Phenom SEM Automation

ParticleX Steel

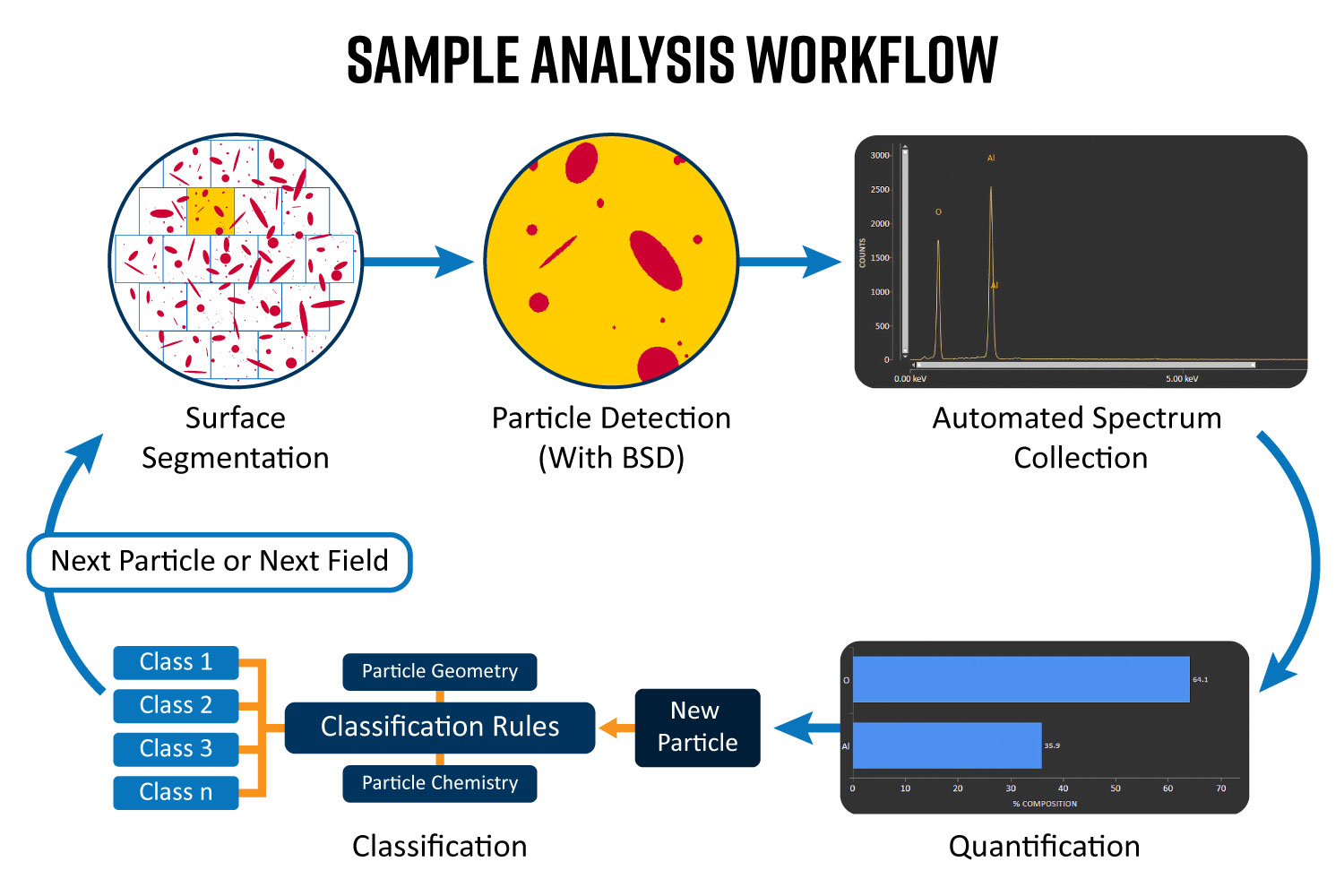

The Phenom ParticleX Steel package adds fast, automated SEM-EDS analysis to the Phenom XL Desktop SEM, enabling precise monitoring of non-metallic inclusions in steel and other metals. With pre-loaded recipes and rich data visualization tools like ternary diagrams and extreme value plots, it provides actionable insights to optimize metallurgical processes.

High-Throughput

Analyze up to 10,000 inclusions per hour with SEM-EDS without the need for a skilled operator.

