Phenom Desktop SEM

ProSuite Image Analysis Software

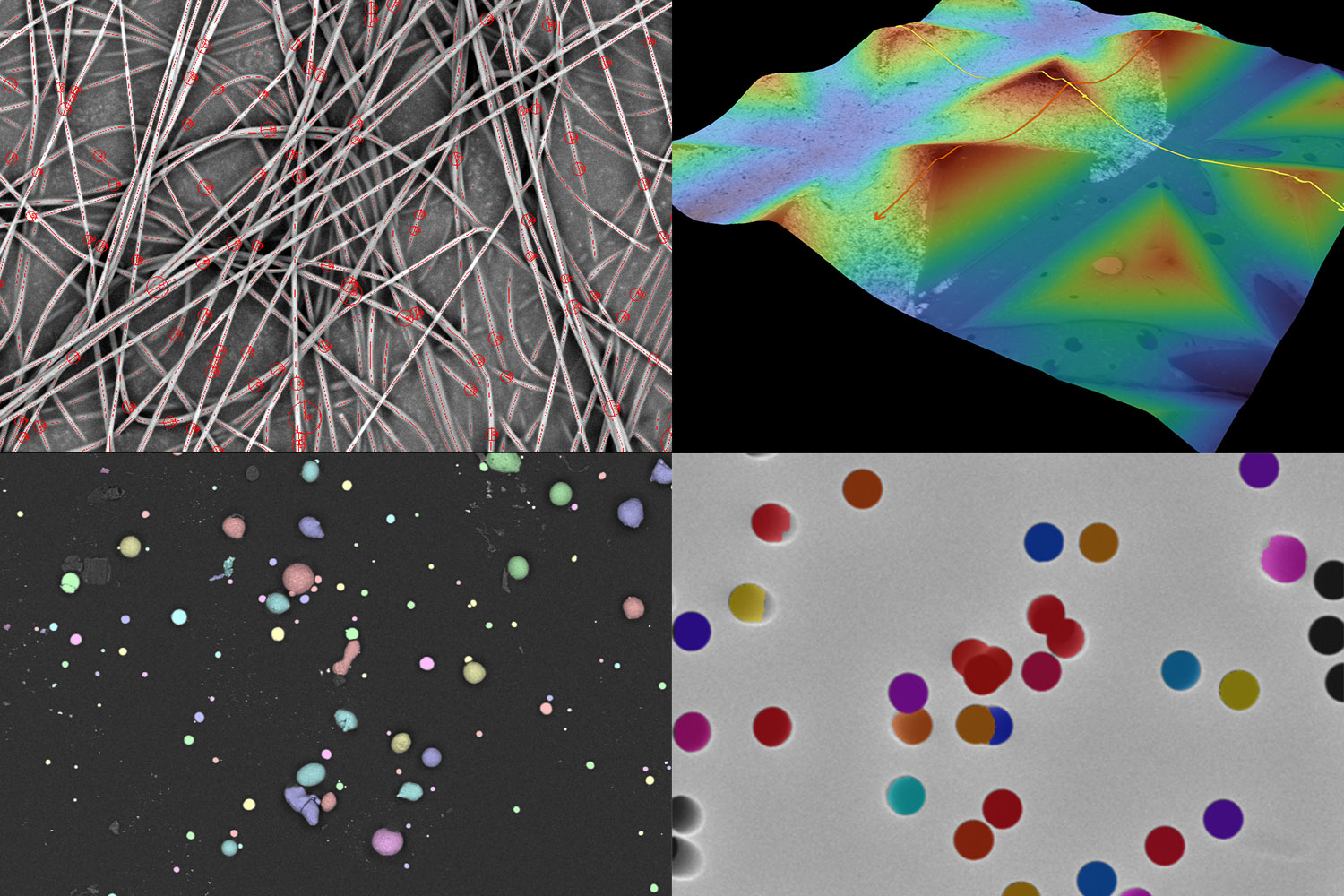

The ProSuite image analysis software is developed specifically for the Phenom SEM to deliver automated high throughput quantitative analysis of surface features while eliminating user bias. It includes ParticleMetric (particle size & shape analysis), PoroMetric (pore size and shape analysis), FiberMetric (fiber diameter and orientation analysis) and 3D Roughness Reconstruction (to generate three- dimensional images).

Particle size distribution and shape analysis

Pore size distribution and shape analysis

Fiber diameter and orientation analysis

Surface topography and roughness measurement

Talk to an Instrumentation Specialist Today!

