Automated Cryo-EM Sample Preparation

Cryosol VitroJet™

VitroJet from Cryosol, is a fully automated cryo-EM sample preparation system designed to deliver high-throughput, reproducible vitrification with minimal user intervention. It integrates advanced technologies such as pin-printing, jet vitrification, plasma treatment, and inline imaging to optimize every stage of the grid preparation process. By enabling precise control over sample layer thickness and eliminating manual steps like blotting and clipping under liquid nitrogen, the VitroJet accelerates the cryo-EM workflow minimizing screening and improving reproducibility. Compatible with any commercially available grid, the VitroJet is a versatile creative solution that streamlines the path from sample to structure.

Pre-Clipped Autogrids

Jet vitrification allows the use for pre-clipped grids, minimizing grid damage

Ease & Automation

Makes all of the steps prior to microscopy into a low-cost, low-risk, and reproducible activity

Control Sample Thickness

Easily customize deposition settings and monitor with real-time visual feedback

Talk to an Instrumentation Specialist Today!

VitroJet: The Vitrification Revolution

VitroJet is a next-generation, fully automated vitrification platform designed to eliminate key bottlenecks in traditional cryo-EM sample preparation workflows. Engineered for high-throughput single particle analysis, VitroJet integrates several advanced technologies including pin printing, jet vitrification, and real-time viewing into a single streamlined system.

This intelligent automation enables precise control over sample layer thickness and improves the number of high-quality, data-ready holes on each grid. By simply adjusting the preparation protocol, users can tailor the process to optimize sample conditions for a wide variety of structural biology applications.

The VitroJet empowers cryo-EM scientists to obtain more reliable results & faster pipelines with less waste, and greater efficiency.

Cryosol VitroJet

Product Features

Automated Cryo-EM Sample Preparation

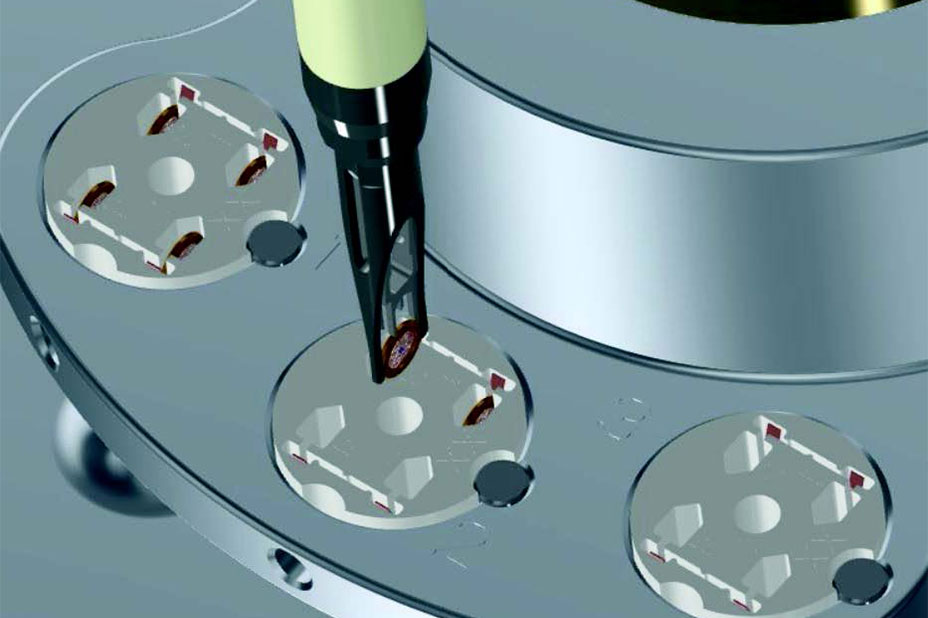

VitroJet streamlines the cryo-EM grid preparation process through a fully integrated, automated workflow designed for maximum reproducibility and minimal user dependence. Key built-in features such as plasma treatment and automatic grid handling ensure consistent, high-quality results across multiple runs. Since the system uses pre-clipped autogrids, the preparation of the grids requires minimal user intervention. By eliminating manual steps like post-clipping, VitroJet reduces the risk of sample damage and contamination, preserving the integrity of vitrified specimens.