Particle-Specific Data

Size, shape, composition, and position of every detected inclusion is recorded, allowing you to revisit any location for further analysis.

Standardized Reports

Maintain standards in metal cleanliness reporting with VDA 19 & ISO 16232 compliant reporting.

Talk to an Instrumentation Specialist Today!

Smart Inclusion Analysis

Metallurgists in steel manufacturing rely on inclusion analysis to evaluate the quality of their steel and optimize the production process. While some non-metallic inclusions are beneficial, others can be harmful, potentially causing production issues such as nozzle clogs or affecting the mechanical properties of the finished product. Understanding these inclusions is essential for improving steel quality and preventing production challenges.

The ParticleX Steel package for the Phenom XL Desktop SEM offers a powerful, in-house solution for automated SEM-EDS characterization of inclusions, analyzing their size, shape, and composition with precision. After the automated analysis, every inclusion can be revisited manually for further analysis. This detailed data enables metallurgists to gain valuable insights into the steel-making process, implement targeted improvements, enhance product quality, and reduce operational costs.

ParticleX Steel Example Reports

ParticleX Steel

Product Features

Turnkey Solution for Metallurgists

The ParticleX Steel package automates SEM-EDS analysis, providing a turnkey solution for metallurgists to meet ASTM standards for monitoring steel inclusions. Automating data collection and analysis significantly reduces processing time, increases productivity with continuous operation, and ensures consistent, reliable results by following predefined protocols. This approach allows for overnight operation and enables users at any experience level to conduct complex tasks without the need for extended training.