Phenom ProSuite Image Analysis Software

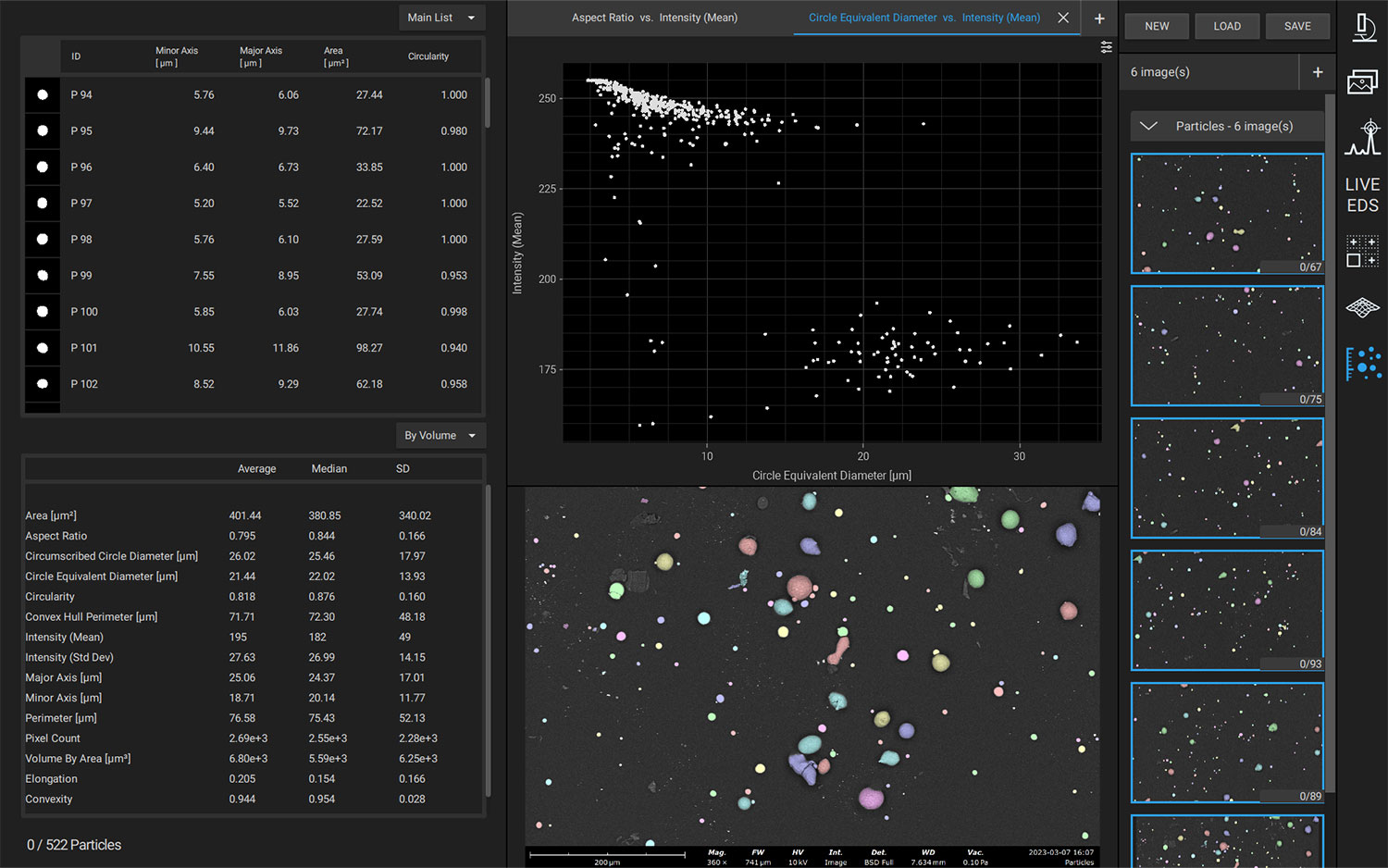

ParticleMetric

ParticleMetric automates particle detection, analysis, and reporting to provide statistically significant particle size and shape data for submicron particles. The software includes data visualization tools including histograms and scatter plots so that trends can be quickly identified. ParticleMetric provides a level of visual interpretation and quantification beyond the limits of optical microscopy that can enhance quality control and accelerate process development.

