Polymer compounding & shaping equipment

Micro compounding systems & Shaping instruments

Xplore’s high-quality, reliable micro compounding and shaping instruments offer cost-effective solutions for R&D, accelerating time-to-market. The benchtop micro compounders replicate the performance of large twin-screw compounders while providing precise control over temperature, mixing intensity, and processing time. With sample volumes ranging from 2 ml to 40 ml, researchers can quickly produce test samples, minimizing material consumption and reducing R&D costs. Designed for use in fume hoods, these systems enhance operator safety by limiting exposure to hazardous substances.

Reliable and Reproducible

Separate heating zones offer perfect control of temperature resulting in reproducible processes.

High Quality

A fluid-tight, abrasion and chemical resistant barrel works flawlessly for many years.

Cost Efficient

Use of small sample volumes, fast processing time and easy cleaning contribute to a cost-efficient system.

Micro compounders

Available configurations

Xplore’s micro compounders provide high-quality, reliable, and reproducible results with precise rheological data. Equipped with three separate heating zones for optimal temperature control and a durable, fluid-tight barrel, these systems ensure long-term consistency. The efficient mixing process reduces processing time, while the easy-to-clean design minimizes batch turnaround. With sample volumes ranging from 2 ml to 40 ml, researchers can perform early-stage testing and lower screening costs. Quick sample and screw exchanges offer flexibility for experimentation, with adjustable recirculation, process time, and mixing parameters.

The MC 40, a 40 mL compounder, offers enhanced performance, exceptional efficiency, and consistent stability.

The MC 15 HT, a 15 ml compounder, is engineered to streamline and accelerate R&D.

The 5 mL Micro Compounder enables testing of new formulations and materials while minimizing the use of costly compounds and additives.

Polymer shaping tools

Available Systems

Xplore’s shaping instruments—such as injection molders, fiber lines, cast film lines, and a 3D filament line—integrate seamlessly with both Xplore and third-party extruders, ensuring efficient material processing. These advanced solutions facilitate precise, scalable material development, driving innovation and improving R&D efficiency.

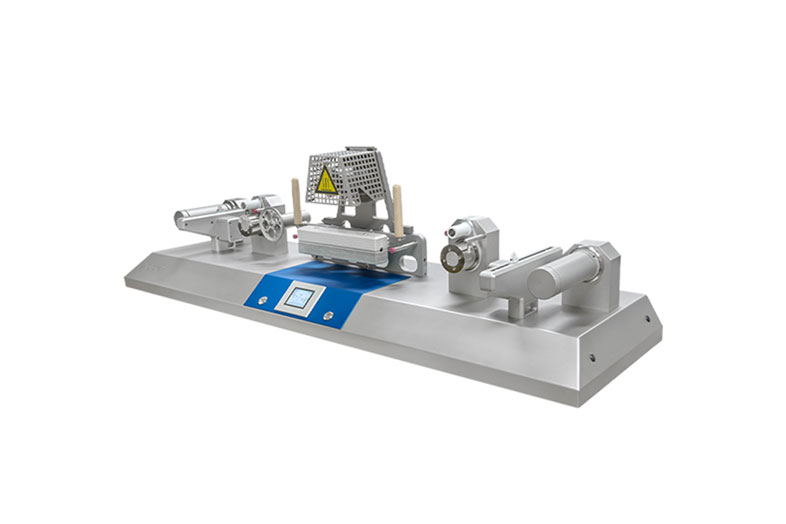

The IM 12 Micro Injection Molder is a compact, high-precision solution that seamlessly integrates with Xplore micro compounders or operates as a standalone unit.

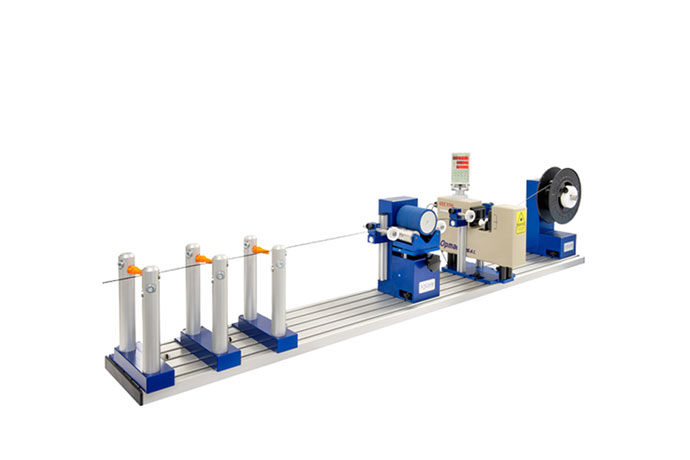

Xplore Microfiber Line enables the rapid and efficient production of long fiber samples without requiring an additional spinning pump. This significantly reduces material waste, development time, and R&D costs.

Xplore’s 3D filament line is engineered to produce high-quality Fused Deposition Modeling (FDM) filaments with exceptional dimensional stability while minimizing material usage.

Micro Cast Film Lines are designed to produce high-quality cast films using only a few grams of material and are fully compatible with Xplore micro compounders.

The CB Pro unit is designed to guide polymer strands directly from a small extruder or compounder, seamlessly integrating with Xplore micro compounders for efficient processing.

The Xplore Pro Pelletizer, compatible with all Xplore micro compounders, is an R&D-sized granulation unit designed to cut polymer and rubber strands into a diverse range of pellets.

Applications

Micro compounding Applications

Micro compounding has a wide range of applications in a range of disciplines.

- Polymers

- Polymer composites

- Rubbers and Elastomers

- Sustainability

- Biomedical

- Nutrition