PHENOM SEM AUTOMATION

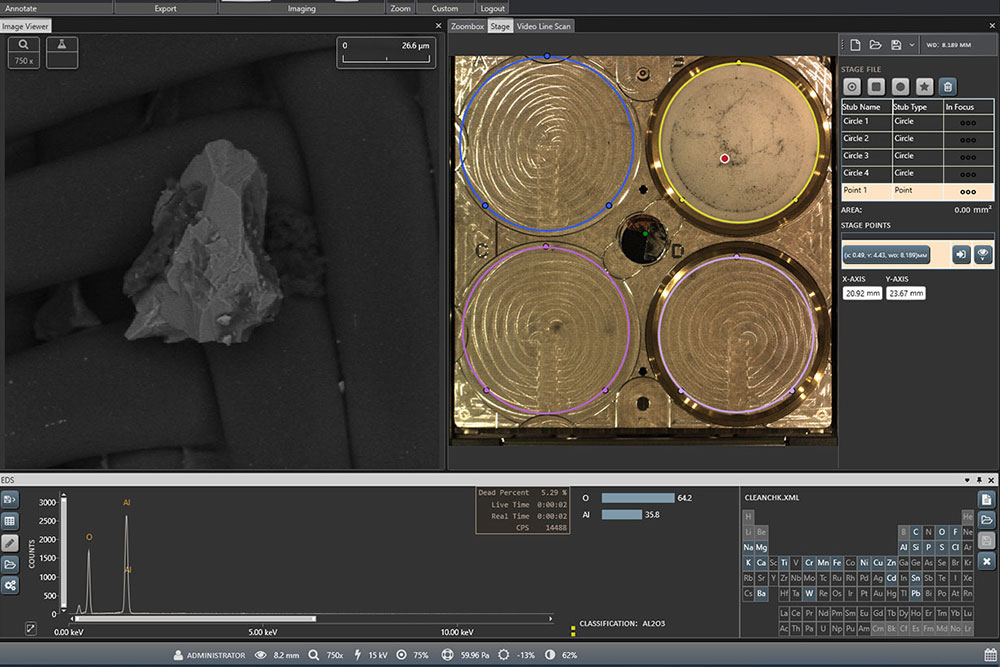

ParticleX Technical Cleanliness

The ParticleX Technical Cleanliness (TC) package for the Phenom XL Desktop SEM enables efficient in-house monitoring of particle contamination, providing detailed size, shape, and elemental composition data. With customizable pass/fail criteria and tailored reporting, it supports both industry standards and your specific quality control needs.

High-Throughput

Analyze up to 10,000 particles per hour with SEM-EDS without needing a skilled operator.