Key Specifications

- Correlate particle features such as diameter, circularity, aspect ratio, and convexity

- Analyze up to 1000 particles per minute

- Combine with Automated Image Mapping for statistical data analysis with high-quality SEM images

- Revisit detected particles for further analysis

- Visualize large datasets in histograms or scatter plots of any given parameter

- Plot graphs in linear, log, or double log scale – by number or volume

- Identifies and confirms phenomena such as broken particles, agglomerates, and foreign particles

- Reporting tool allows easy exporting of data

Phenom ProSuite Image Analysis Software

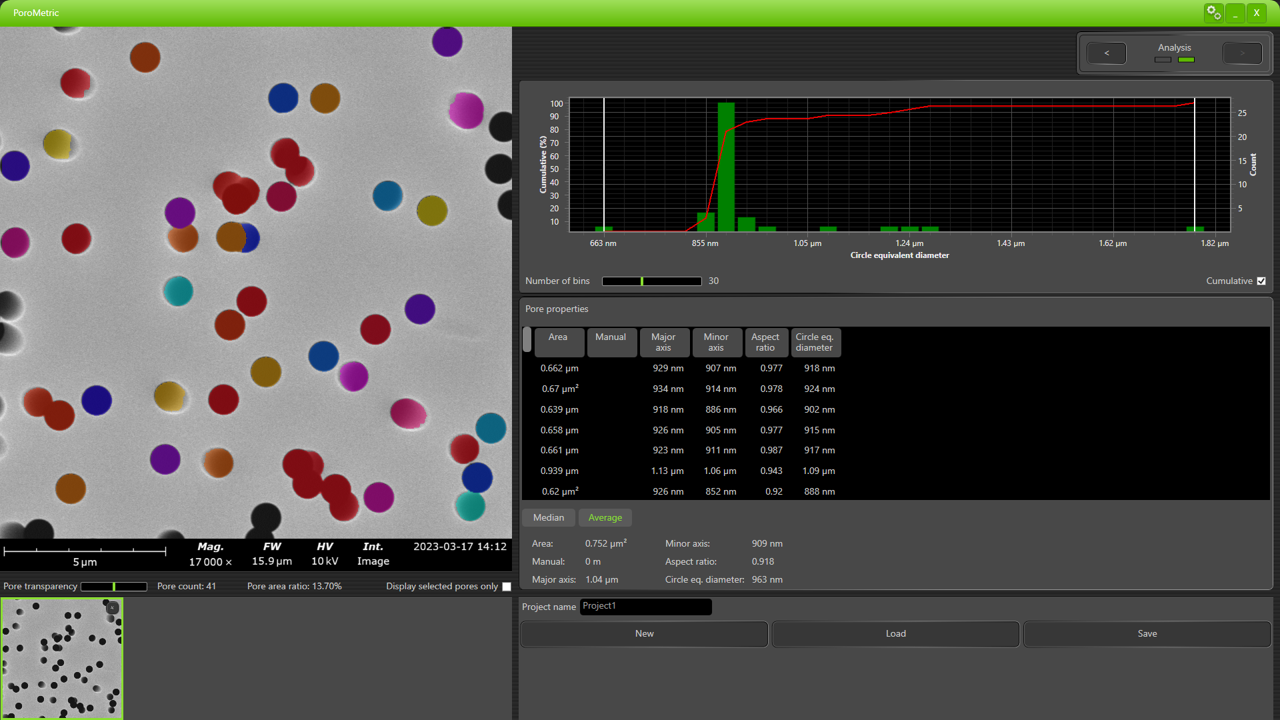

PoroMetric

PoroMetric automates pore detection, analysis, and reporting. The PoroMetric software allows users to generate measurements regarding a sample’s porosity, including percent porosity of the sample. Large datasets including pore size and aspect ratio distributions can be easily generated. PoroMetric is the best in its class for accurate and high-throughput analysis of porous materials

- Correlate pore features such as area, aspect ratio, and circle equivalent diameter

- Detection speed up to 1000 pores/minute

- Combine with Automated Image Mapping for statistical data analysis with high-quality SEM images