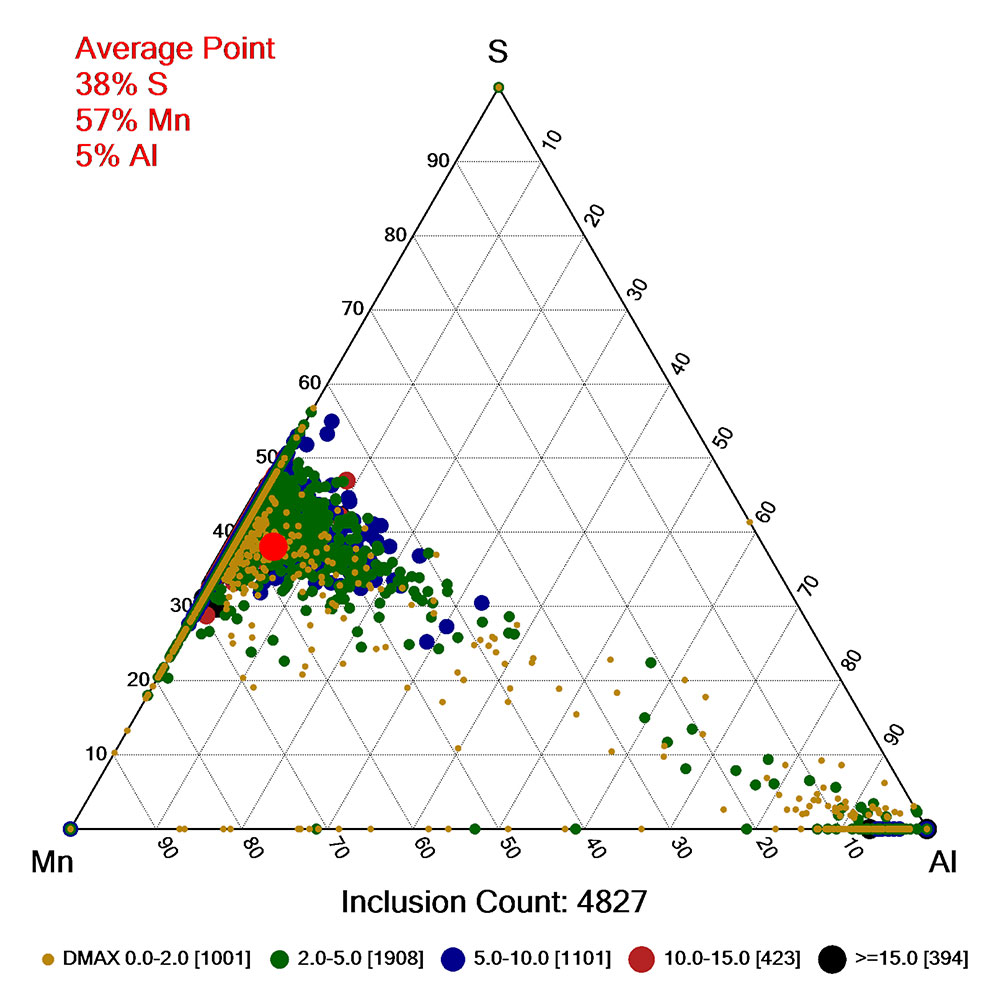

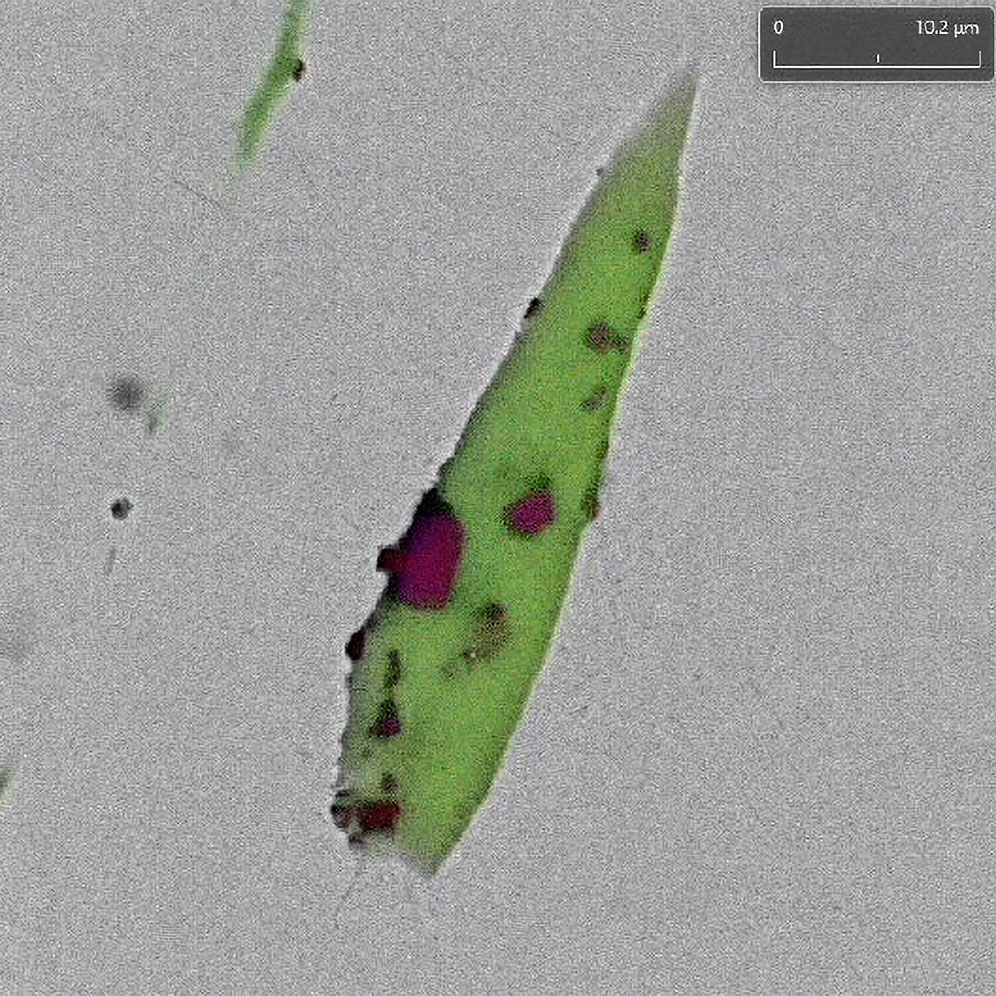

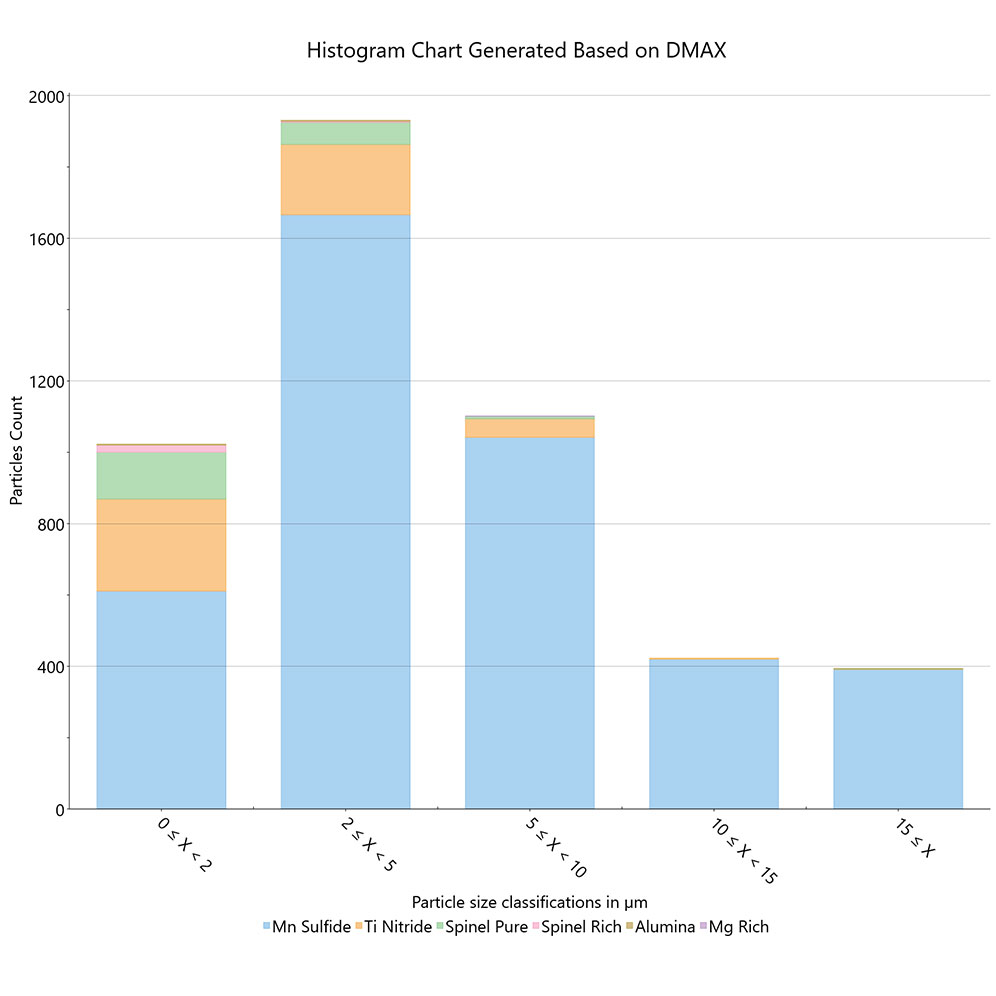

Rich Data Visualization

As important as high-throughput data collection, the right data visualization modalities allow for trends to be quickly spotted between inclusion chemistry and size. ParticleX Steel summarizes data in concise inspection reports that can contain inclusion classification summary tables, ternary plots, histogram charts, metal cleanliness ratings, and inclusion density calculations. The addition of generating extreme value plots based on ASTM E2283 allows users to easily predict the largest inclusion in a large steel volume.

Some examples of data visualization modalities available in the ParticleX Steel: ternary diagram (a), EDS map (b), and an inclusion size histogram (c).

Compliance with Industry Standards

The ParticleX Steel automation package provides a comprehensive solution for meeting three key steel inclusion monitoring standards: ASTM E45, E2142, and E2283. Unlike traditional optical microscopy, which is limited to visual classification and larger inclusions, SEM-EDS analysis with ParticleX detects inclusions at the nanoscale while providing detailed chemical composition data. Certification with ASTM E2142 enhances consumer confidence and equips producers with precise metrological data to identify areas for continuous improvement. Additionally, reports can include extreme value plots in accordance with ASTM E2283, delivering deeper insights into steel quality.

ParticleX Steel

Product Knowledgebase

Webinar

Using Automated SEM/EDS Analysis to Enhance Parts Cleanliness

Maintaining technical cleanliness is critical in industries where contamination can compro…

Blog

Benchtop STEM-in-SEM: A Powerful Tool for Tissue Ultrastructure Studies

Understanding the ultrastructure of biological tissues is essential for advancing medical…

White Paper

Phenom Pharos: A Compact Desktop STEM for Screening Negative Stained Samples

The Phenom Pharos Desktop SEM/STEM is a compact and affordable solution designed for cryo-…