Talk to an Instrumentation Specialist Today!

Phenom XL Sample Stages

Eucentric Stage

In many SEM applications, a user can gain more insight into sample properties if the sample can be tilted and rotated. The 6-axis Eucentric Stage for the Phenom XL has been specifically developed with that purpose in mind. The advanced holder contains a sub-stage that allows users to easily and safely look at a sample from all sides. A sample can be lifted, tilted, rotated and shifted without losing sight of the sample detail, while integrated anti-collision algorithms keep both sample and SEM safe. In addition, this holder features a live CAD rendering of the chamber for a visualized navigation.

Key Specifications:

- True Eucentric Movement: The 6-axis stage allows for true eucentric movement of the sample, allowing an area to stay in focus while the sample tilts

- Anti Collision Mechanism:

Tilt samples up to 90˚ while taking advantage of an integrated anti-collision safety mechanism

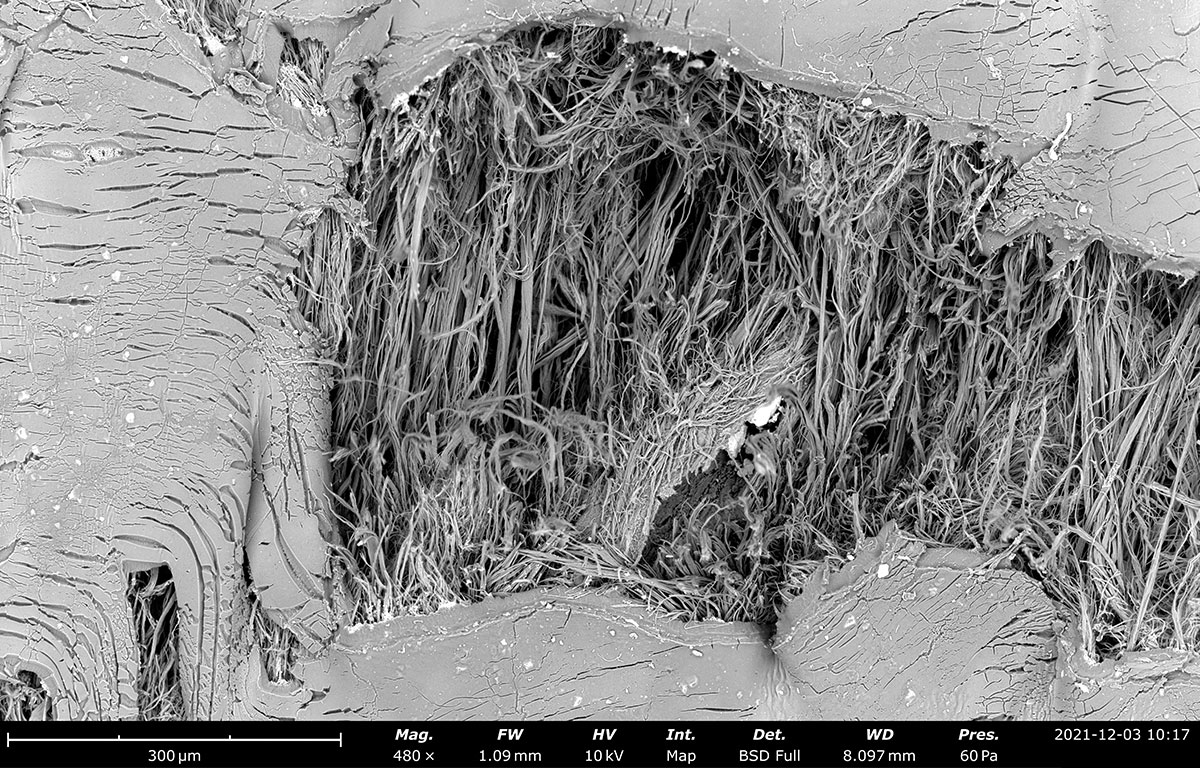

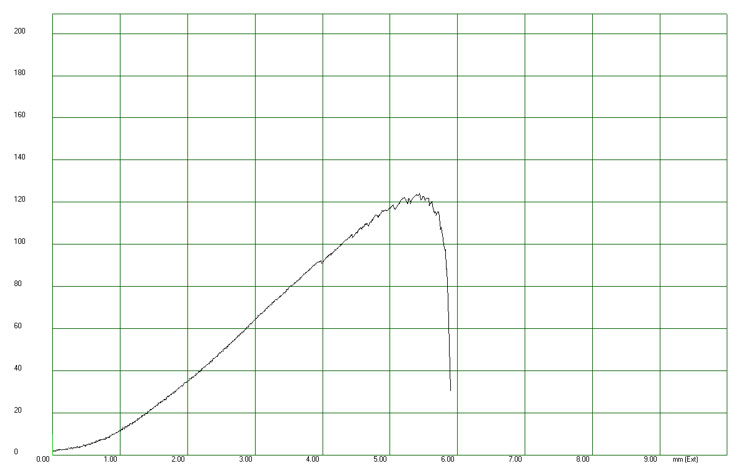

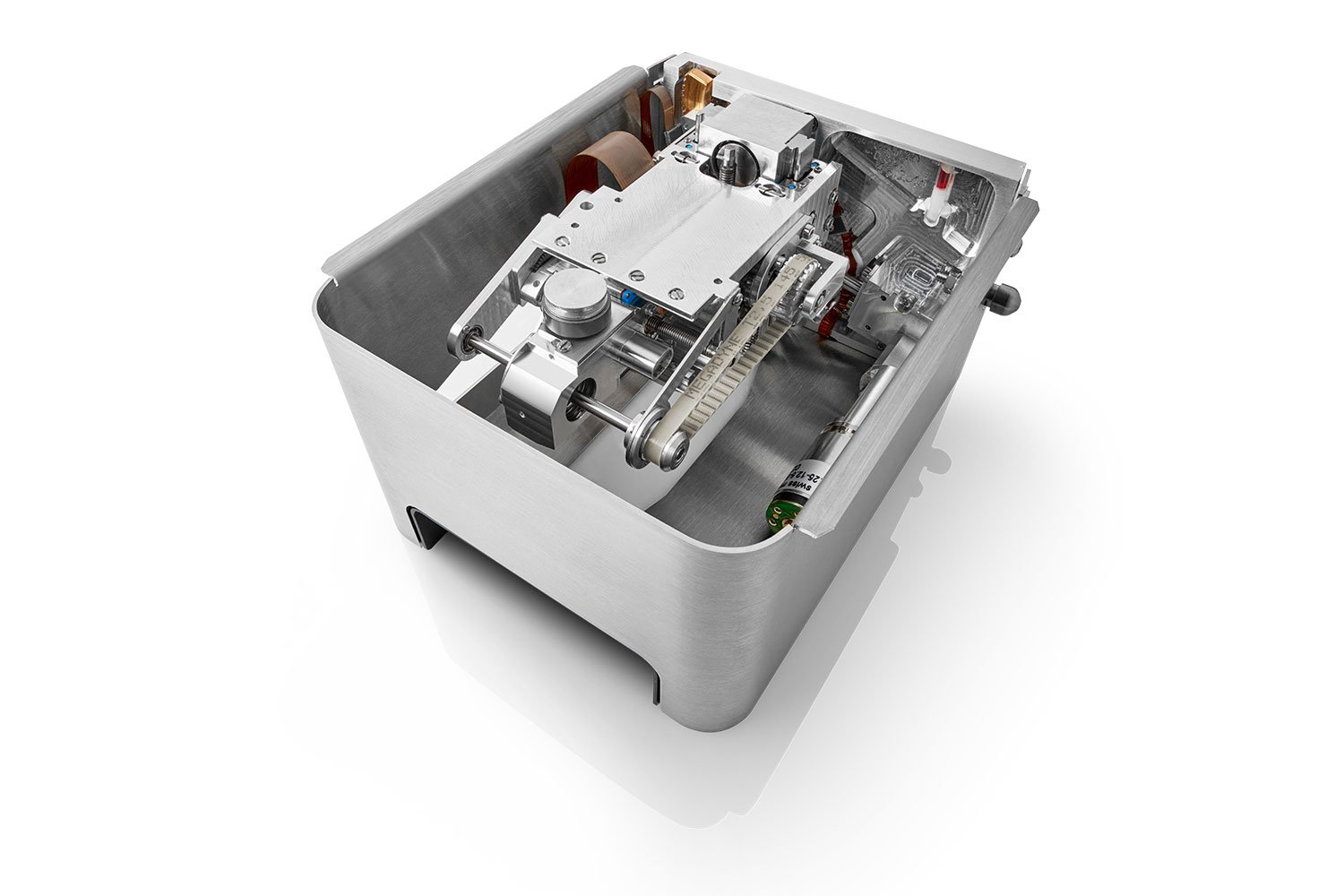

Tensile Testing Stage

Tensile testing is one of the simplest and most widely used mechanical tests for understanding material properties and predicting how products will behave in their intended applications. Once a material is pulled to breaking point, it is often analyzed in an SEM to determine the mechanism of failure. Now, these two steps can be combined using the tensile sample holder for the Phenom XL desktop SEM.