- Manual measurement capability

- Annotated SEM images of detected pores

Phenom ProSuite Image Analysis Software

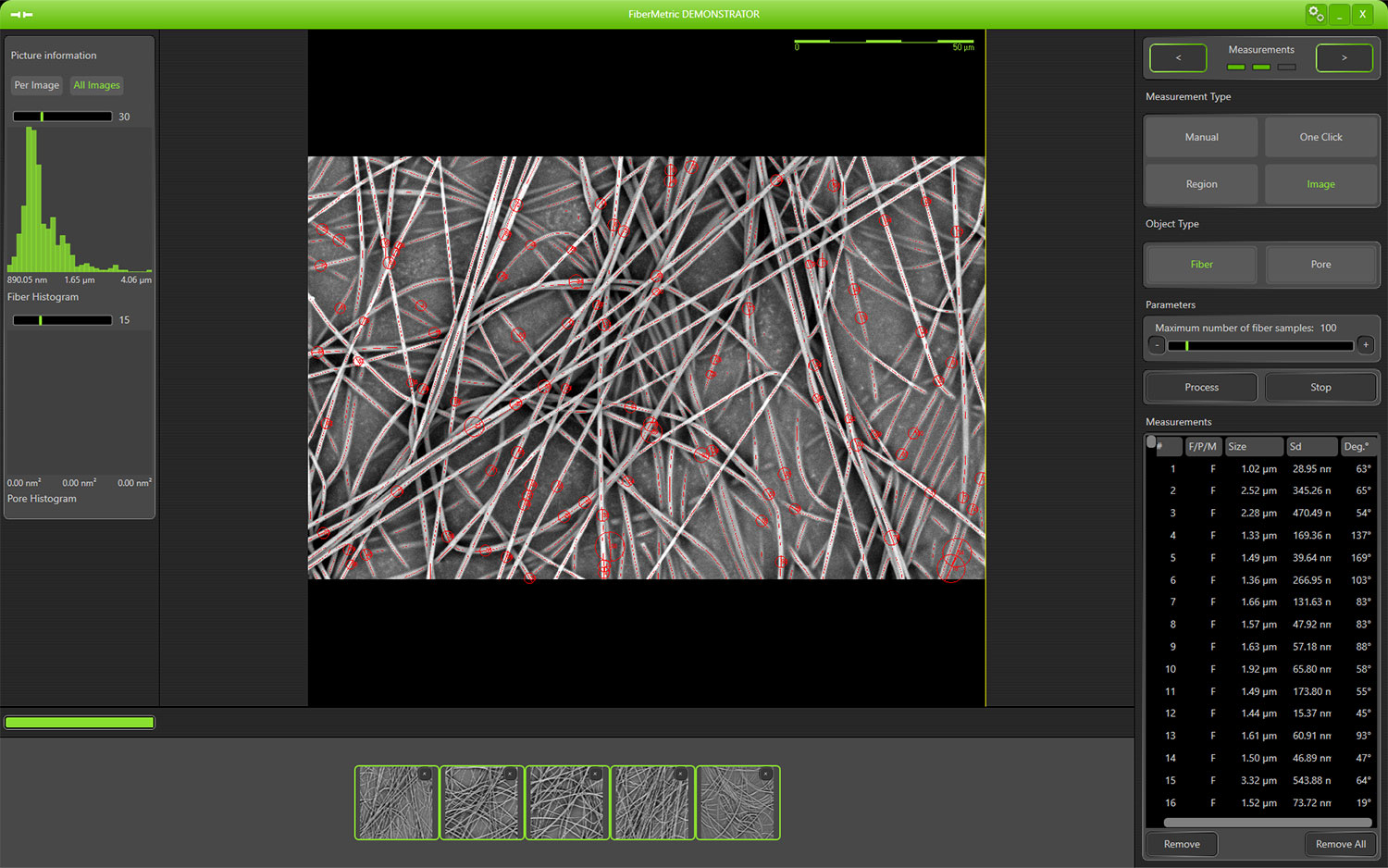

FiberMetric

Fiber Metric automates feature detection and analysis, delivering accurate size and orientational information from micro and nanofiber samples. With a push of a button, the software starts analyzing sizing, orientation, and porosity of SEM images containing fibers in seconds. In addition to more accurate data acquisition, the automated measurements of the FiberMetric application guarantees a fast return on investment, saving time with an operator independent and statistically significant solution.