Throughout the sample preparation process, users can set, fine-tune, and save critical parameters, enabling full control and repeatability. Protocols can be easily standardized and reloaded, allowing for faster setup, reducing human error, and enhancing reproducibility. By automating cryo-EM sample preparation, VitroJet not only improves workflow consistency, but also boosts lab productivity and helps accelerate structural biology research.

Pre-Clipping at Room Temperature

With room temperature pre-clipping of autogrids, the VitroJet eliminates the need for delicate manual operations traditionally performed under liquid nitrogen. This innovation significantly reduces the training burden and fine motor skills required for cryo-EM sample preparation.

Pre-clipped autogrids are fully compatible with any cryo-TEM equipped with an autoloader, enabling effortless transfer from sample preparation to imaging and accelerating your cryo-EM pipeline.

Integrated Glow Discharge for Consistent Grid Wettability

VitroJet’s built-in glow discharger delivers a precise and consistent method for enhancing grid surface wettability that is critical for optimal sample spreading during cryo-EM preparation. With adjustable discharge time, users can fine-tune conditions to match specific protocol requirements, ensuring repeatable results and greater flexibility across a range of sample types.

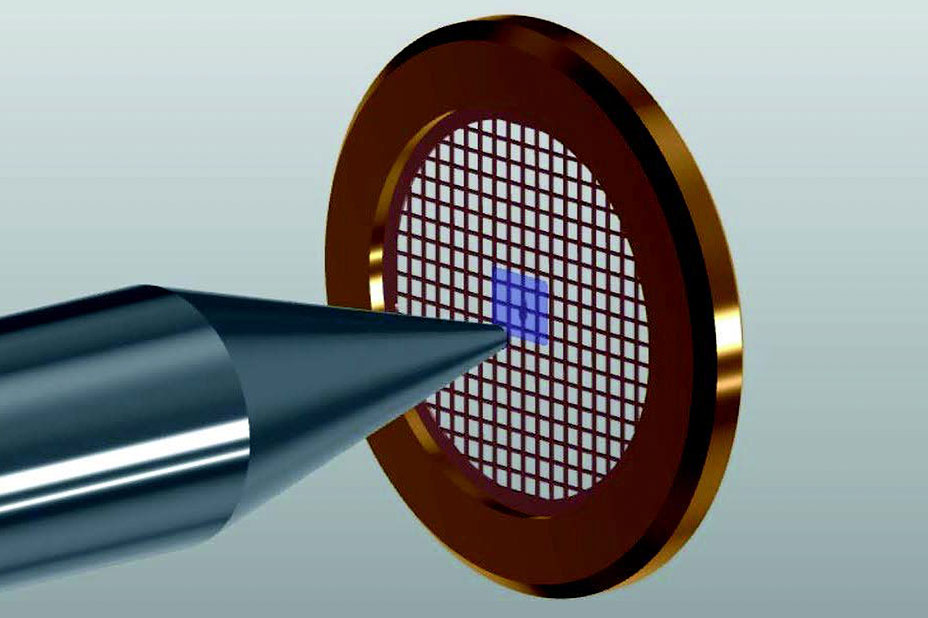

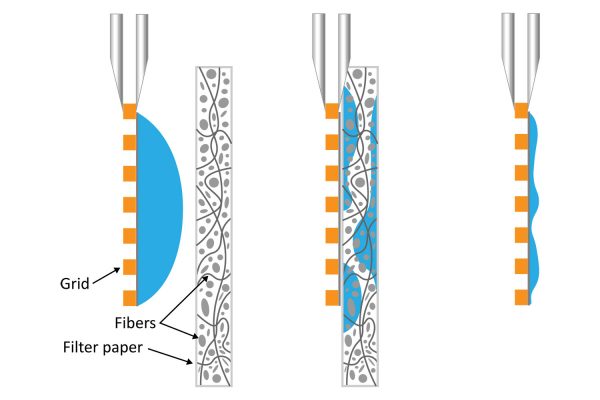

Pin-Printing Technology for Precise Sample Deposition