Key Specifications:

- Flexible Options: Choice of 150-N and 1000-N load cells

- In Situ Mechanical Testing: Capture SEM images during load cycles

Accessory Features:

The tensile/compression stages have been designed in collaboration with Deben for use within the Phenom XL. The modules allow many different materials to be deformed and stretched at loads of up to 100 Kg (1 kN). There are two modules and load cells available: 150 N and 1000 N; the choice depends on the type of sample and the tests being carried out.

Tensile testing is used to:

- Determine batch quality

- Determine manufacturing consistency

- Aid the design process

- Reduce material costs and achieve lean manufacturing goals

- Ensure compliance with international and industry standards

Resin Mount & Metallurgical Stage Inserts

Resin mounted and surface polished samples are useful when investigating grain structures, revealing cross-sections, or performing failure analysis. Resin Mount Stage Inserts for the Phenom XL clamp the sample near the top surface, so all samples will remain level and at the same working distance without modifying their bottom surfaces, ideal for automated imaging and/or quantitative EDS analysis.

Key Specifications:

Sub Size Flexibility: Available in three standard sizes: 25mm (1 inch), 32mm (1 ¼ inch), and 40mm (1 ½ inch) diameters

Easy Sample Loading: Quickly load samples with an easy clamping mechanism with allen key.

Consistent Imaging: Maintains all samples at the same working distance, allowing you to maintain the same imaging settings.

Filter Stage Inserts

Filter and membrane samples, which are often used for filter residue analysis, must be mounted firmly and flat into the SEM system for correct analysis. As filters and membranes are often delicate materials, mounting these samples without the use of an insert can lead to folding and damage. The use of traditional, often highly sticky, carbon tape prevents the sample from being re-used for future analysis. By using the filter inserts with the Phenom XL, mounting and replacing filter samples can be done easily.

Key Specifications:

- Keeps Samples Flat: Maintain focus throughout imaging the sample

- No Sticky Tape Needed: Reuse samples for further analysis

Product Specs:

| Sample diameter | 25 mm | 47 mm |

| Sample capacity | 9 filters or membranes | 4 filters or membranes Extra space for 3×12 mm reference sample |

| Clamping mechanism | Weighted cover plate | 4 Individual weight rings |

| Material | Aluminum | Aluminum |

| Included tooling | Torx 10 key for cover plate | 4 Messing weight rings & allen key for reference sample |

