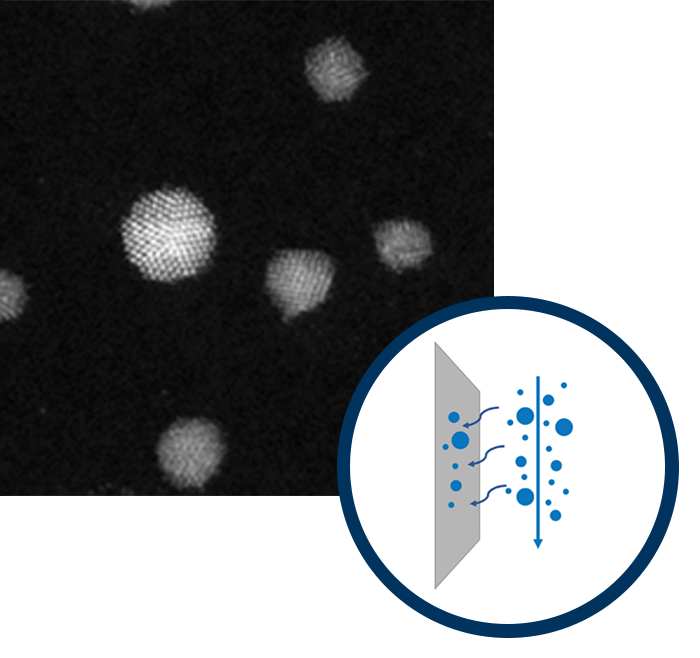

Filtration

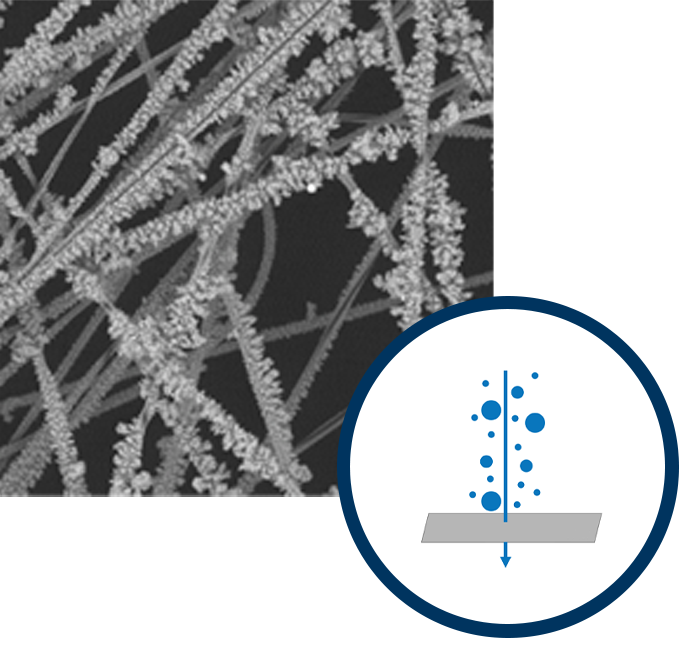

Impaction

VSP-A1 Diffusion Accessory

- Dispersed, unagglomerated particles

- Sample ready in 1-10 minutes

- Sample size 10×10 mm

- Types of substrates: TEM grids, in situ TEM chips, Electrodes, (doped) Si chips, electrodes

- Production rate: 1-10 mg/hour

VSP-A2 Filtration Accessory

- High coverage on porous substrates; bottom-up catalyst fabrication

- Mix and match oxides and metallic nanoparticles

- Collect particles with in-line filter

- Type of substrates: porous membranes, electrospun wires, carbon cloth, filter paper

- Substrate diameter = 47 mm

Applications: catalyst support decoration, filtration testing, battery anode/cathode fabrication

VSP-A3 Impaction Accessory

- Deposition of multiple layers of nanoparticles

- Grow nanoporous oxide layers

- Useful as catalyst support/sensitive material

- Types of substrates: glass, Si, TEM grids, MEMS chips

- Max deposited area: ø3 mm

Applications: battery or fuel cell anode/cathode fabrication, layered structures