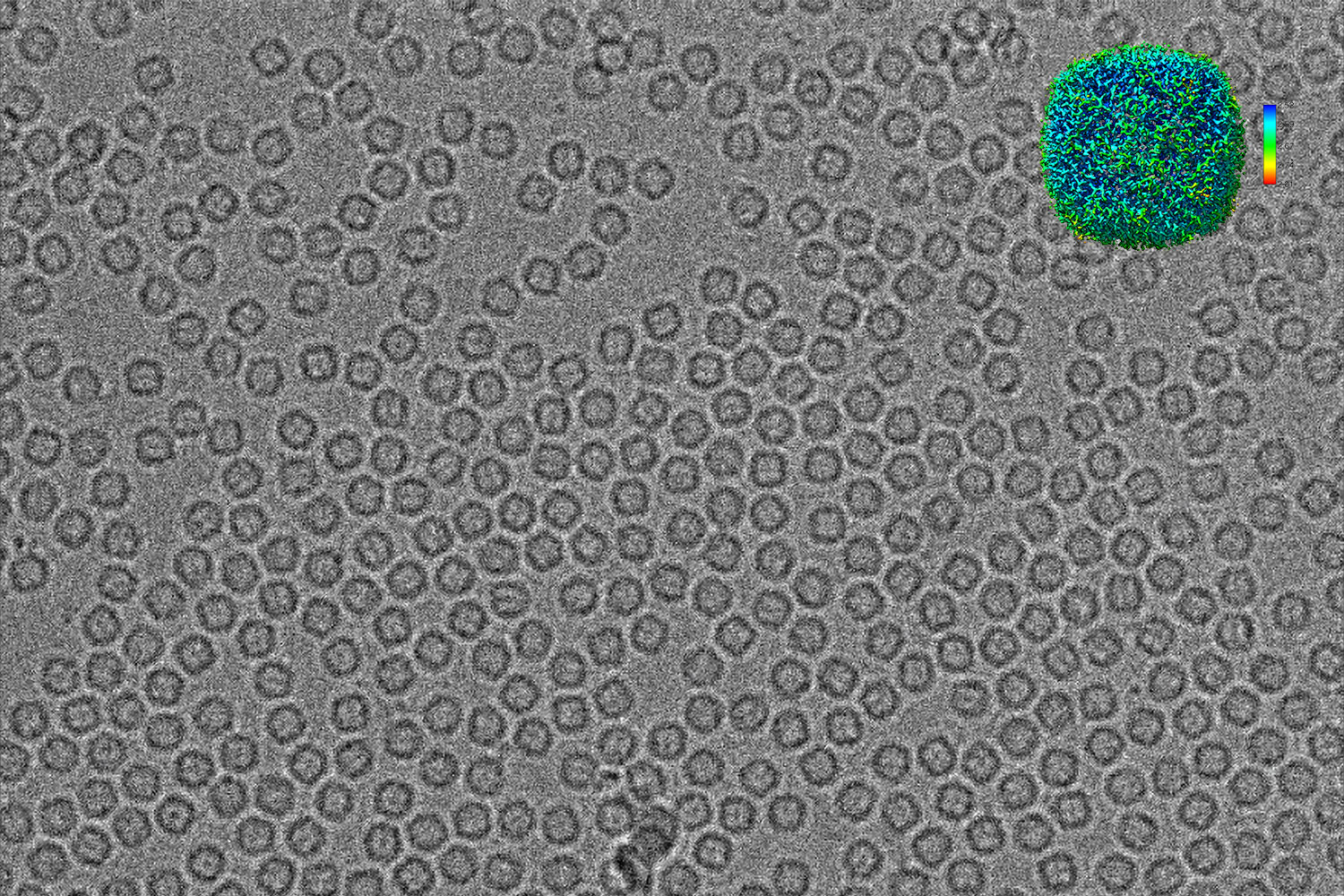

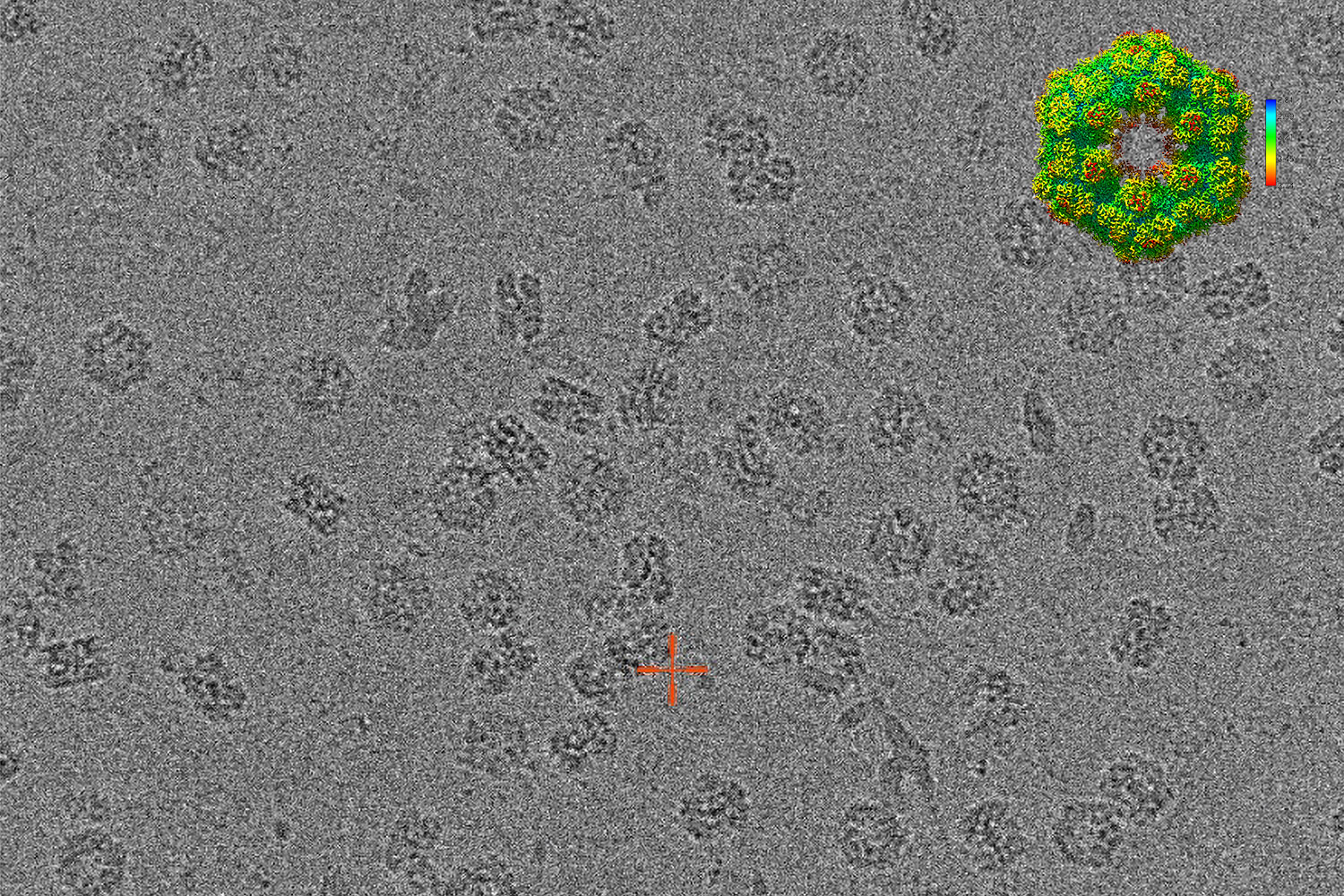

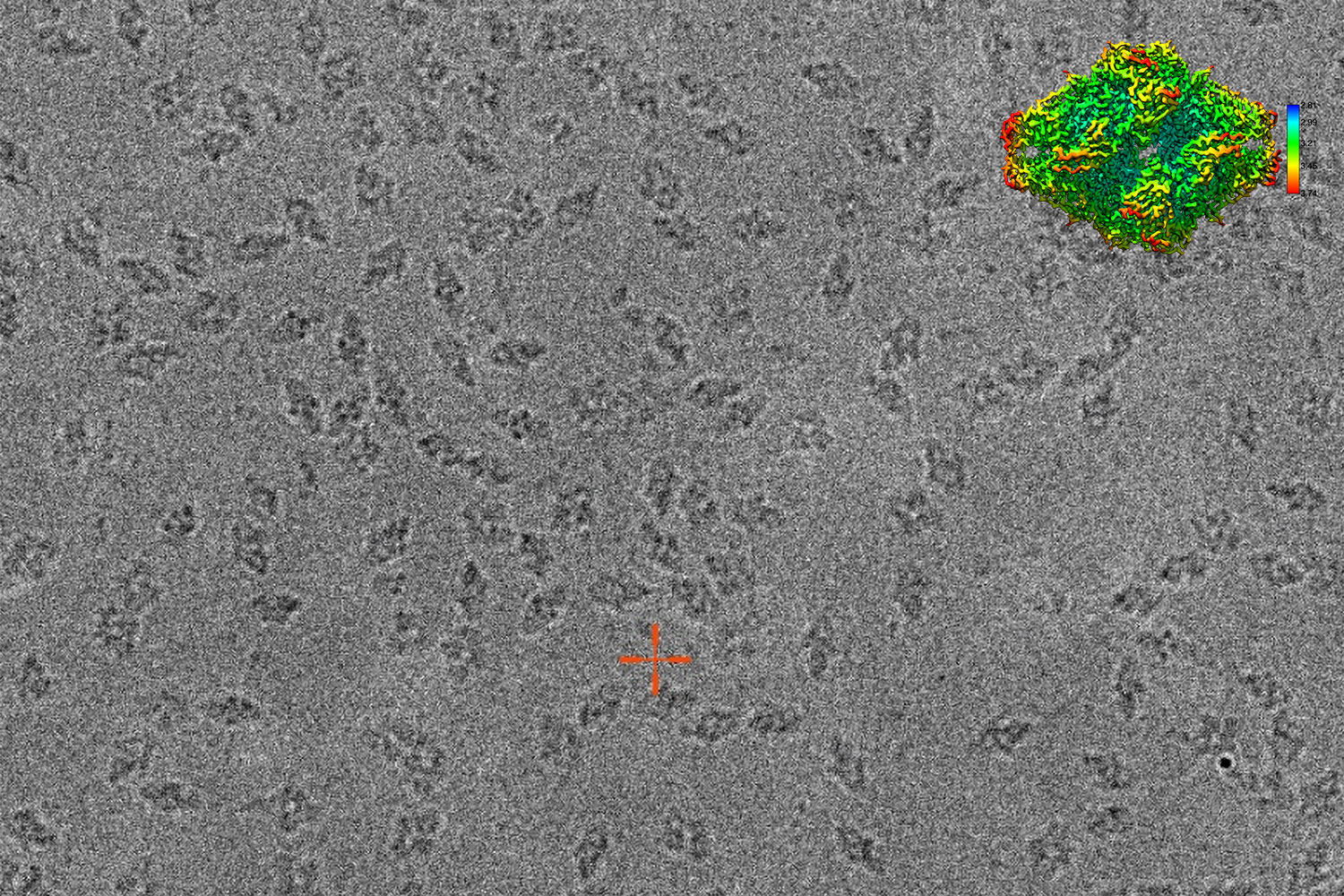

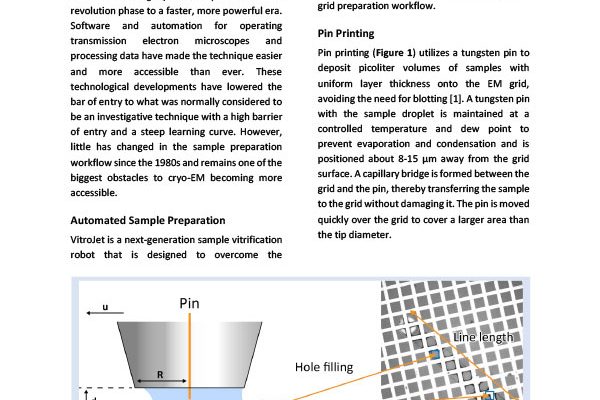

VitroJet’s unique blot-free pin-printing technology enables highly controlled deposition of ultra-thin sample layers using sub-nanoliter volumes. With nanometer-scale precision, the system delivers consistent and reproducible sample application directly onto the grid.

Key parameters such as writing velocity and pin-to-grid standoff distance, can be adjusted to finely tune the final layer thickness, making the process highly adaptable to different sample types and research needs. Integrated dewpoint control minimizes evaporation and condensation, ensuring stable environmental conditions throughout deposition.