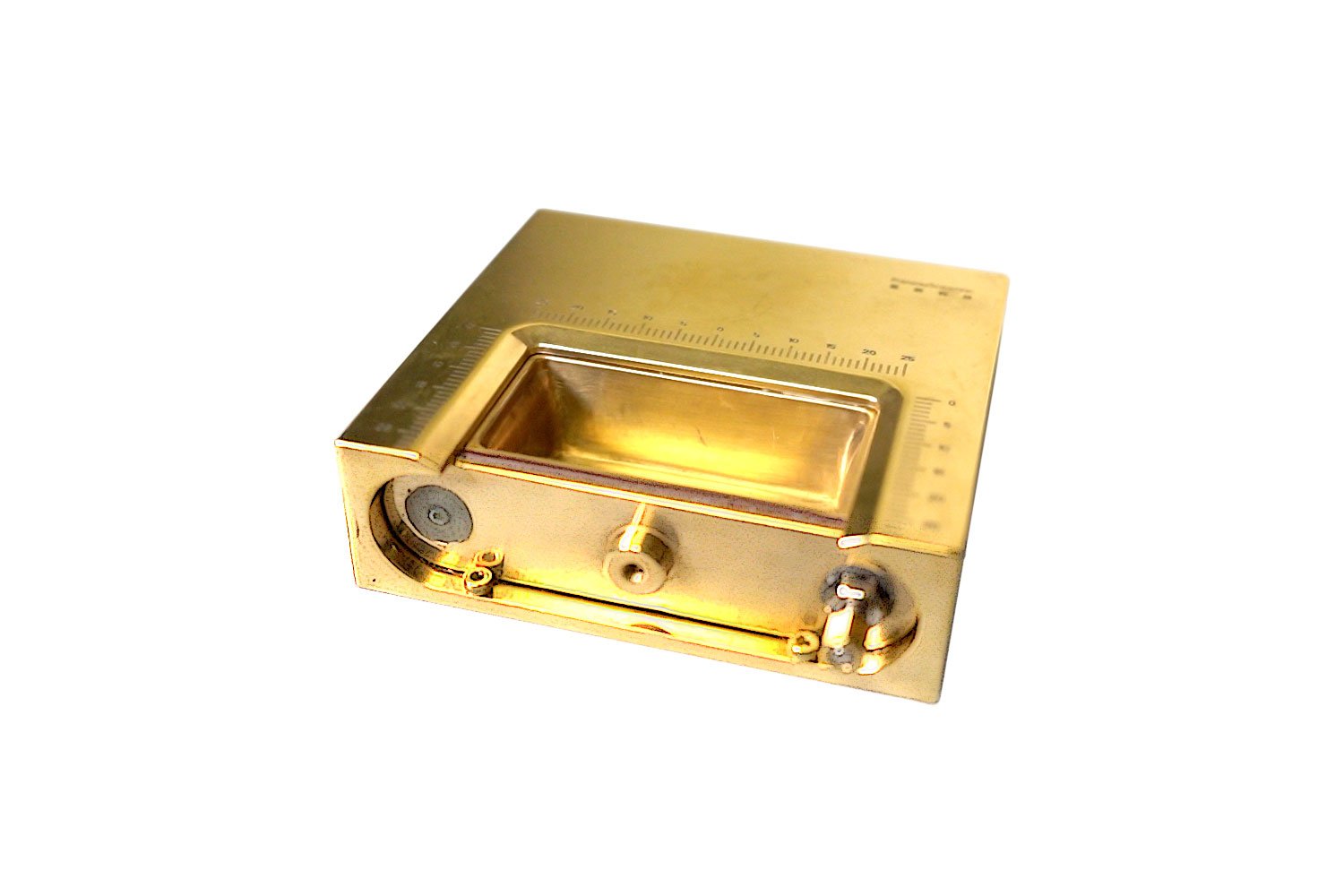

Vacuum Transfer Box

The Vacuum Transfer Box is designed to protect samples sensitive to oxygen or moisture. Samples can be prepared in a glove box and enclosed in the holder to maintain inert atmosphere during transfer to the Phenom XL. Once the holder is under vacuum in the sample chamber, the holder will automatically open to expose the samples for analysis. The Vacuum Transfer Box is an ideal solution when working with battery materials.

Key Specifications:

Automatic open/close: the vacuum sample holder will automatically open under vacuum inside the Phenom XL, and automatically close when vacuum is released

Comprehensive Functions: Charging/discharging, force measurement, cooling-heating are optional for in-situ applications

Easy Mounting: customized base is easily attached to the Phenom XL standard sample holder

Non-magnetic: Components are made of non-magnetic materials that will not affect the electron beam or lenses

Phenom Desktop SEM

Product Knowledgebase

Webinar

Practical SEM and Ion Mill Applications for Semiconductor R&D to Production

Scanning Electron Microscopes (SEMs) and Cross-sectioning/Polishing tools play a vital rol…

Blog

Broad Ion Beam vs. Focused Ion Beam Polishing: Choosing the Right Technique for Sample Preparation

When preparing samples for electron microscopy, the choice of method directly impacts the…

White Paper

Understanding Nickel Manganese Cobalt (NMC) Precursor Cathode Active Material (pCAM)

As the battery industry strives for more efficient and environmentally friendly solutions…