Key Specifications

- Automated measurements of fiber diameter and orientation

- Fast collection of statistical data; up to 1000 measurements per image

- Export all data, either statistically or as a raw data file

- View and measure micro and nanofibers with unmatched accuracy

- Real-time Phenom operation

Phenom ProSuite Image Analysis Software

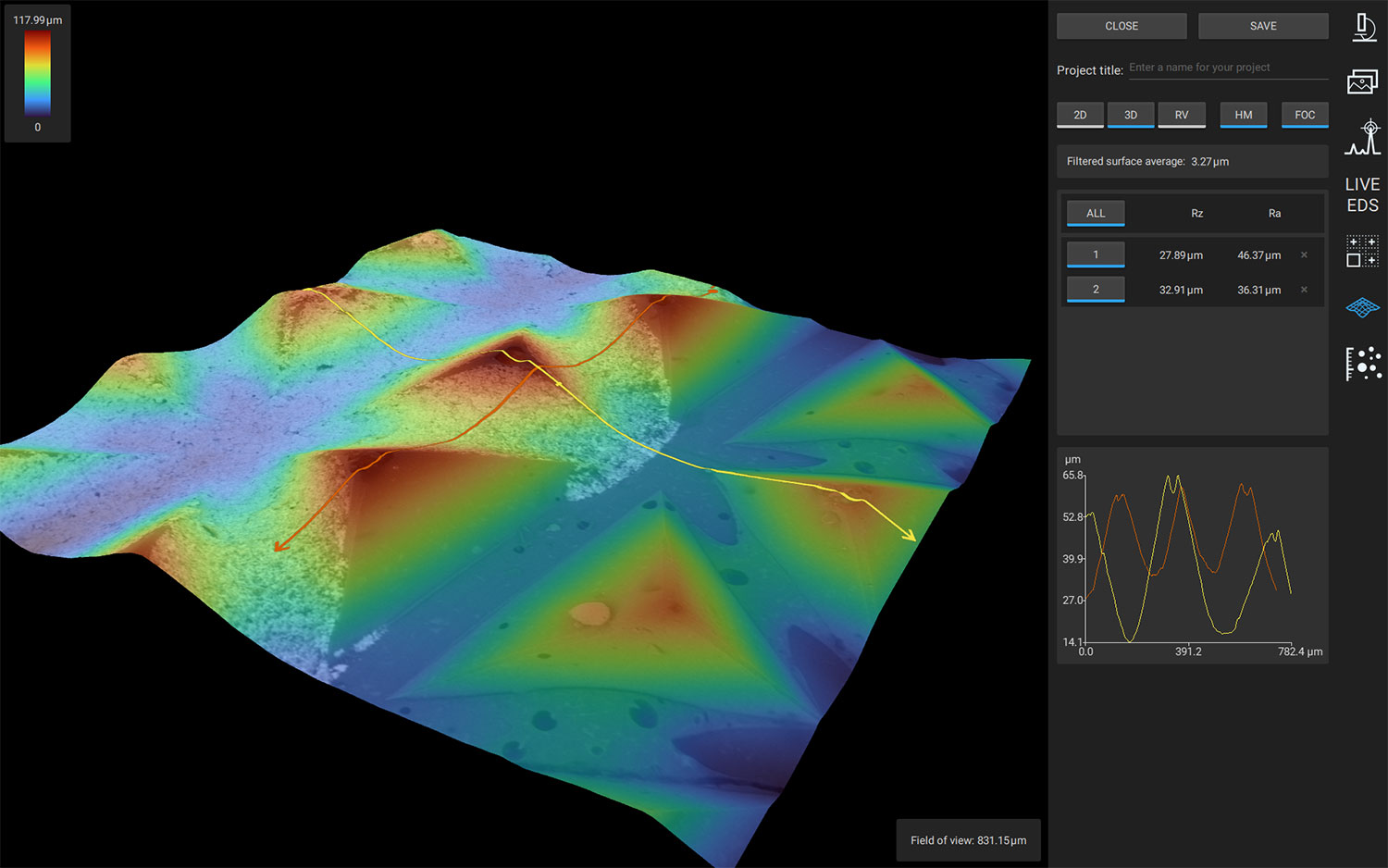

3D Roughness Reconstruction

The 3D Roughness Reconstruction application allows users to generate three dimensional images and sub-micrometer roughness measurements. Based on “shape from shading” technology using the four-segmented backscattered electron detector (BSD), 3D images help users interpret surface topography. The fully integrated software allows measurements of average roughness (Ra) and the roughness height (Rz). This is crucial for controlling and characterizing surface quality and texture of various types of samples.

Key Specifications

- Great for quality control, texture analysis, evidence characterization, defect/failure analysis, and wear analysis

- Higher resolution imaging compared to optical and mechanical measurement systems

- Intuitive fully automated user interface

- Fast reconstruction with no stage tilt required

- Create roughness maps and line profiles

- Field of view: 2 µm – 1 mm

Phenom ProSuite Software

Product Knowledgebase

Webinar

Using Automated SEM/EDS Analysis to Enhance Parts Cleanliness

Maintaining technical cleanliness is critical in industries where contamination can compro…

Blog

5 Reasons to Use a Desktop STEM to Screen Negatively Stained Samples

Cryo-electron microscopy (cryo-EM) is a powerful imaging technique used to determine the s…

White Paper

Phenom Pharos: A Compact Desktop STEM for Screening Negative Stained Samples

The Phenom Pharos Desktop SEM/STEM is a compact and affordable solution designed for cryo-…