By eliminating the need for conventional blotting, this approach reduces the risk of mechanical damage to both the sample and the grid, improving sample integrity and data quality for high-resolution cryo-EM.

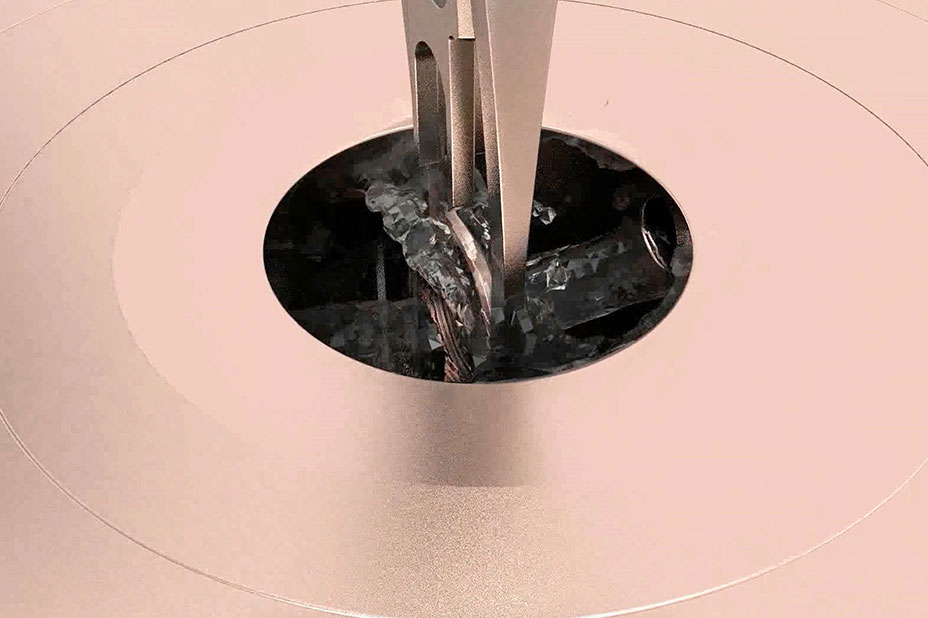

Jet Vitrification for Superior Cooling and Grid Integrity

VitroJet’s jet vitrification technology initiates rapid cooling at the center of the grid, ensuring that the sample vitrifies first. In traditional plunge freezing, the grid cools before the sample. This targeted approach improves vitrification quality and preserves sample structure.

The high cooling rates achieved through jet vitrification also make it possible to vitrify pre-clipped autogrids, expanding compatibility with modern cryo-EM workflows and eliminating the limitations of conventional freezing techniques.

Integrated High-Resolution Camera for Real-Time Monitoring

VitroJet features a built-in high-resolution camera that provides real-time visualization of the entire sample deposition process. This allows users to continuously monitor deposition quality, ensuring optimal sample placement before cryo-EM screening.

By validating sample quality upfront, researchers can reduce failed runs and accelerate time to results. All process data, including videos, images, and preparation settings, can be logged for documentation, reproducibility, and protocol refinement, supporting a more efficient and traceable cryo-EM workflow.