Particle-Specific Data

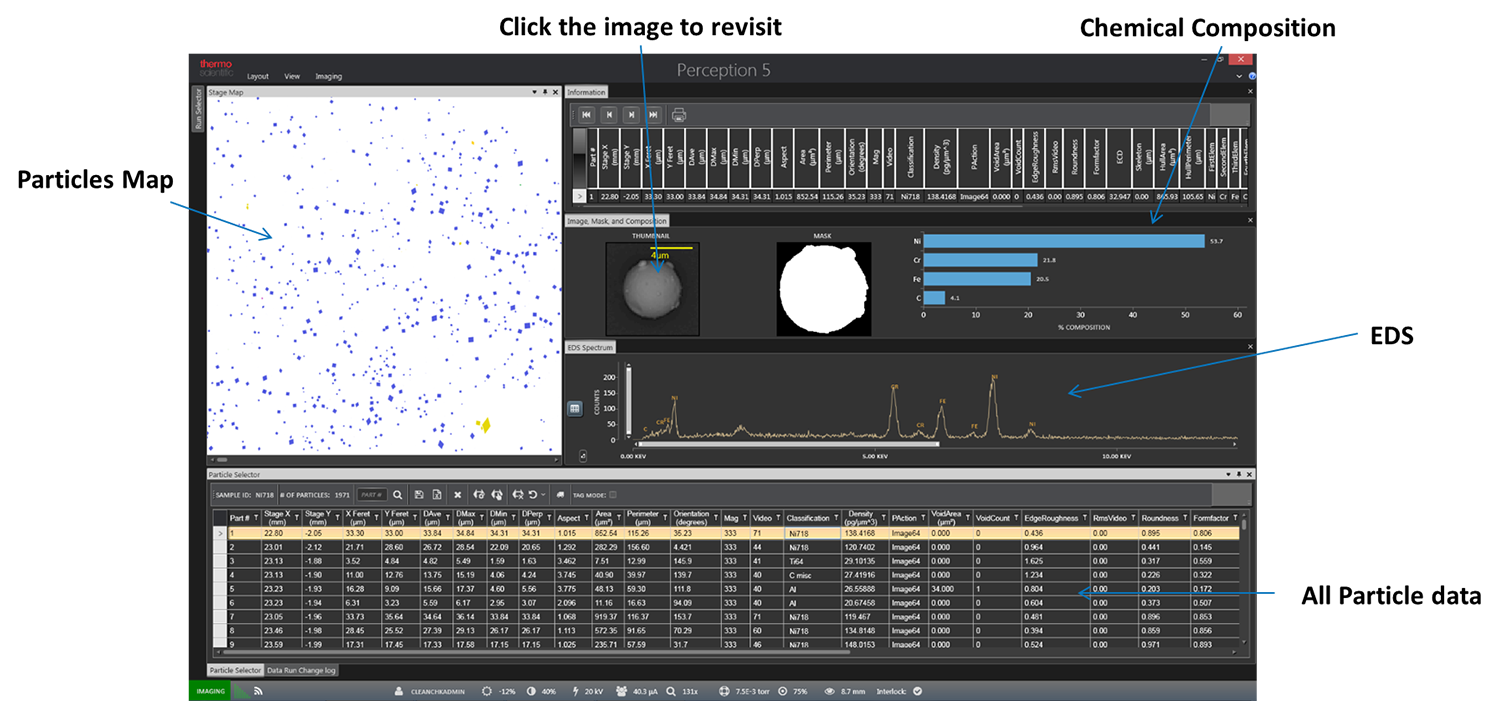

Size, shape, composition, and position of every detected particle is recorded, allowing you to revisit any location for further analysis.

Standardized Reports

Maintain safety standards with VDA 19 & ISO 16232 compliant reporting.

Talk to an Instrumentation Specialist Today!

Powerful in-house solution for Technical Cleanliness

As manufacturing specifications tighten and demand grows, comprehensive cleanliness analysis has become essential for improving workflows and reducing field failures of machined parts. Many manufacturers are shifting towards scanning electron microscopy (SEM) for monitoring contamination. The ParticleX Technical Cleanliness package provides a powerful in-house solution, enabling automated SEM-EDS characterization of particle size, shape, and chemical composition. This data empowers manufacturers to make targeted quality improvements, enhance part reliability, minimize field failures, and reduce costs.

ParticleX Technical Cleanliness

Product Features

Most effective method for TC inspections

ParticleX TC is an automated scanning electron microscopy solution that not only provides morphology information but can provide the elemental composition of each particle. Compared to first-line approaches like optical microscopy, gravimetric analysis, or particle counters, ParticleX TC provides essential particle-specific data needed to identify sources of contamination. End-to-end automation makes implementing this advanced technique straightforward as there is no need for a skilled operator to run the analysis.

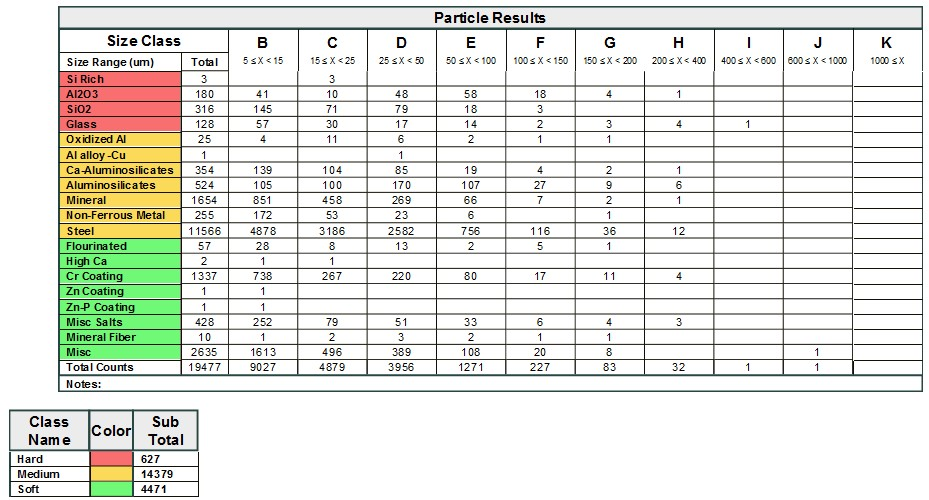

Customized and unbiased reporting

ParticleX TC summarizes data in concise reports including particle counts per size range, composition, hardness, and conductivity. Custom cleanliness rules allow maximum particle counts to be set for each classification rule based on size, hardness or other properties for actionable pass-fail reporting. With access to particle-specific composition based on EDS data, ParticleX TC is the only method capable of providing particle analysis to this level of specificity.

Ensure compliance with industry standards

With ParticleX TC, you can implement standardized contamination analysis with SEM that’s aligned to key industry standards, including VDA 19 and ISO 16232. This allows manufacturers to meet customer requirements and regulatory expectations, across the supply chain, with confidence. By adhering to these globally recognized benchmarks, ParticleX TC helps streamline audits and ensures consistency across quality control processes

ParticleX Technical Cleanliness

Product Knowledgebase

Using Automated SEM/EDS Analysis to Enhance Parts Cleanliness

Maintaining technical cleanliness is critical in industries where contamination can compro…

Automated SEM: The Future of Particle Analysis

Particle analysis involves characterizing the size, morphology, and composition of powders…

Large-scale SEM Imaging with Automated Image Mapping

Acquiring large-scale images using SEM can result in trade-offs between resolution and tim…