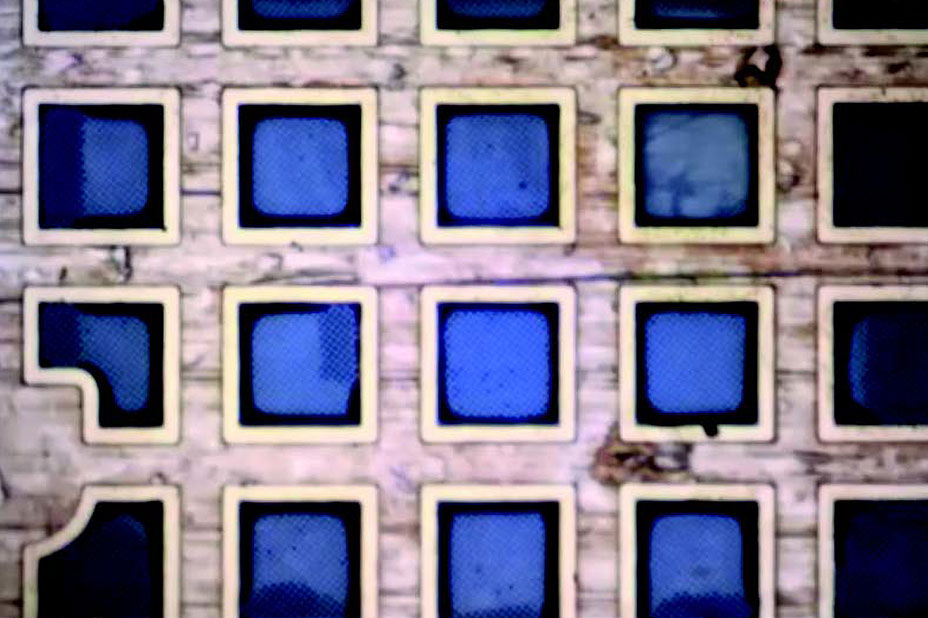

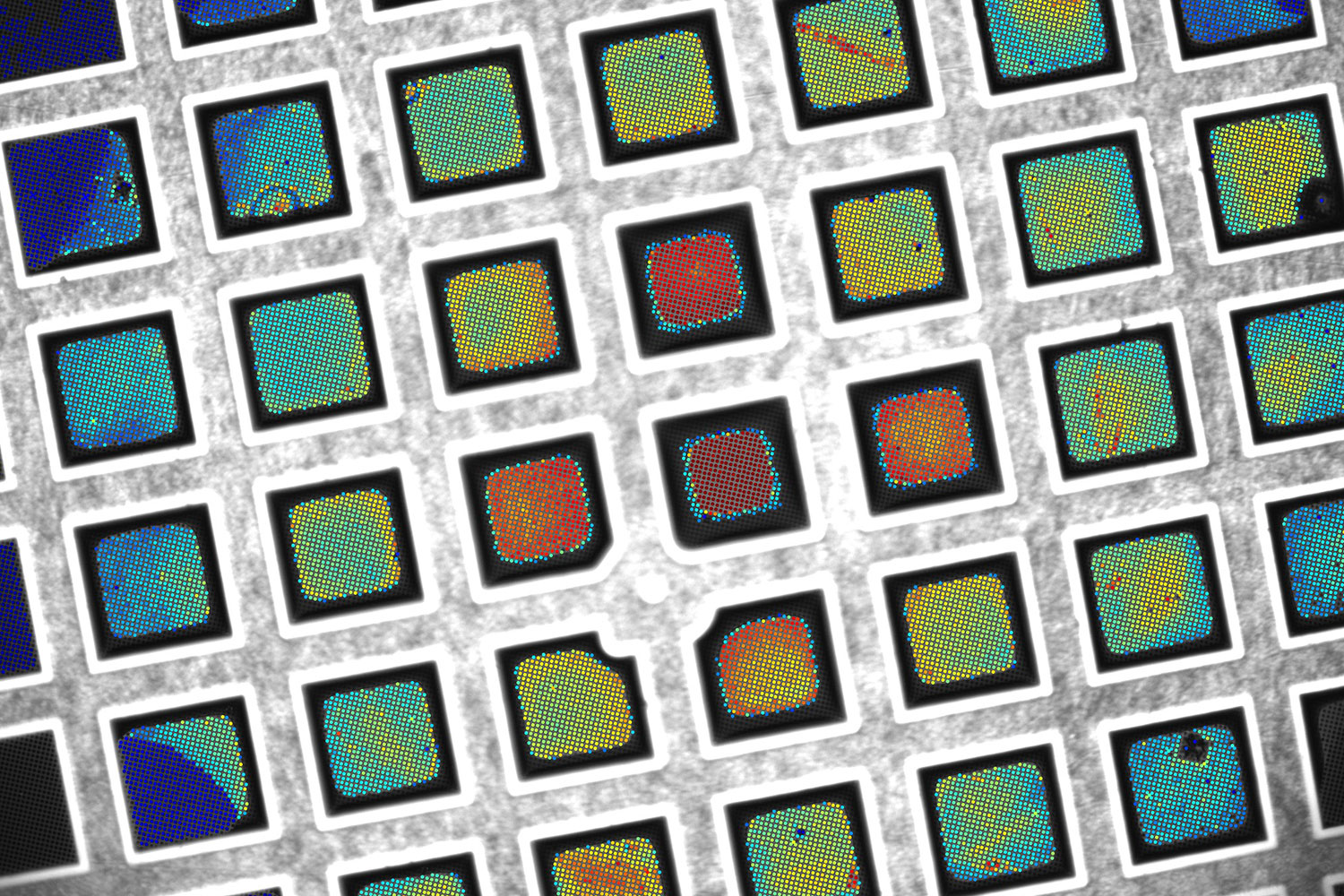

Ice Thickness Prediction for Efficient Grid Screening

A color-coded overlay provides immediate visual feedback: red indicates thicker regions, while dark blue highlights thinner, optimal areas. This intuitive visualization closely correlates with the atlas images produced by cryo-TEM, offering a reliable preview of usable holes before committing microscope time.

By pre-assessing grid quality, VitroJet enhances workflow efficiency, reduces resource consumption, and accelerates the sample preparation pipeline.

Cryosol VitroJet

VitroJet Applications

The VitroJet system is designed to support a wide range of applications in structural biology and cryo-electron microscopy (cryo-EM) by improving the quality, consistency, and throughput of sample vitrification. Its automation and precision make it ideal for Cryo-EM core facilities in academic and industrial structural biology research. VitroJet helps standardize and streamline sample preparation across multiple users and projects, making it ideal for multi-user cryo-EM facilities that require high reproducibility and minimal training overhead.

Single Particle Analysis (SPA):

VitroJet is optimized for preparing high-quality cryo-EM grids for single particle analysis, where consistent ice thickness and sample distribution are critical for resolving macromolecular structures at near-atomic resolution.

High-Throughput Drug Discovery:

With its automation and reproducibility, VitroJet supports high-throughput cryo-EM pipelines for screening drug candidates bound to protein targets, expediting early-stage drug discovery and structure-based design.

Cryo-Electron Tomography (Cryo-ET):

Although primarily designed for single particle workflows, VitroJet’s precision handling, thin-layer deposition, and speedy jet-vitrification can benefit diverse arrange of applications including cryo-ET and MicroED.

Cryo-EM Vitrojet

Product Knowledgebase

Webinar

VitroJet: Revolutionizing CryoEM Sample Prep

Moving beyond plunge freezing The increasing demand of CryoEM for producing high resolutio…

Blog

The Air Water Interface and Sample Preparation for Cryo-EM

The air-water interface (AWI) is essentially the chaotic boundary where a solution meets t…

White Paper

Overcoming the Learning Curve of CRYO-EM Sample Preparation

Advancements in cryogenic transmission electron microscopes coupled with recent breakthrou…